Headpiece of creasing press for brattice of brattice case

The technology of the enclosure box and the crease machine is applied in the field of the machine head of the crease special processing machine, which can solve the problems of poor production quality, damage to the surface of the plate, and reduction of the strength of the box body, and achieves good crease quality and is not easy to stick to the material. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

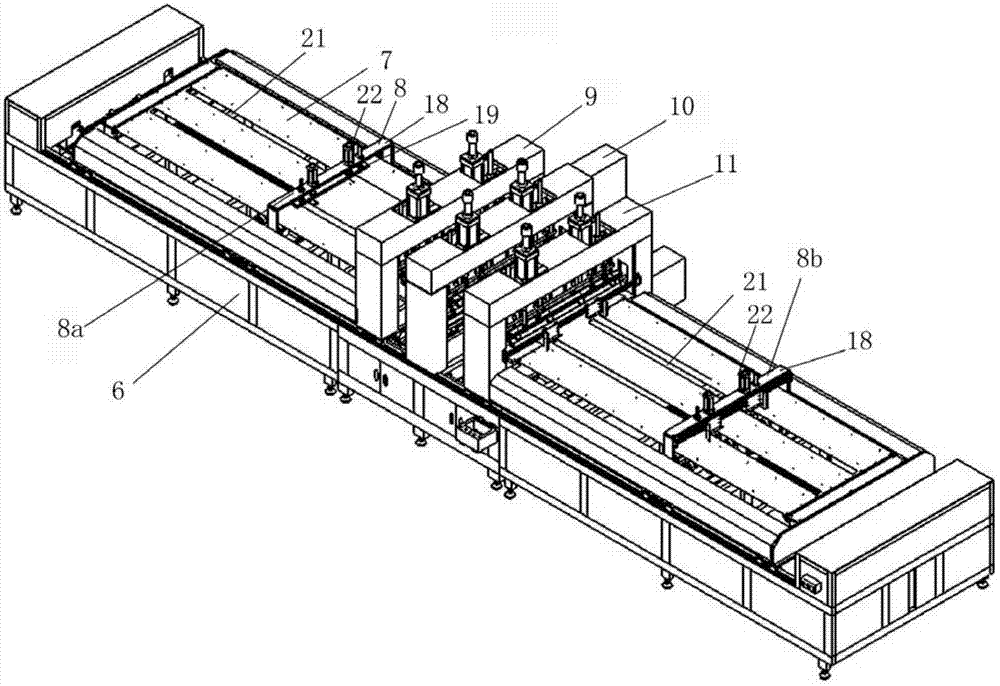

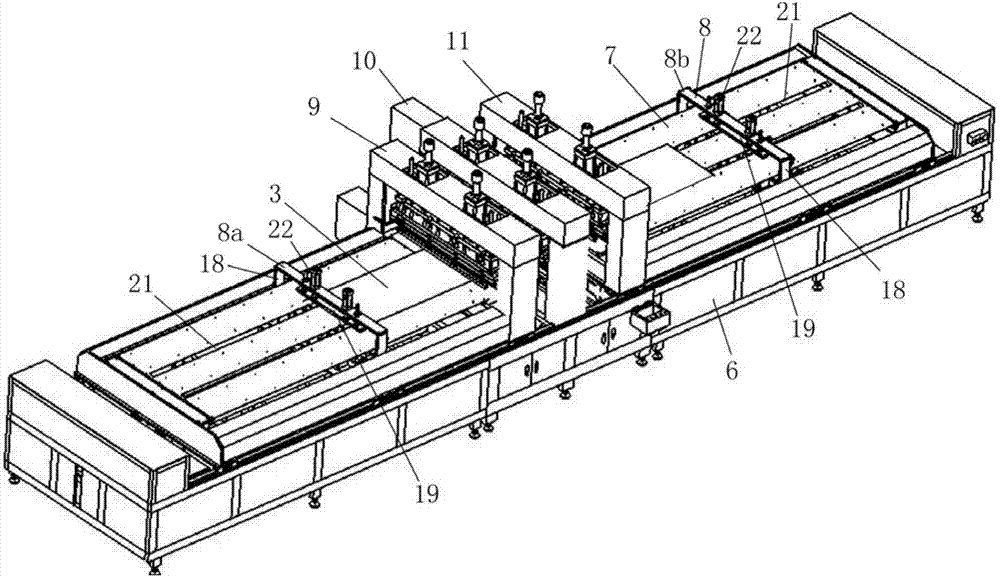

[0028] Example: see Figure 1~Figure 11 Shown:

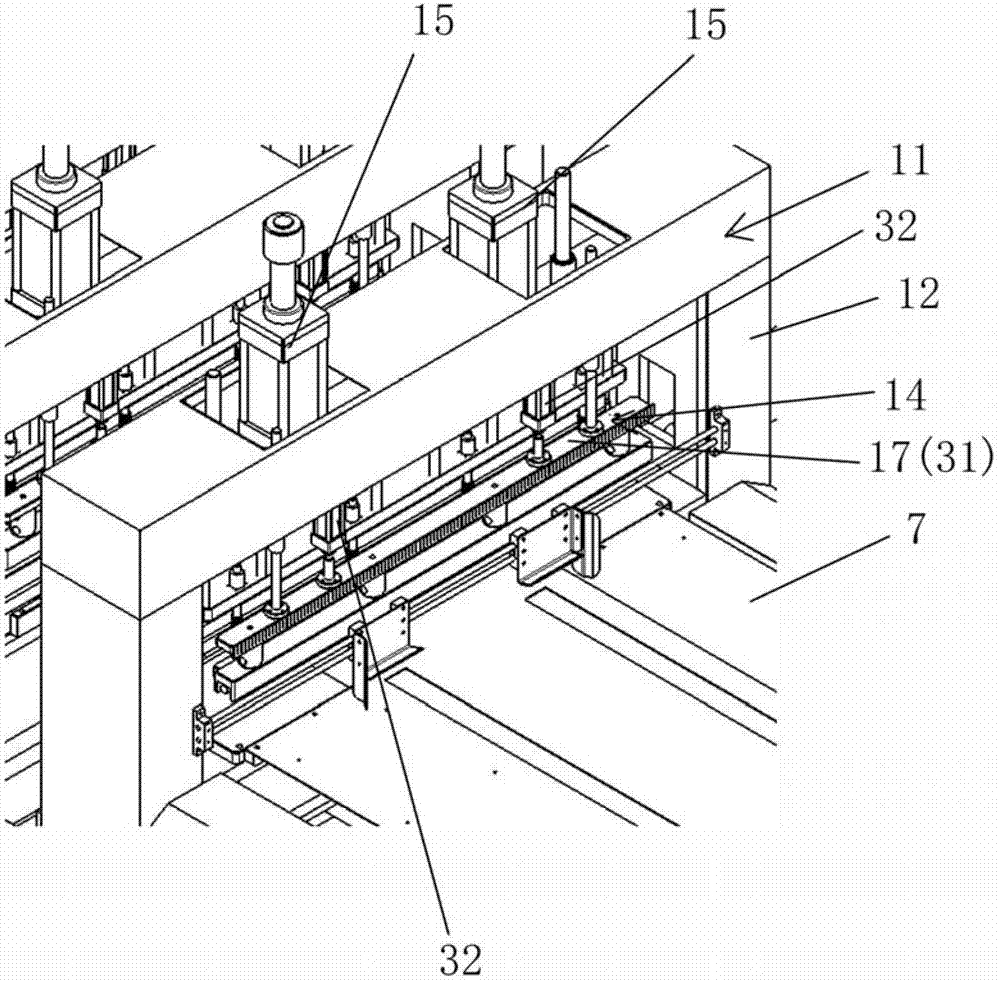

[0029] See Figure 7 , Figure 8 As shown, a coaming box coaming creasing machine head includes a frame body 12 and a heating device 14 and a pressing knife device 13 arranged on the frame body 12. The heating device 14 and the pressing knife device 13 are along the crease The feeding direction of the coaming 3 plates to be processed on the machine table 7 is arranged on the frame body 12 successively, where the heating device 14 is located as a heating station, and where the pressing knife device 13 is located as a molding station. The heating device 14 includes a heating body 17 arranged from top to bottom toward the working table of the creasing machine. The heating body 17 is in the shape of a strip along the width direction of the working table, and the length of the heating body 17 runs through the hoarding 3 to be processed. The width direction of the sheet. Specifically, the heating body 17 can be an electric heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com