Power head lifting mechanism of gantry movable type numerical-control drilling and milling machine

A lifting mechanism and power head technology, which is applied to metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems of shortened tool life, poor cutting precision, large hanging body of the lifting spindle, etc., to reduce the eccentric moment , Reduce the occupied space, improve the service life and the effect of machine tool machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

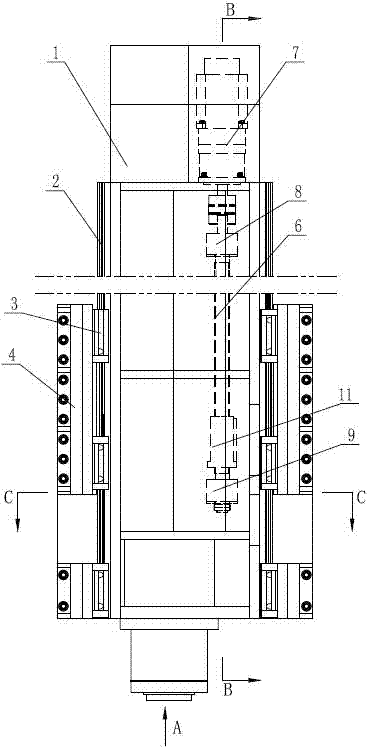

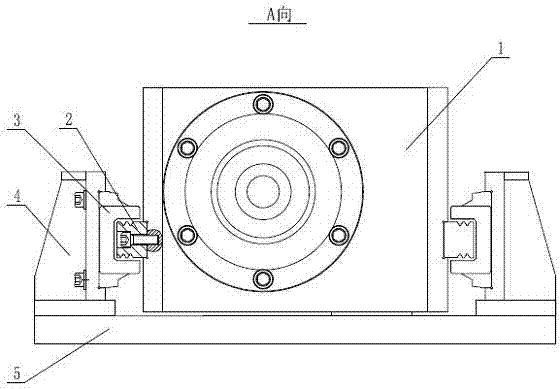

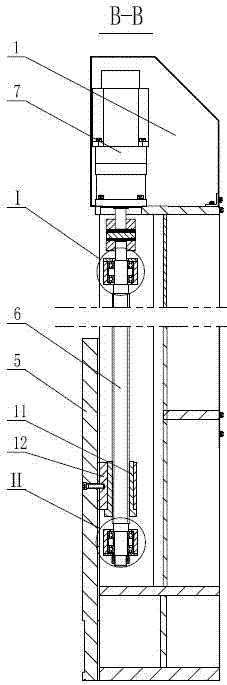

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0019] See figure 1 , figure 2 , image 3 , the present invention includes a power head box body 1, a ball screw pair and a linear guide rail pair, the linear guide rails 2 in the linear guide rail pair are fixedly installed on both sides of the power head box body 1, and the linear guide rails 2 are slidably connected with guide slides block 3, the guide slider 3 is fixedly installed on the installation base 4, the installation base 4 is fixedly installed on the moving plate 5, the linear guide rail 2 and the guide slider 3 constitute the linear guide rail pair; the ball screw pair is mounted on the power In the head box 1, the ball screw 6 in the ball screw pair is connected to the output shaft of the servo motor 7, the axis of the ball screw 6 is parallel to the linear guide rail 2, and the servo motor 7 is fixed in the power head bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com