Conical paper cone without center hole and loudspeaker with conical paper cone

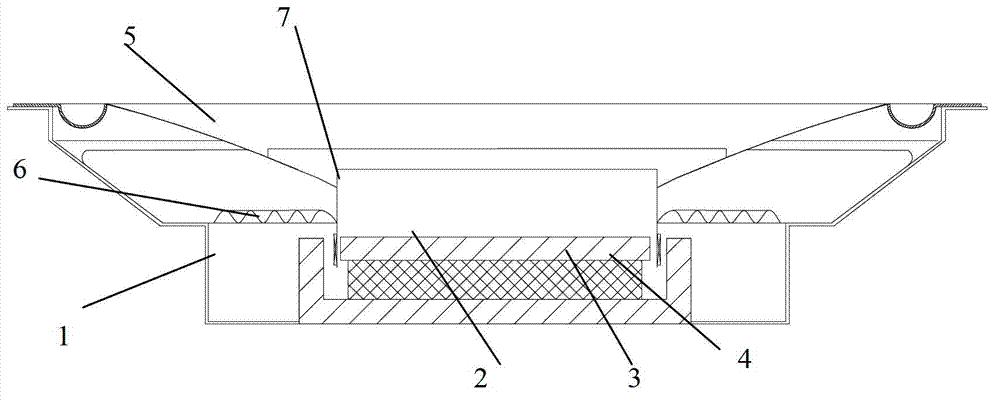

A center hole and loudspeaker technology, applied in the field of loudspeakers, can solve the problems of increased manufacturing cost, loudspeaker assembly burden, increased loudspeaker components, etc., and achieve the effects of improving quality stability, saving component costs and assembly costs, and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

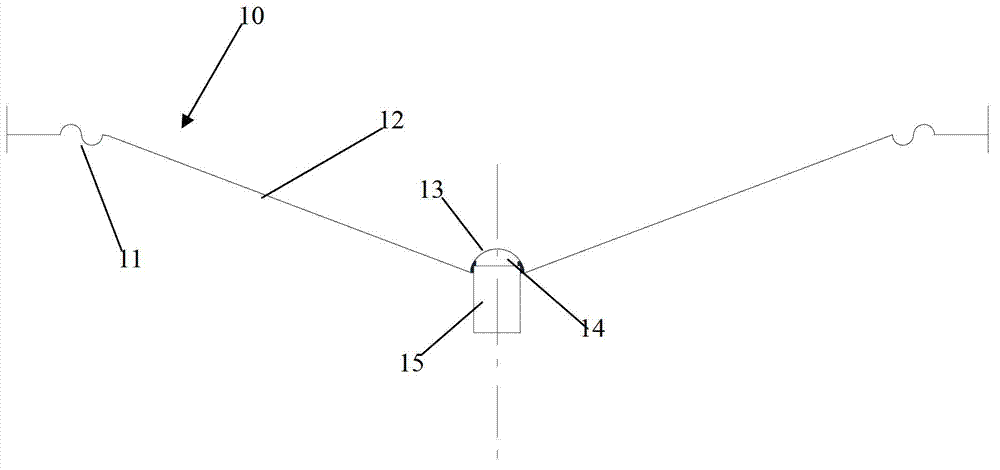

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0018] Such as figure 2 As shown, the conical paper cone 10 without a central hole of the present invention includes a ring 11 and a diaphragm 12, and the center of the diaphragm protrudes upwards to form a bulge 13 to form a connection cavity 14 on the lower surface of the diaphragm center . The surrounding ring 11 provides expansion and contraction and guidance for the vibration of the diaphragm 12 , which is similar to the prior art and will not be described here. The center of the diaphragm protrudes upwards to form a bulge. The top surface of the bulge is spherical, and the spherical surface can effectively reduce the accumulation of dust on it and avoid affecting the speaker. The connecting cavity is formed by connecting the outer edge of the dome and the vertical side of the diaphragm. The connecting cavity is shaped to match the voice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com