Automated sealing test machine

A sealing test and product technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, detecting the appearance of fluid at the leakage point, etc., can solve the problems of long manual operation time, short pressure holding time, low production efficiency, etc. , to achieve the effect of improving the efficiency of pressure testing, increasing the qualified rate of pressure testing, and reducing the physical exertion of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

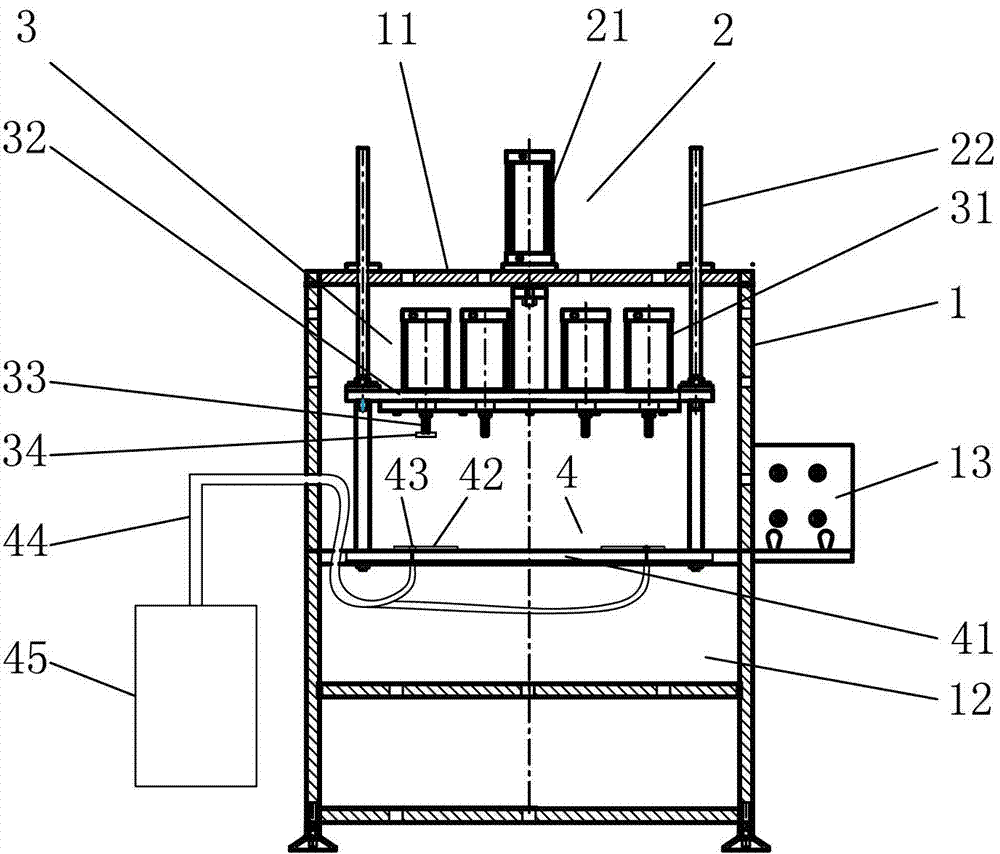

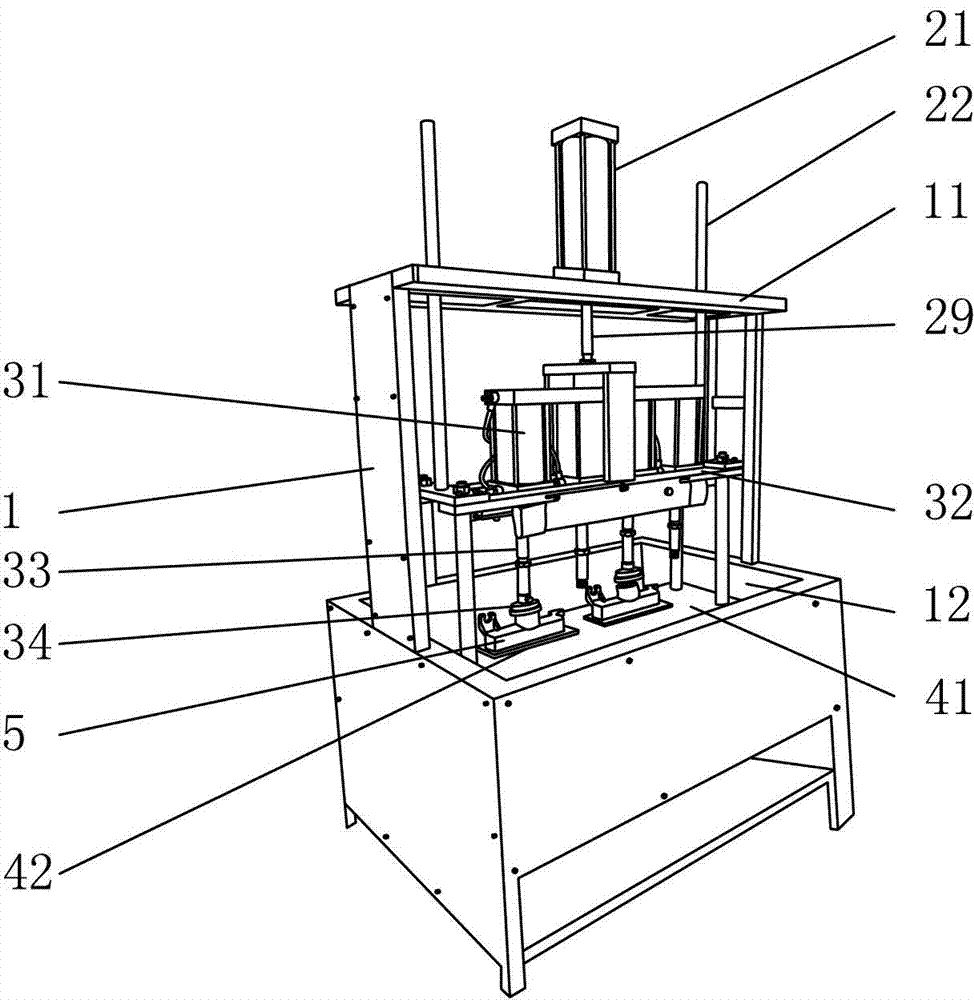

[0024] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 6 :

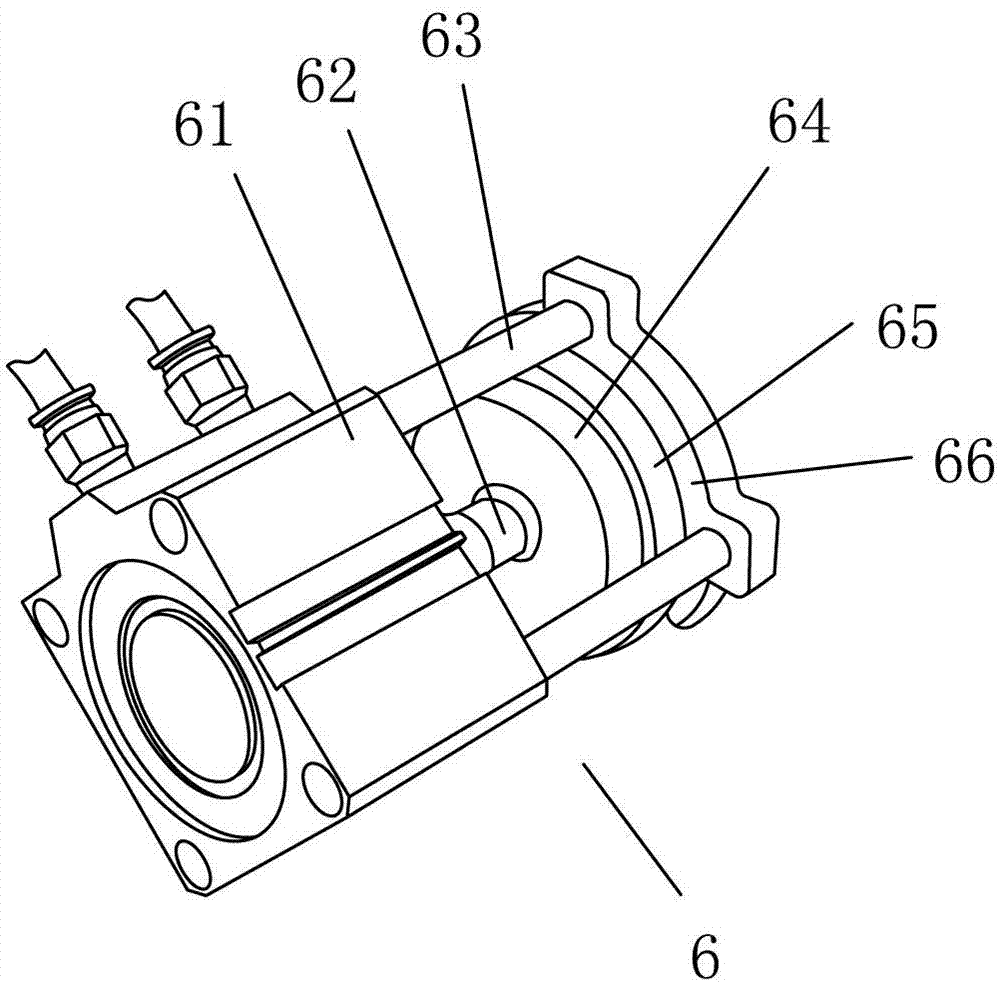

[0025] The automatic sealing test machine is equipped with a sealing test pool 12 on the lower part of the frame 1, a lifting device 2 on the upper part, and a product display rack 4 and a product pressing device 3 on the lower side of the lifting device 2. Or one side of the product display frame 4 is provided with a nozzle cover 6, and the lifting device 2 can drive the product display frame 4 and the product pressing device 3 into the sealing test pool 12, and the controller 13 controls the lifting device 2 , the action of the pressing device 3 and the air supply or exhaust for the nozzle cover 6.

[0026] The specific structure of the above-mentioned lifting device 2 is: the beam 11 on the top of the frame 1 is centered with a lifting cylinder 21, and the beams 11 on both sides of the lifting cylinder 21 are symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com