Production technology of corn lactic acid fermentation drink

A production process and a technology of lactic acid fermentation, applied in the field of production technology of corn lactic acid fermented beverage, can solve the problems such as no literature report and practical application of the production technology of corn lactic acid fermented beverage, lack of lactic acid fermentation flavor, unfavorable for digestion and absorption, and the like, Achieve the effect of improving nutritional value and palatability, scientific and reasonable production process, and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

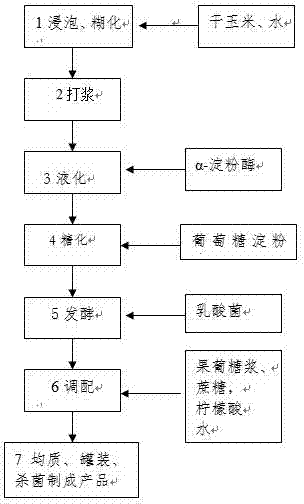

Image

Examples

Embodiment 1

[0024] Embodiment 1: in the production technology of the corn lactic acid fermented beverage of embodiment 1:

[0025] 1) Soaking and gelatinization

[0026] Take 10 kg of dry corn, wash and add 50 kg of water to soak for 8 hours, so that the dry corn kernels absorb water and swell, and the tissue is fully softened; change;

[0027] 2) beating

[0028] Add 20kg of water to the gelatinized corn in step 1, beat for 5 minutes, and then finely grind the obtained slurry in a colloid mill for 3 minutes to make a corn slurry with 50um particles;

[0029] 3) Liquefaction

[0030] Adjust the pH of the finely ground corn steep liquor in step 2) to 6.2-6.4, first add calcium chloride according to 0.2% of the weight of the corn kernels, then add 8 units / g of medium-temperature α-amylase at 83°C to liquefy, and keep warm 15 minutes, when no color is detected with iodine solution, the liquefaction is over, then the temperature is raised to boiling and kept for 5 minutes to inactivate th...

Embodiment 2

[0039] Embodiment 2: in the production technology of the corn lactic acid fermented beverage of embodiment 2:

[0040] 1) Soaking and gelatinization

[0041] Take 10kg of dry corn, wash and add 75 kg of water to soak for 10 hours, so that the dry corn kernels absorb water and swell, and the tissue is fully softened; then fish out, then add 150kg of water to boil the removed expanded corn kernels, and keep for 20 minutes to gelatinize the expanded corn kernels ;

[0042] 2) beating

[0043] Add 35kg of water to the gelatinized corn in step 1, beat for 5 minutes, and then finely grind the obtained slurry in a colloid mill for 4 minutes to make a corn slurry with 75um particles;

[0044] 3) Liquefaction

[0045] Adjust the pH of the corn steep liquor after step 2) to 6.2-6.4, first add calcium chloride according to 0.3% of the weight of the corn kernels, then add 10 units / g of medium-temperature α-amylase at 85°C to liquefy, and keep warm After 18 minutes, check with iodine s...

Embodiment 3

[0054] Embodiment 3: in the production technology of the corn lactic acid fermented beverage of embodiment 3:

[0055] 1) Soaking and gelatinization

[0056] Take 10 kg of dry corn, wash and add 100 kg of water to soak for 12 hours, so that the dry corn kernels absorb water and swell, and the tissue is fully softened; change;

[0057] 2) beating

[0058] Add 50kg of water to the gelatinized corn in step 1, beat for 5 minutes, and then finely grind the obtained slurry in a colloid mill for 5 minutes to make a corn slurry with 100um particles;

[0059] 3) Liquefaction

[0060] Adjust the pH of the corn steep liquor after step 2) to 6.2-6.4, first add calcium chloride according to 0.4% of the weight of the corn kernels, and then add 12 units / g of medium-temperature α-amylase at 87°C to liquefy and keep it warm After 20 minutes, check with iodine solution until there is no color, the liquefaction is over, then raise the temperature to boiling and keep it for 5 minutes to inact...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap