Novel creasing machine nose of boarding of boarding box

The technology of a coaming box and a crease machine is applied in the field of the nose of a special crease processing machine, and can solve the problems of poor production quality, reduced box body strength, and inapplicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

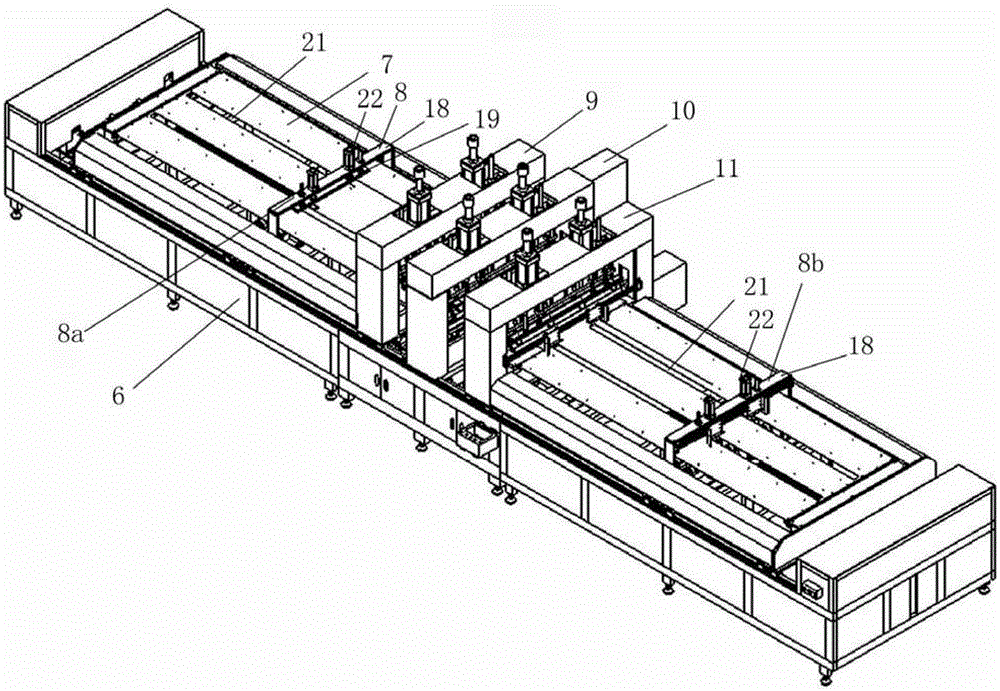

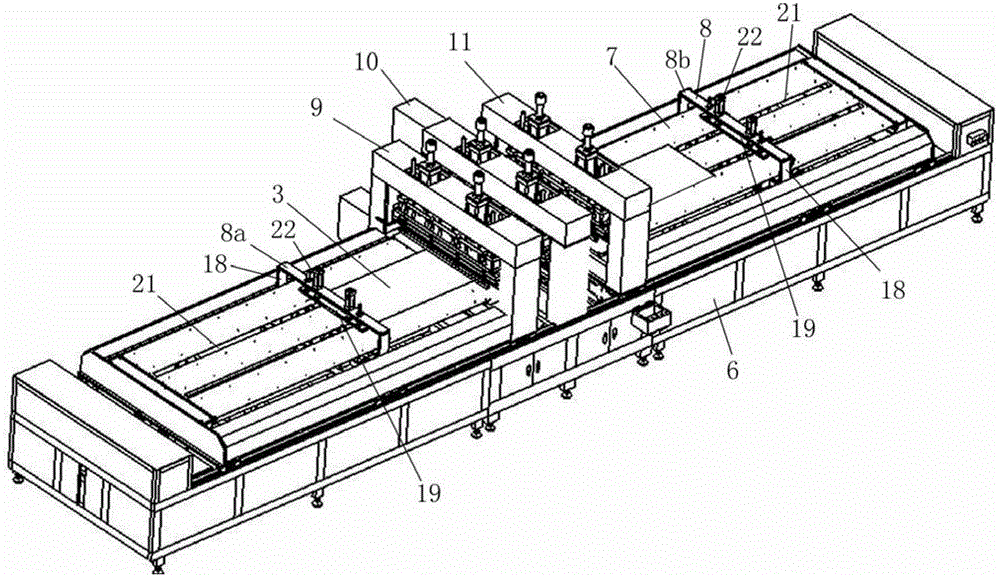

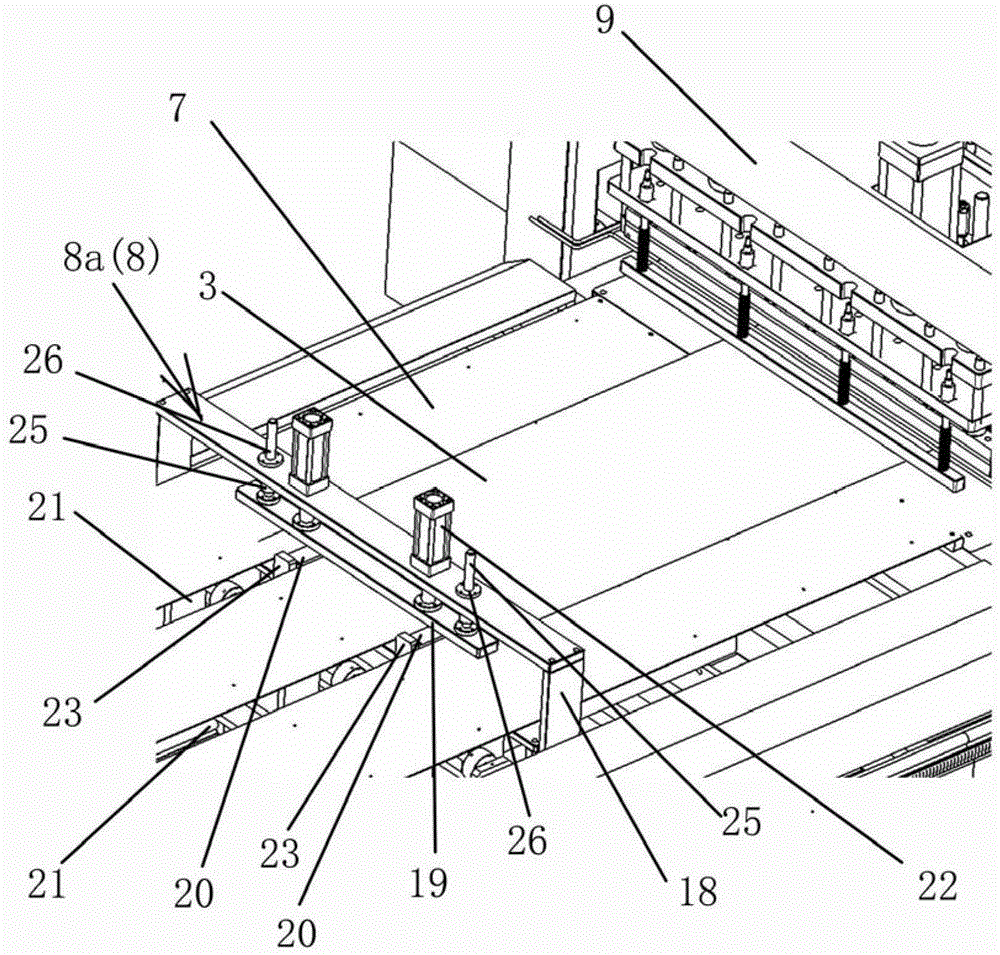

[0038] Embodiment one: see Figure 1~Figure 9 Shown:

[0039] See Figure 5 As shown, a coaming creasing machine head includes a frame body 12 and a crease processing device 13 arranged from top to bottom toward the creasing machine work surface 7; the crease processing device 13 includes a hydraulic cylinder 15 1. A shaft-type processing head 32 connected to the working end of the hydraulic cylinder 15; the shaft-type processing head 32 is slidably connected to the frame body 12 in the up and down direction, and the hydraulic cylinder 15 drives the shaft-type processing head 32 to move up and down.

[0040] See Figure 5As shown, the rotating shaft type processing head 32 includes a rotating shaft 35, a heating device 14, a press tool mold 16 and a rotating drive device. The rotating shaft 35 is arranged along the width direction of the creasing machine worktable 7, and the rotating shaft 35 is opposite to the hydraulic cylinder. 15. The action end is rotatably connected; ...

Embodiment 2

[0048] Embodiment two: see Figure 10 Shown:

[0049] See Figure 10 As shown, a coaming box coaming creasing machine head includes a frame body 12. The difference from Embodiment 1 is that except for the first crease process set from top to bottom toward the creasing machine worktable 7 In addition to the device 13, there is also a second crease processing device 24 arranged from bottom to top toward the working table of the crease machine. The second crease processing device 24 has the same general structure as the first crease processing device 13 , and also includes a hydraulic cylinder 15 and a rotary shaft type processing head 32 connected to the working end of the hydraulic cylinder 15 . Moreover, the shaft-type processing heads 32 of the first crease processing device 13 and the second crease processing device 24 are opposite to each other up and down, and act on the front and back of the workpiece (ie, the panel 3 ) at the same time during operation. In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com