Rail Transit Vehicle Gearbox

A technology for rail transit vehicles and gearboxes, which is applied in the directions of belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problems of unfavorable assembly of other components, inconvenient assembly and production, increase measurement errors, etc., to achieve convenient installation and Maintenance, convenient measurement, the effect of preventing oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

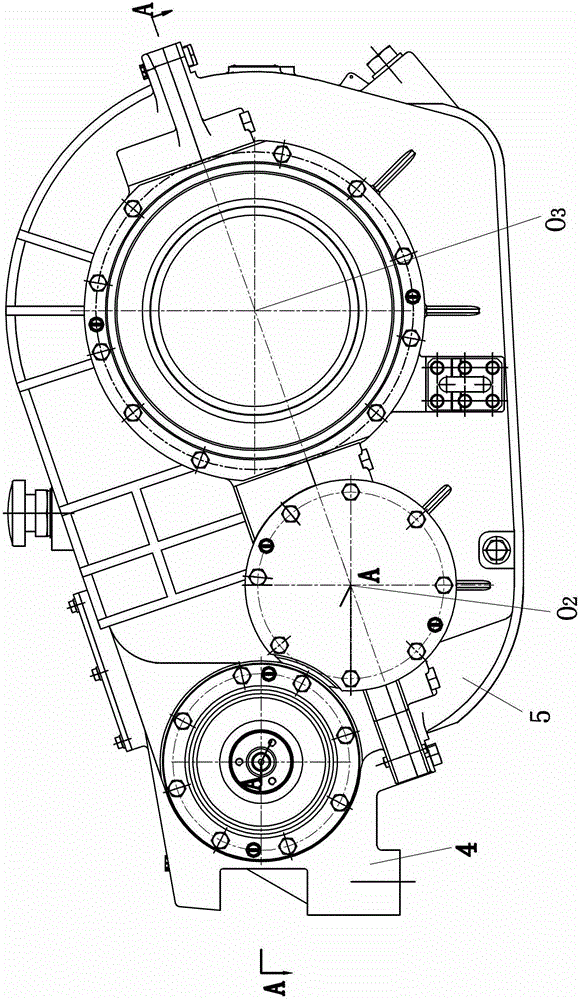

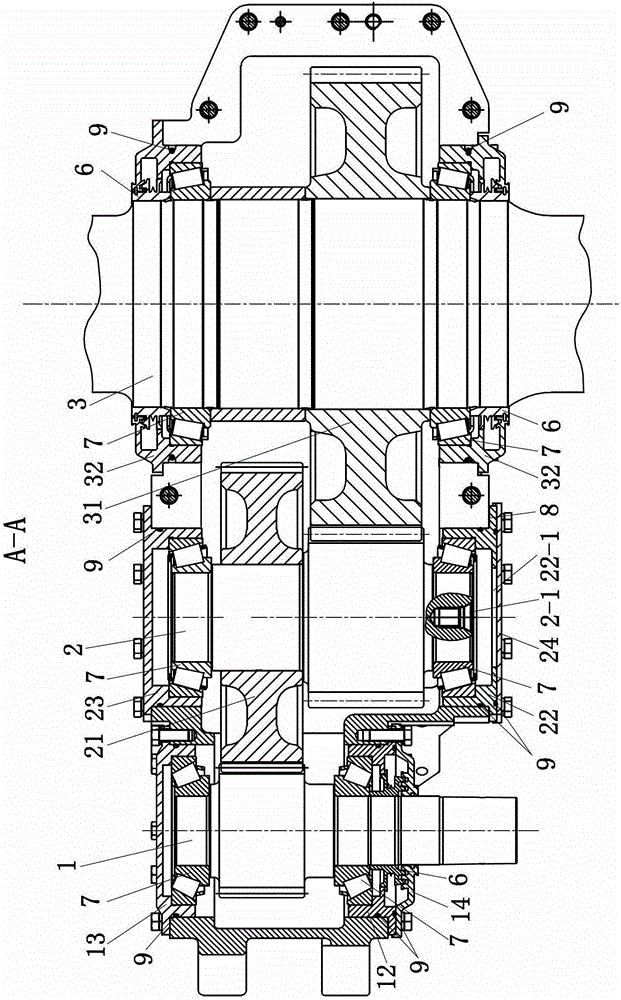

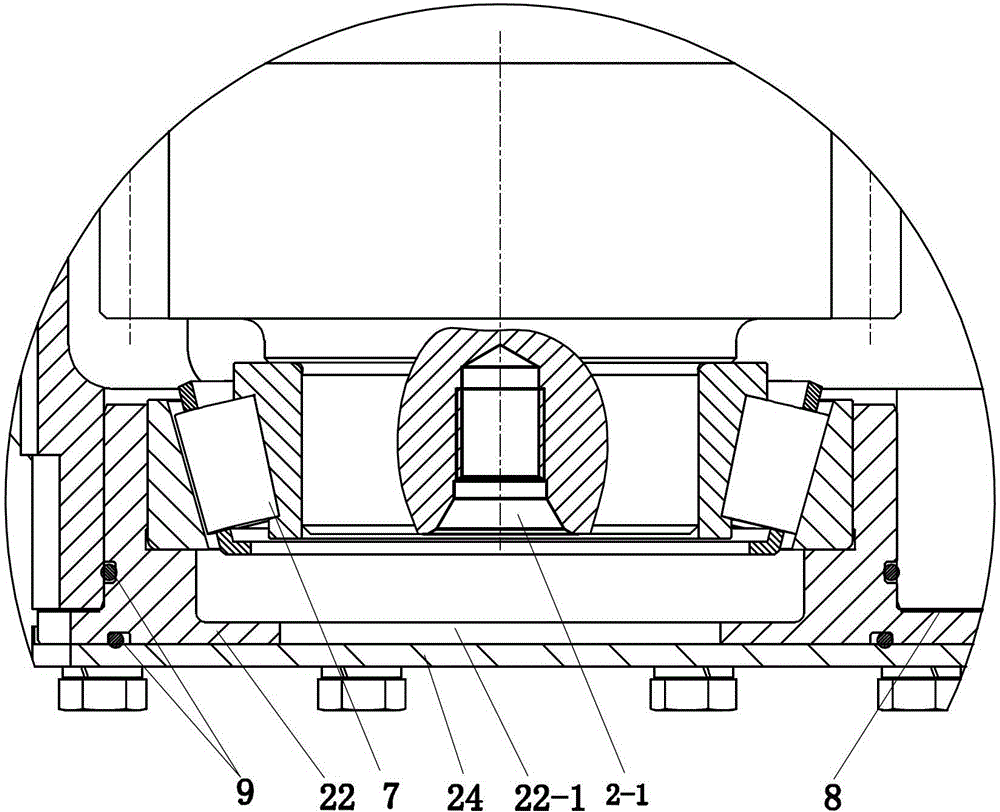

[0021] Referring to the accompanying drawings, this embodiment includes a driving shaft 1, an intermediate shaft 2, a driven shaft 3 and a casing. The box body is composed of an upper box body 4 and a lower box body 5, the joint surface of the upper box body 4 and the lower box body 5 passes through the axis line O2 of the intermediate shaft 2 and the axis line O3 of the driven shaft 3, and the upper box body The body 4 and the lower box body 5 are connected in the form of a flange, and the upper and lower boxes are fixedly connected by 12 bolts. The driving shaft 1 , the intermediate shaft 2 and the driven shaft 3 are arranged in parallel in the casing, wherein the driving shaft 1 is in the upper casing 4 . Both the drive shaft 1 and the intermediate shaft 2 are gear shafts, the intermediate shaft 2 is fixed with a primary driven gear 21, the driven shaft 3 is fixed with a secondary driven gear 31, the gear on the drive shaft 1 and the primary driven gear 21 meshes, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com