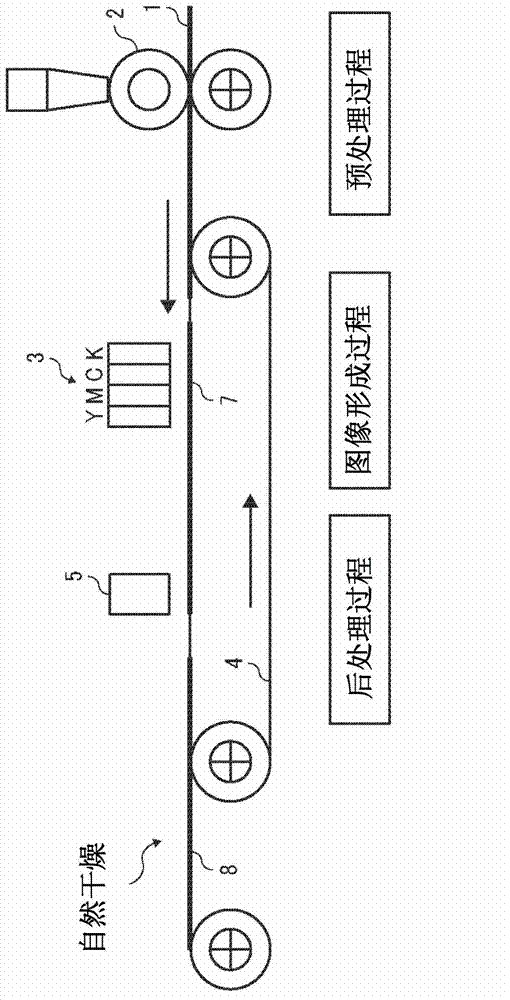

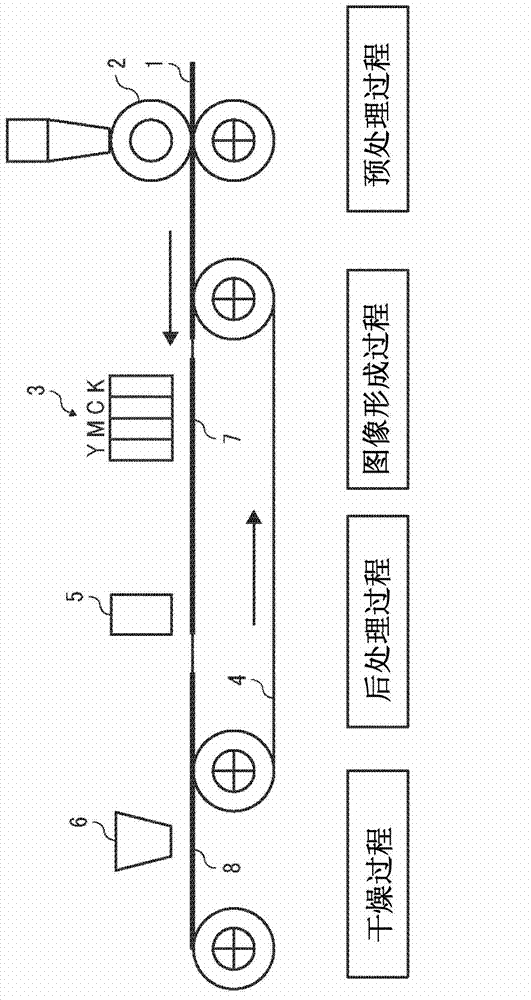

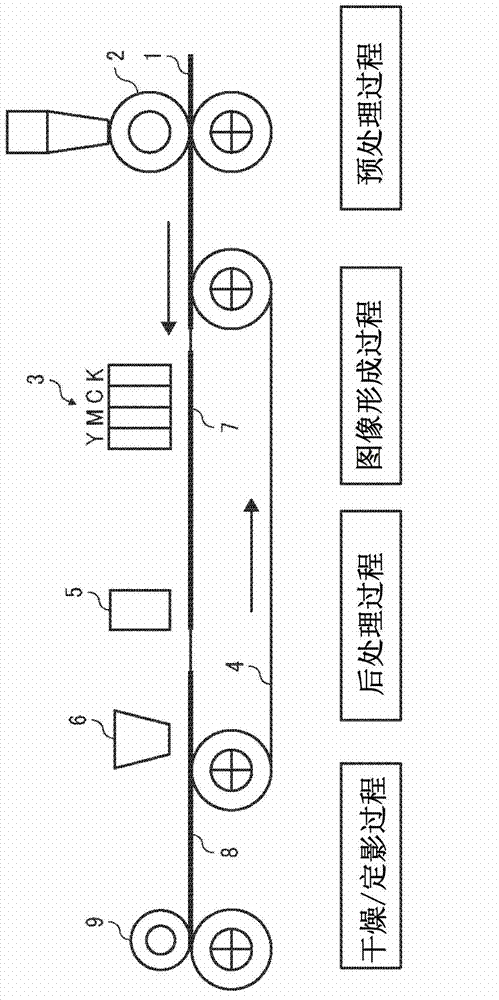

Image forming method

一种图像、预处理液体的技术,应用在复制/标记方法、印刷、油墨等方向,能够解决不环保、复杂结构等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0435] Preparation Example 1 (Preparation of Water-Soluble Polymer Solution A)

[0436] The following components (1)-(3) were stirred by a stirrer while heating them to dissolve the copolymer (1).

[0437] (1) α-olefin-maleic anhydride copolymer having the formula (a) mentioned below

[0438] 10.0 copies

[0439]

[0440] wherein R is an alkyl group having 18 to 22 carbon atoms, and n is an integer of 30 to 100.

[0441] (ie, T-YP112 from Seiko PMC Corp., having an acid value of 190 mgKOH / g and a weight average molecular weight of 100,000)

[0442] (2) 17.34 parts of 1N LiOH aqueous solution

[0443] (1.2 times the acid value of the copolymer (1))

[0444] (3) 72.66 parts of ion-exchanged water

[0445] The mixture was filtered using a filter having pores with an average diameter of 5 μm to prepare a water-soluble polymer solution A.

[0446] In this regard, an olefin having 20 to 24 carbon atoms is used to prepare a copolymer (...

preparation Embodiment 2

[0447] Preparation Example 2 (preparation of the black pigment dispersion of surface treatment)

[0448] Ninety (90) grams with 150m 2 Carbon black with a CTAB specific surface area per g and a DBP oil absorption value of 100ml / 100g was added to 3,000ml of 2.5N sodium sulfate solution, and the mixture was heated to 60°C while stirring at 300rpm for 10 hours to carry out the oxidation reaction. The reaction product was filtered, and the obtained carbon black was mixed with an aqueous sodium hydroxide solution to neutralize the carbon black, followed by ultrafiltration.

[0449] After washing the carbon black with water, the carbon black was dried. The dried carbon black was dispersed in pure water while sufficiently stirring to prepare a carbon black pigment dispersion. The carbon black pigment dispersion had a volume average particle diameter (D50) of 103 nm when the volume average particle diameter was measured with a particle size distribution measuring instrument, NANOTRA...

preparation Embodiment 3

[0450] Preparation Example 3 (Preparation of Magenta-Pigment-Containing Polymer Dispersion)

[0451] (1) Preparation of polymer solution A

[0452] After replacing the air in a 1-liter flask equipped with a mechanical stirrer, thermometer, nitrogen delivery tube, reflux tube and dropping funnel with nitrogen, the following components were put therein to prepare a mixture.

[0453]

[0454] Next, the following components were mixed and the mixture was dropped into the flask over 2.5 hours using a dropping funnel.

[0455]

[0456] Thereafter, a mixture of 0.8 g of azobismethylvaleronitrile and 18.0 g of methyl ethyl ketone was dropped into the flask over 0.5 hours using a dropping funnel.

[0457] After the reaction product in the flask was aged at 65° C. for 1 hour, 0.8 g of azobismethylvaleronitrile was charged into the flask, and the mixture was aged for another 1 hour.

[0458] After the reaction was completed, 364.0 g of methyl ethyl ketone was put into the flask. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com