The method for preparing etimicin sulfate

A technology for etimicin sulfate and etimicin sulfate, which is applied in the purification and preparation of high-purity etimicin sulfate, uses macroporous adsorption resin to separate and prepares etimicin sulfate, and can solve the problem of ammonia volatilization production and resin production. Regeneration is cumbersome, difficult to control and other problems, to achieve the effect of less organic solvent, low production cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 10.0 g of the crude product of etimicin in 200 ml of pure water (purity detected by HPLC is about 64%, and the concentration of the crude product is 50 mg / ml; it is carried out according to the method of the 2005 edition of the Pharmacopoeia, the same below), and the pH is adjusted to 9.0.

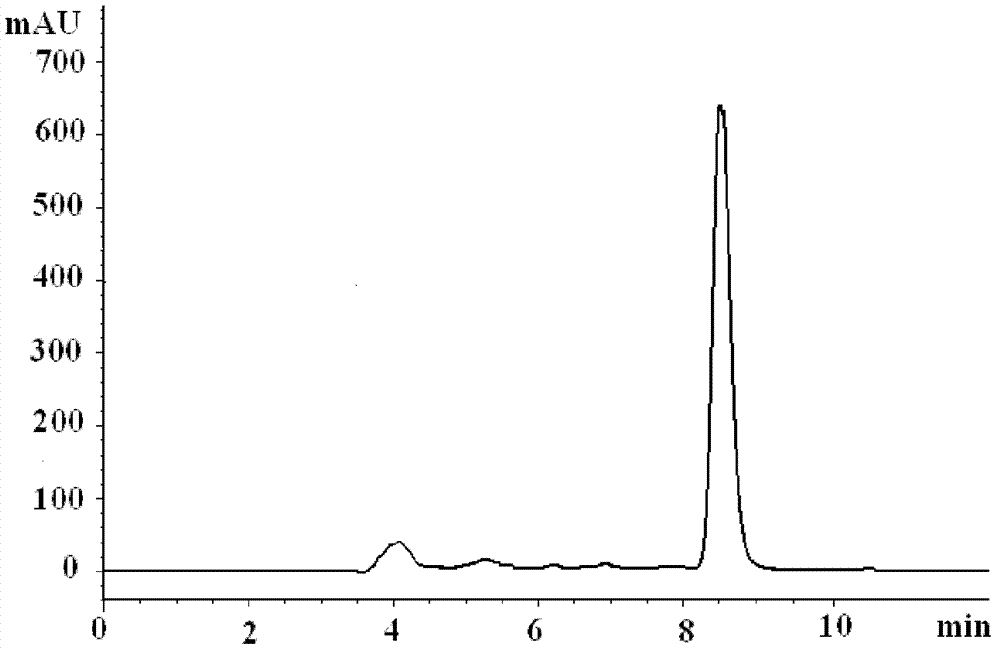

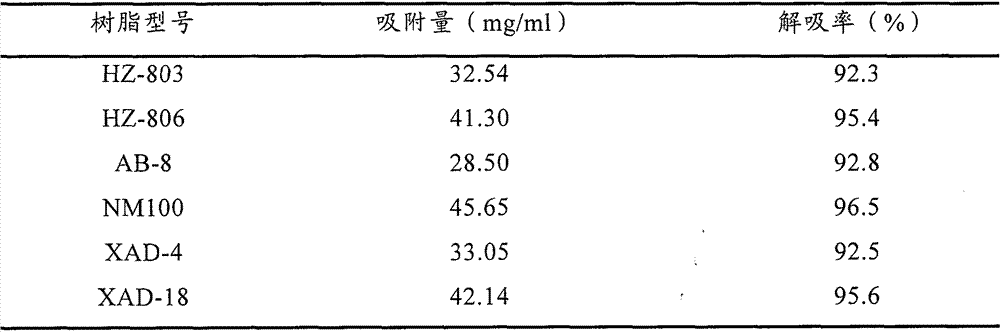

[0029] Install a HZ-806 adsorption resin column with a height of about 20 cm and a diameter of about 4 cm, and pass the above solution through the column at a flow rate of 10 ml / min, and a small amount of etimicin flows out. And use 2CV of pure water to wash away the salt and water-soluble impurities, and the etimicin will not leak out at this time. Then use 20CV of dilute sulfuric acid solution of pH 3.0 to elute impurities such as gentamicin C1a, and a small amount of etimicin sulfate will be washed out at this time. Finally, the column was eluted with a dilute sulfuric acid solution with pH 1.5, and the part with higher purity in the eluate was distributed and collected....

Embodiment 2

[0043] Dissolve 10.0 g of the crude product of etimicin in 200 ml of pure water (the detection purity is about 64%, the concentration of the crude product is 50 mg / ml), and the pH is adjusted to 10.8.

[0044] Install a HZ-806 adsorption resin column with a height of about 20 cm and a diameter of about 4 cm, pass the above solution through the column at a flow rate of 10 ml / min, and the etimicin is completely adsorbed on the column. And use 2CV of pure water to wash away the salt and water-soluble impurities, and the etimicin will not leak out at this time. Then use 20CV of dilute sulfuric acid solution of pH 3.0 to elute impurities such as gentamicin C1a, and a small amount of etimicin sulfate will be washed out at this time. Finally, the column was eluted with a dilute sulfuric acid solution of pH 1.5, and the part with higher purity in the eluate was distributed and collected. HPLC detection showed that the purity was 93.4%, and a large amount of pigment was removed. The c...

Embodiment 3

[0047] Dissolve 10.0 g of the crude product of etimicin in 200 ml of pure water (the detection purity is about 64%, the concentration of the crude product is 50 mg / ml), and the pH is adjusted to 12.0.

[0048] Install a HZ-806 adsorption resin column with a height of about 20 cm and a diameter of about 4 cm, pass the above solution through the column at a flow rate of 10 ml / min, and the etimicin is completely adsorbed on the column. And use 2CV of pure water to wash away the salt and water-soluble impurities, and the etimicin will not leak out at this time. Then use 20CV of dilute sulfuric acid solution of pH 3.0 to elute impurities such as gentamicin C1a, and a small amount of etimicin sulfate will be washed out at this time. Finally, the column was eluted with a dilute sulfuric acid solution with pH 1.5, and the part with higher purity in the eluate was distributed and collected. HPLC detection found that the purity was 93.1%, and a large amount of pigment was removed. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com