Paper cone for sound system

A sound system and paper cone technology, applied in the direction of diaphragm structure, planar diaphragm, diaphragm extension, etc., can solve the problems of increased manufacturing cost, coil heating and burning, and increased number of paper cone connecting parts, so as to save assembly cost, Reduce the bonding area and avoid the effect of heat and burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

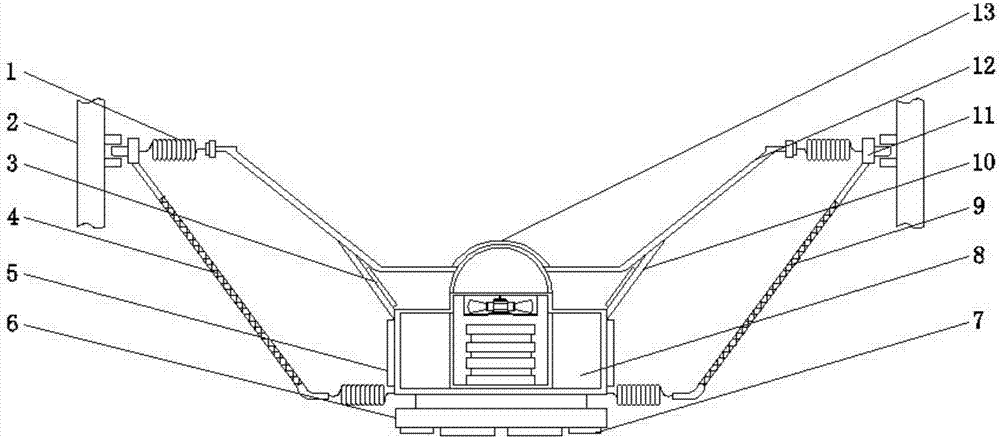

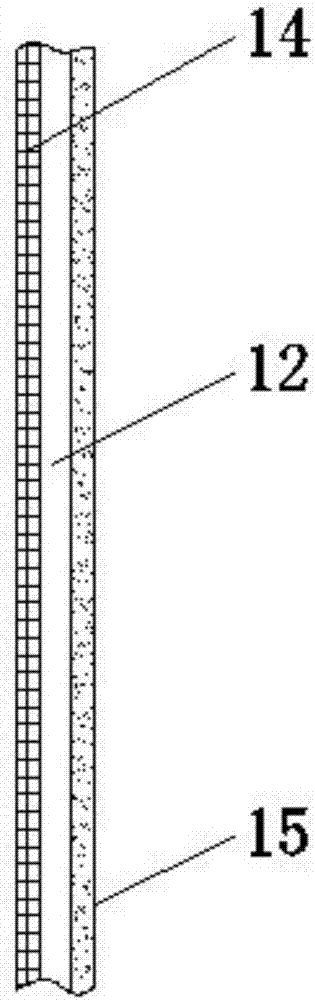

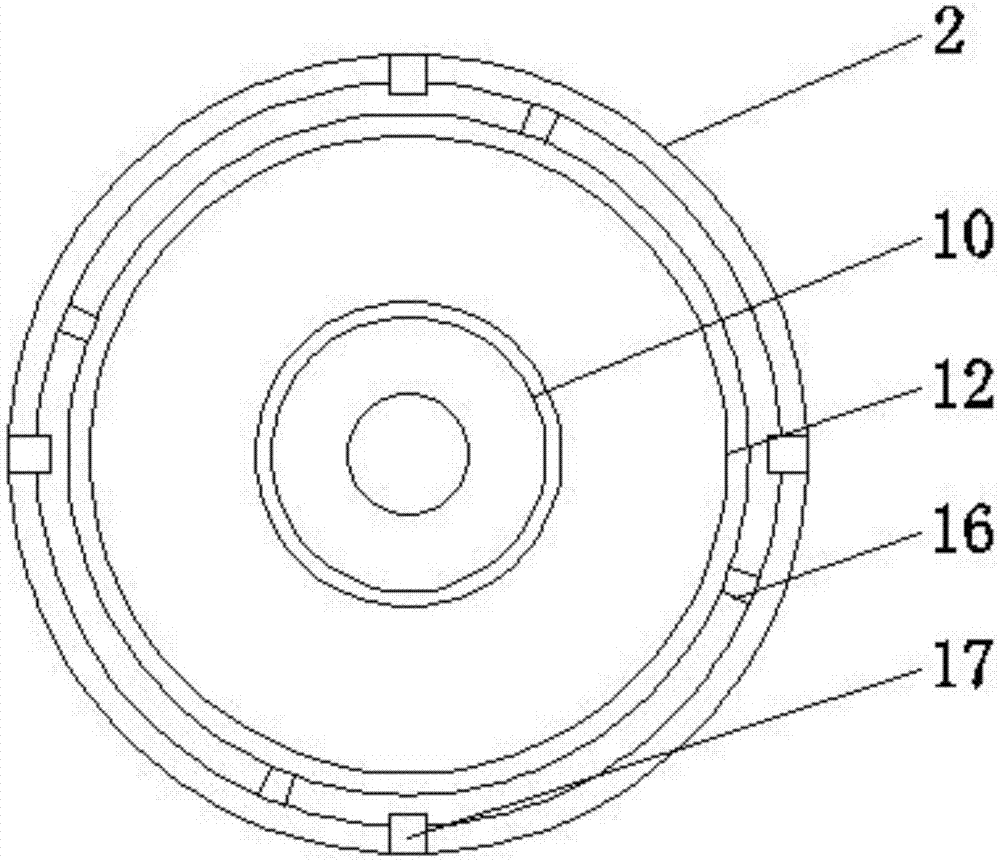

[0019] Such as Figure 1 to Figure 4 As shown, a paper cone for an audio system includes a membrane 3, a paper cone protection frame 4, a mounting flange 6 and a diaphragm 12, and the bottom of the mounting flange 6 is provided with installation limit holes of different sizes 7, so that it is possible to install the paper cones inside different paper cone installation frames, the top of the mounting flange 6 is evenly installed with a second return spring 21, and the end of the second return spring 21 away from the installation flange 6 is installed with a paper cone protection Frame 4, both sides of the paper cone protection frame 4 are evenly provided with ventilation holes 9 to assist in dissipating the excessive heat generated by the coil, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com