Metallurgy coke breeze molding production equipment and system

A production equipment and coke powder technology, which is applied in the field of metallurgical coke powder forming production equipment and systems, can solve the problems of time-consuming and labor-intensive yield, low yield, and low output of metallurgical coke powder forming, and achieve stable operation and improved intelligence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

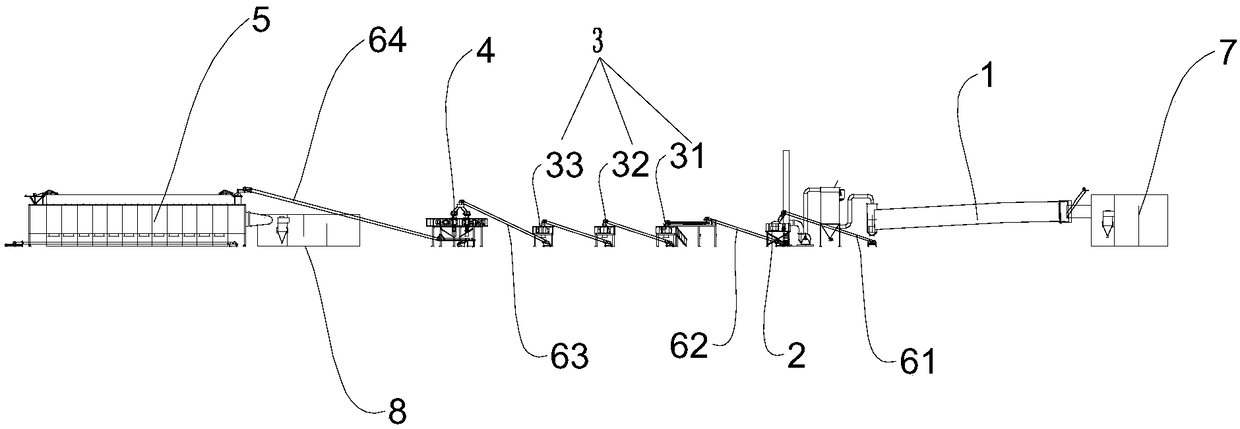

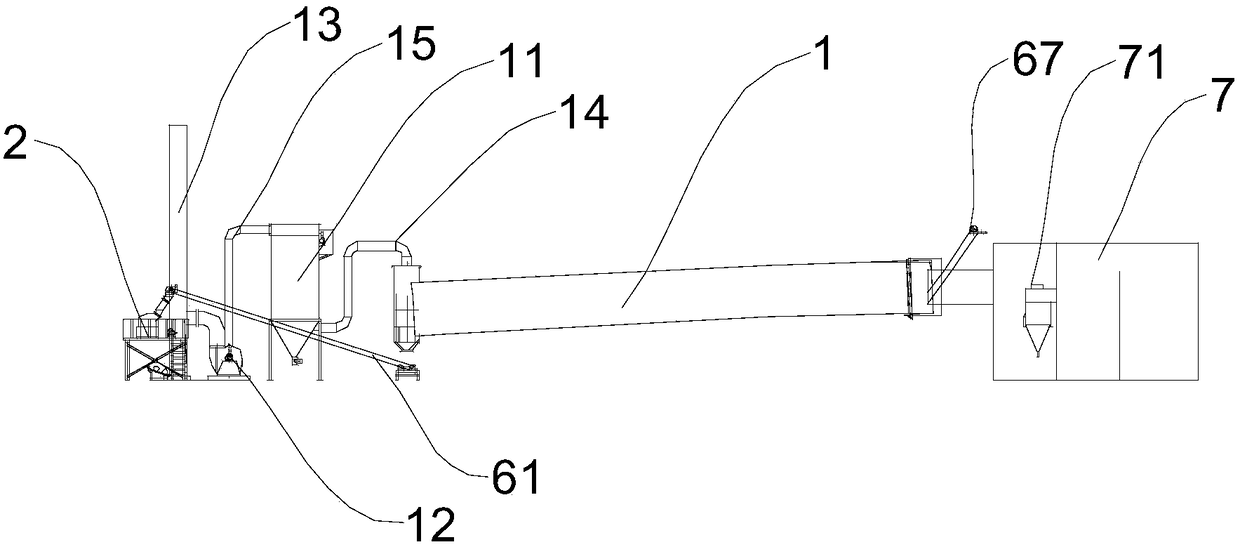

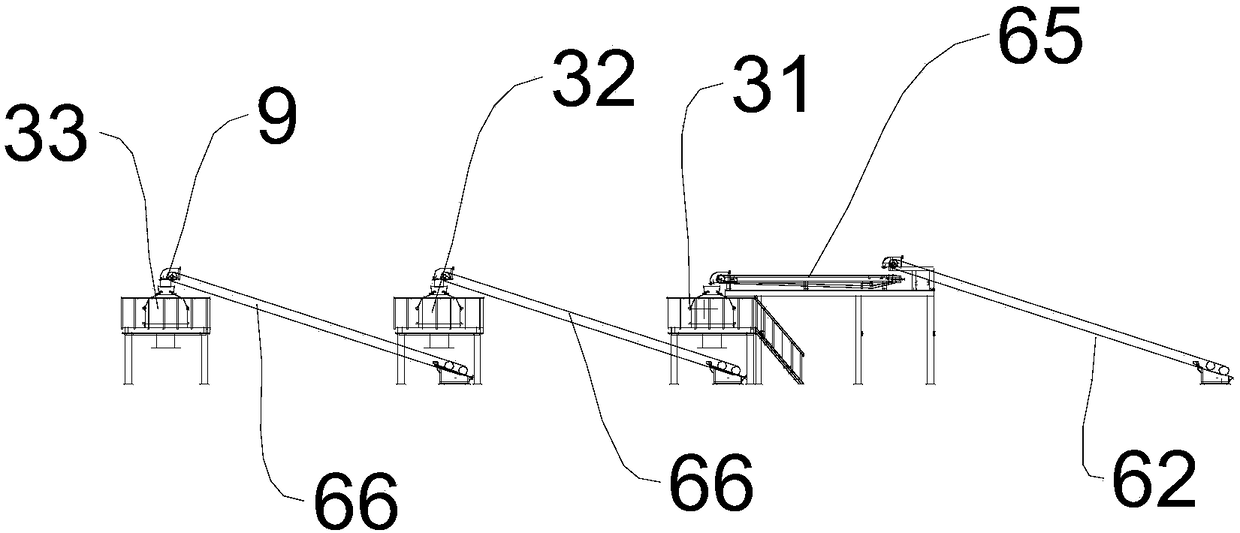

[0043] see Figure 1 to Figure 5 As shown, this embodiment provides a metallurgical coke powder forming production equipment, including a raw material dryer 1, a first conveying assembly 61, a pulverizer 2, a second conveying assembly 62, a mixing and sticking mechanism 3, The third conveying assembly 63 , the finished product pressing mechanism 4 , the fourth conveying assembly 64 and the finished material drying box 5 . Wherein, the raw material dryer 1 is connected with a raw material hot air stove 7 ; the finished product drying box 5 is connected with a finished material hot air stove 8 .

[0044] The pressed finished product mechanism 4 of this embodiment can be composed of several existing conventional ball pressing machines 41, and a common feeding device 42 is arranged above the feeding ports of the several conventional ball pressing machines 41. Raw material hot blast stove 7 and finished product hot blast stove 8 can be the hot blast stove of clean raw material; M...

Embodiment 2

[0065]This embodiment provides a metallurgical coke powder forming production system, including the metallurgical coke powder forming production equipment as described in Embodiment 1 and an intelligent control component that controls the operation of each component of the metallurgical coke powder forming production equipment.

[0066] Described intelligent control assembly is PLC controller, and it and feeding assembly 67, the first conveying assembly 61, the second conveying assembly 62, the 3rd conveying assembly 63, the 4th conveying assembly 64, each mixed sticky conveying assembly The motors of the component 66, the horizontal conveying component 65, and the discharging component 68 are respectively connected to control the conveying speed of each conveying component; at the same time, the PLC controller is also connected with the air volume control equipment of the raw material hot blast stove 7 and the finished product hot blast stove 8 It is used to control the blast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com