Fabrication of metal hard masks

A metal hard mask, hard mask technology, applied in metal material coating process, semiconductor/solid-state device manufacturing, gaseous chemical plating, etc., can solve the problems of thermal budget, pattern distortion, etc., to improve thermal budget, Effects of Maintaining Device Performance and Ensuring High-k Integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

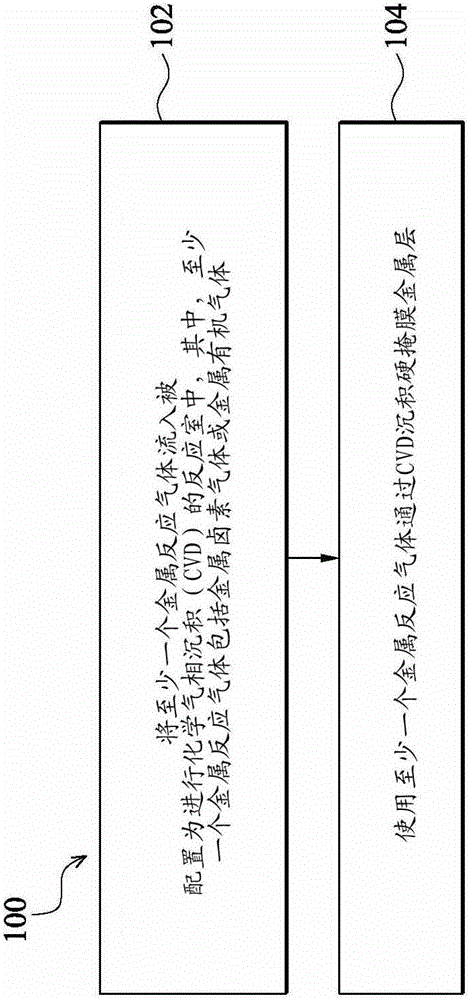

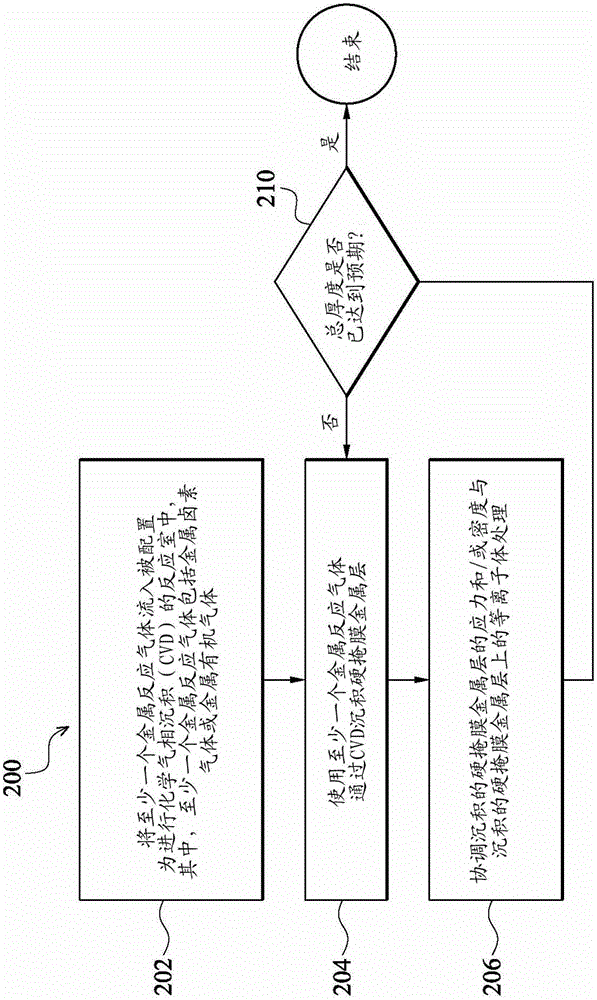

Method used

Image

Examples

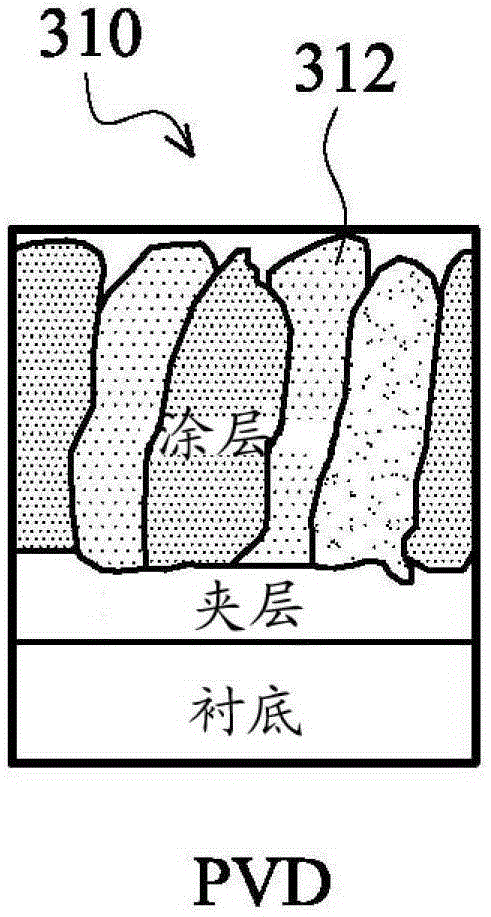

Embodiment Construction

[0031] It is understood that in order to implement the different components of the present invention, the following disclosure provides many different embodiments or examples. Specific examples of elements and settings described below are used to simplify the present disclosure. Of course, these are just examples and are not meant to be limiting. Furthermore, the first part formed on the second part in the following description may include an embodiment in which the first and second parts are formed in direct contact, or may include forming an additional part to be inserted into the first and second parts, So that the first and second components do not directly contact an embodiment. For simplicity and clarity, various components can be drawn in different sizes at will. In addition, some drawings have been simplified for clarity. Therefore, the drawings may not depict all components of a given apparatus (e.g., device) or method.

[0032] The accompanying drawings schematicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com