Heat-resistant flame-retardant rubber composition, insulated wire and rubber tube

A technology of flame-retardant rubber and composition, applied in the fields of rubber tube, heat-resistant and flame-retardant rubber composition, and insulated wire, can solve the problems of low cut-through performance, low shape recovery performance and deformation of silicone rubber, and achieve high and low temperature characteristics, Highly balanced mechanical strength, high wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

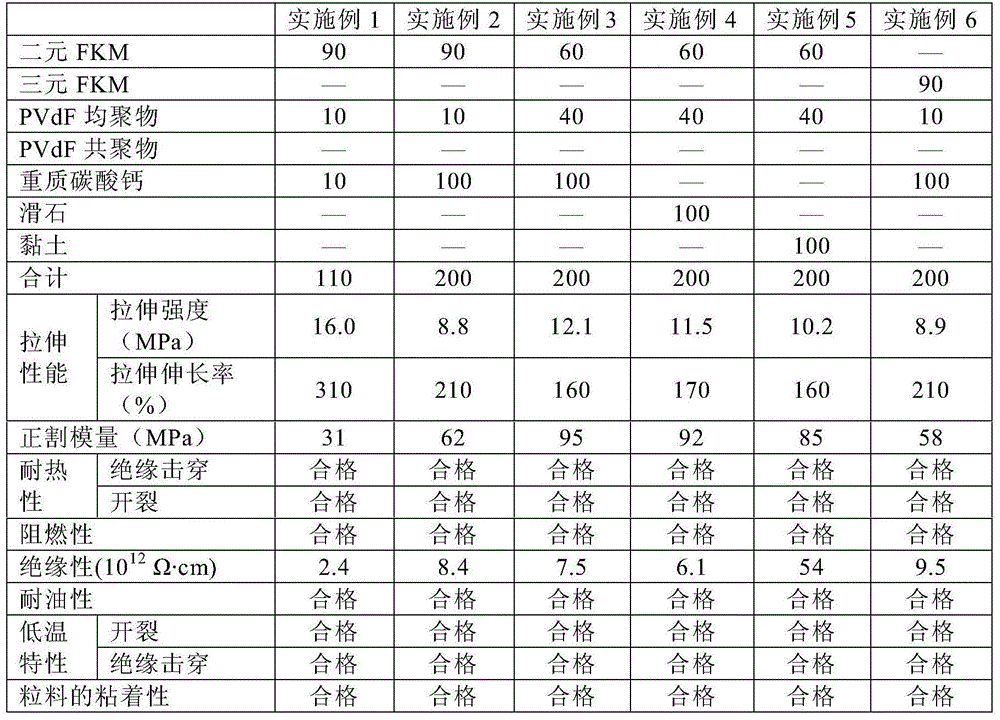

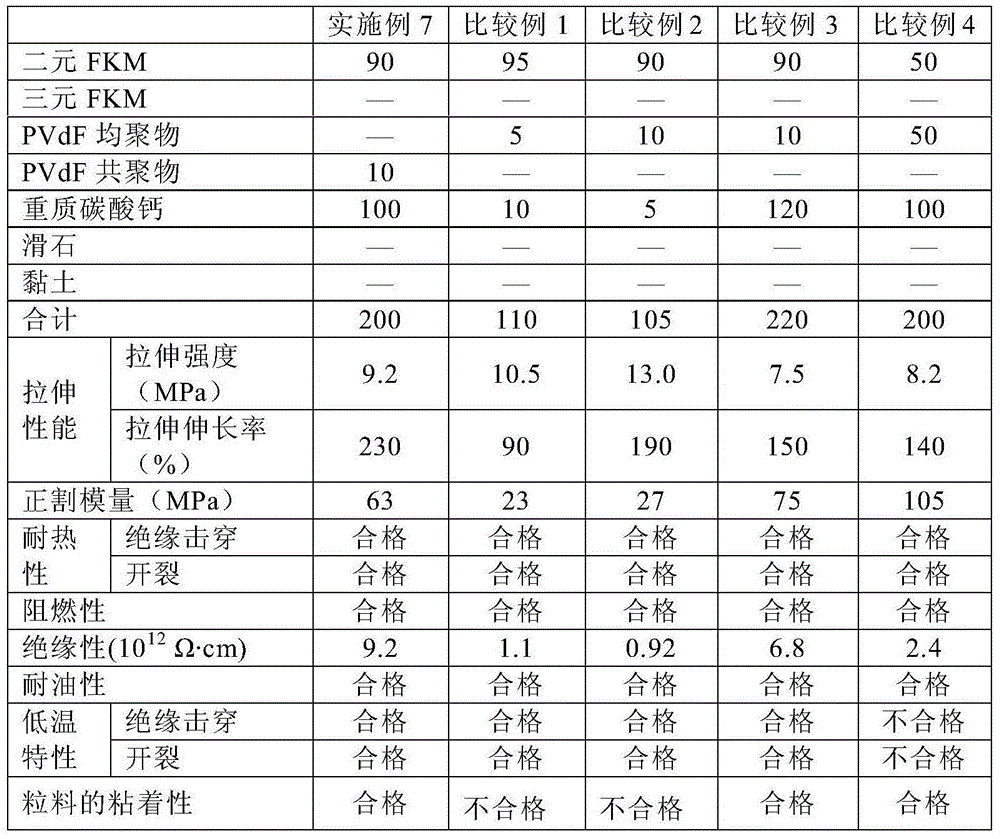

Embodiment 1 to 7 and comparative example 1 to 4

[0052] The ingredients shown in Table I and Table II (expressed in parts by mass in the table) were kneaded with an open mill, and granulated with a granulator. The stickiness of the pellets was evaluated by the following method. The obtained pellets were supplied to an extruder for covering electric wires, which were extruded to a conductor (copper wire; conductor diameter: 0.95 mm) of 0.5 SQ (TA 19 / 0.19) to form a covering having a thickness of 0.375 mm. layer, thereby obtaining a wire with an overall diameter of 1.7 mm.

[0053] Next, an electron beam of 100 kGy was irradiated with an electron beam irradiating apparatus, thereby producing an insulated wire insulatingly covered with a crosslinked rubber composition. The insulated wire (or its insulating coating) obtained in the above manner was evaluated for tensile properties (tensile strength and tensile elongation), flexibility, heat resistance, flame retardancy, insulation, oil resistance by the following methods Evalu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| secant modulus | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com