Wire deicing device

A wire and transmission technology, applied in the field of wire de-icing, can solve the problems of secondary icing, ineffective de-icing, incomplete de-icing, etc., and achieves the effect of good effect, ensuring stability and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

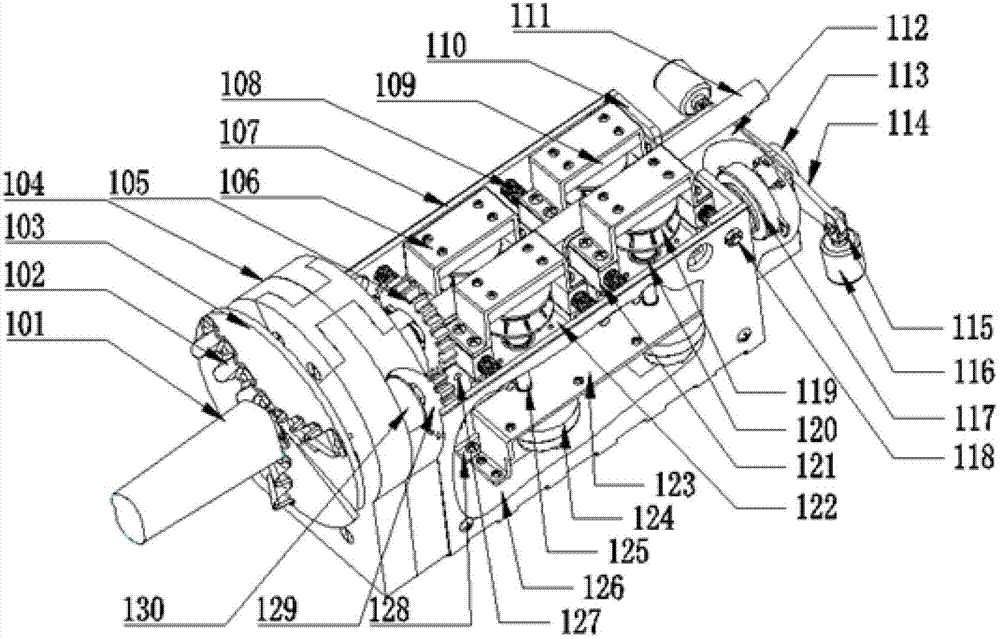

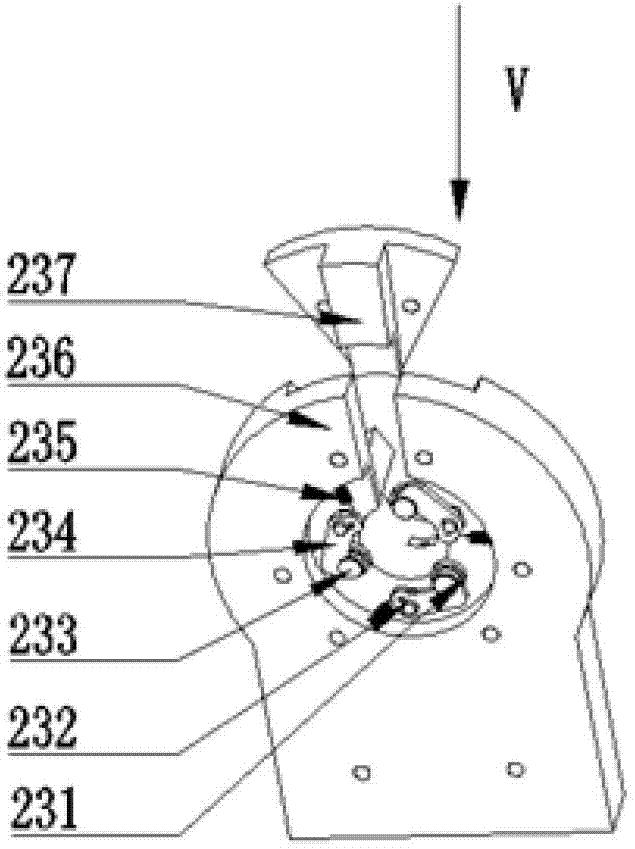

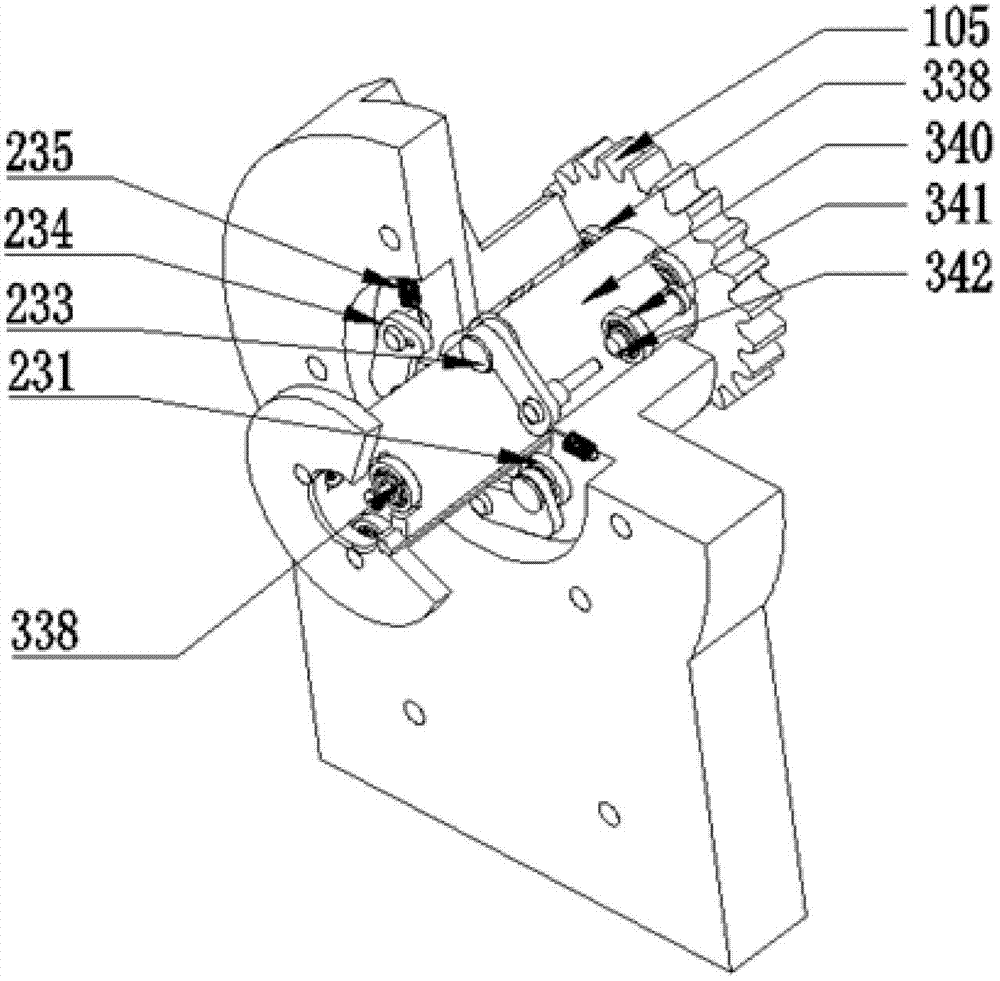

[0038] Such as figure 1 , Figure 7 , the wire deicing device of the present embodiment includes a frame structure housing composed of lateral side plates 107, vertical side plates 110 and bottom plate 126, provides power for the entire device, and travels the traveling mechanism 702 that makes the device travel on the wires 111. A deicing mechanism that implements different intensities of deicing at different positions of the wires.

[0039] Specifically, combine figure 1 , Figure 6 , the traveling mechanism 702 is set as several pairs of clamping parts 601 oppositely arranged, and the clamping parts include the upper frame body 106 and the lower frame body 123 of several types of structures, the upper backing plate 109 and the lower pad arranged in the depressions of the upper and lower frame bodies The transmission shaft 125 between the plates 122, the transmission shaft 125 is slidingly combined with the upper and lower backing plates through the bearing 120; the trave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com