Distiller

A still and still pot technology, which is applied in the field of brandy distillation and still structure, can solve the problems of complex structure and inconvenient use, and achieve the effects of reasonable structural design, improving alcohol quality and saving fuel

Active Publication Date: 2013-07-10

刘霞

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Brandy is a distilled drinking wine. The existing brandy distillation equipment is a Charente pot still, which is mainly composed of a still pot, a preheater, and a condenser. Two distillations are required to produce original brandy with an alcohol content of more than 60%

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

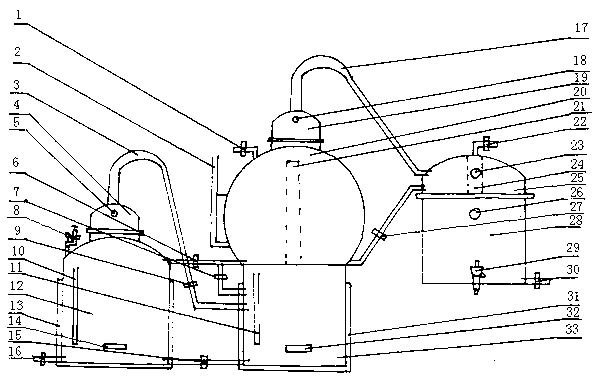

The invention relates to a distiller which is particularly applicable to distillation of brandy, and belongs to the technical field of distiller structures. The distiller comprises a first distillatory pot and a second distillatory pot which are provided with heating devices, a preheater mounted above the second distillatory pot, and a foreshot condenser used for condensing low-degree wine fume, wherein the first distillatory pot, the second distillatory pot, the preheater and the foreshot condenser are communicated by pipelines provided with dump valves; a first return device and a second return device are mounted on the first distillatory pot and the preheater respectively, and are communicated with the second distillatory pot and the foreshot condenser through pipelines respectively; a wine fume return pipe communicated with the second distillatory pot is mounted in the preheater; a feed valve is mounted on the preheater; a condenser used for condensing high-degree wine fume is mounted below the foreshot condenser; and a wine measuring device and a water inlet valve are mounted on the condenser. The distiller is reasonable in structural design and convenient to use, and the original brandy with the alcohol concentration above 60% can be prepared by once distillation.

Description

technical field [0001] The invention relates to a distiller, which is particularly suitable for brandy distillation and belongs to the technical field of distiller structure. Background technique [0002] Brandy is a distilled drinking wine. The existing brandy distillation equipment is a Charente pot still, which is mainly composed of a still, a preheater and a condenser. It has a complex structure and is inconvenient to use. Two distillations are required to obtain the original brandy with an alcohol content of more than 60%. SUMMARY OF THE INVENTION The object of the present invention is to solve the deficiencies of the above-mentioned prior art, and to provide a distiller with reasonable structure design, convenient use, and the ability to obtain original brandy with an alcohol content of more than 60% by only one distillation. The present invention is achieved through the following technical solutions: The distiller is characterized by comprising a first still p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12G3/12C12H6/02

Inventor 刘霞

Owner 刘霞

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com