Electric-leakage-preventing carbon fiber heating plate

A carbon fiber heating and carbon fiber technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems affecting normal use and safety, easy virtual connection between copper tape and carbon fiber paper, stable use, and low safety performance. Achieve good heating effect, improve safety performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

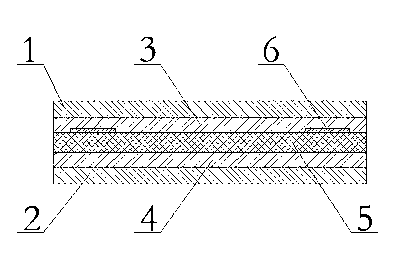

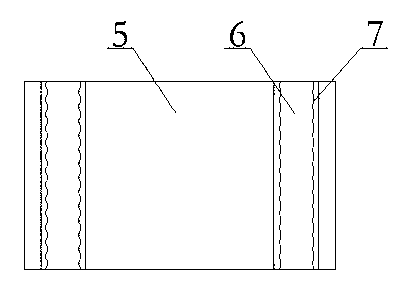

[0021] figure 1 , 2 As shown, a leakage-proof carbon fiber heating plate includes an upper metal layer 1, a lower metal layer 2, an upper insulation reinforcement layer 3, a lower insulation reinforcement layer 4, a carbon fiber conductive layer 5, a copper strip 6 and a suture 7. The carbon fiber conductive layer 5 and the copper strip 6 are pressed between the upper and lower insulation reinforcement layers 3 and 4, the upper insulation reinforcement layer 3 is provided with an upper metal layer 1, and the lower insulation reinforcement layer 4 is provided with a lower metal layer 2. The metal layer 1 and the lower metal layer 2 are connected to the ground / zero connection; the two sides of the copper strip 6 are stitched on the carbon fiber conductive layer 5 in a straight line along the extending direction of the copper strip through two sutures 7; the carbon fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com