Patents

Literature

45results about How to "Not prone to sticking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of lithium ion battery high-compaction density pole plate

InactiveCN109473623AIncrease compaction densityLower internal resistanceElectrode rolling/calenderingSecondary cellsInternal resistanceSlurry

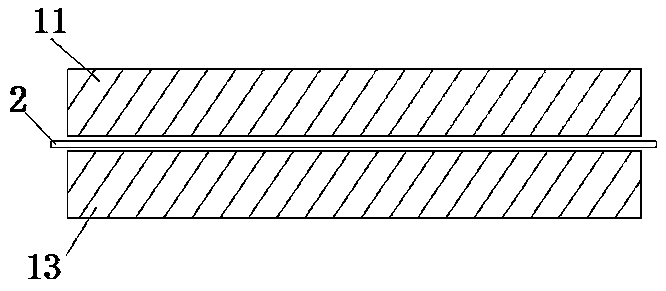

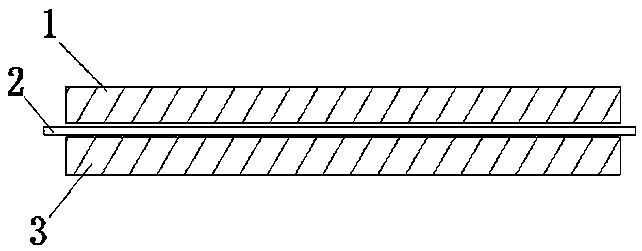

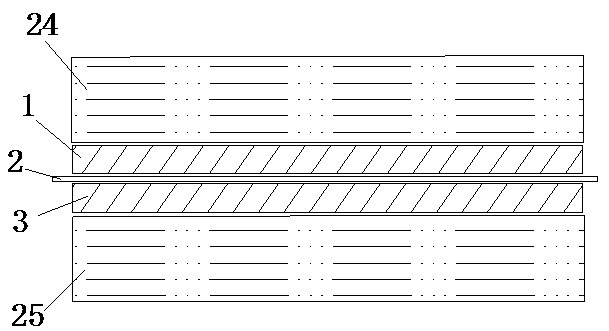

The invention discloses a manufacturing method of a lithium ion battery high-compaction density pole plate. The pole plate comprises a metal current collector and a conducting mixed slurry; the conductive mixed slurry is coated on the metal current collector at twice or multiple times, the pole plate is dried and rolled after the first coating, and the plate is dried and then rolled after the second coating, the coating, the drying, and the rolling are orderly performed until the conducting mixed slurry is completely coated. The thickness of the conducting mixed slurry wet coating layer through twice or multiple coating is thinner than that of once coating process, the drying load is educed, the drying time is shortened, the single rolling load is reduced, the roll coating is hard to occurunder high rolling pressure, the coating uniformity and precision are improved, the compaction density of the pole plate is increased, so that the volumetric specific energy is increased, the internal resistance of the pole plate is reduced, the polarization is reduced, the discharge capacity is increased, the battery energy density is increased, the cost is reduced, the flexibility of the pole plate is guaranteed, and the phenomena that the surface is curly uneven and even the plate is broken or crisp are avoided.

Owner:HUIZHOU WES NEW ENERGY LIMITED

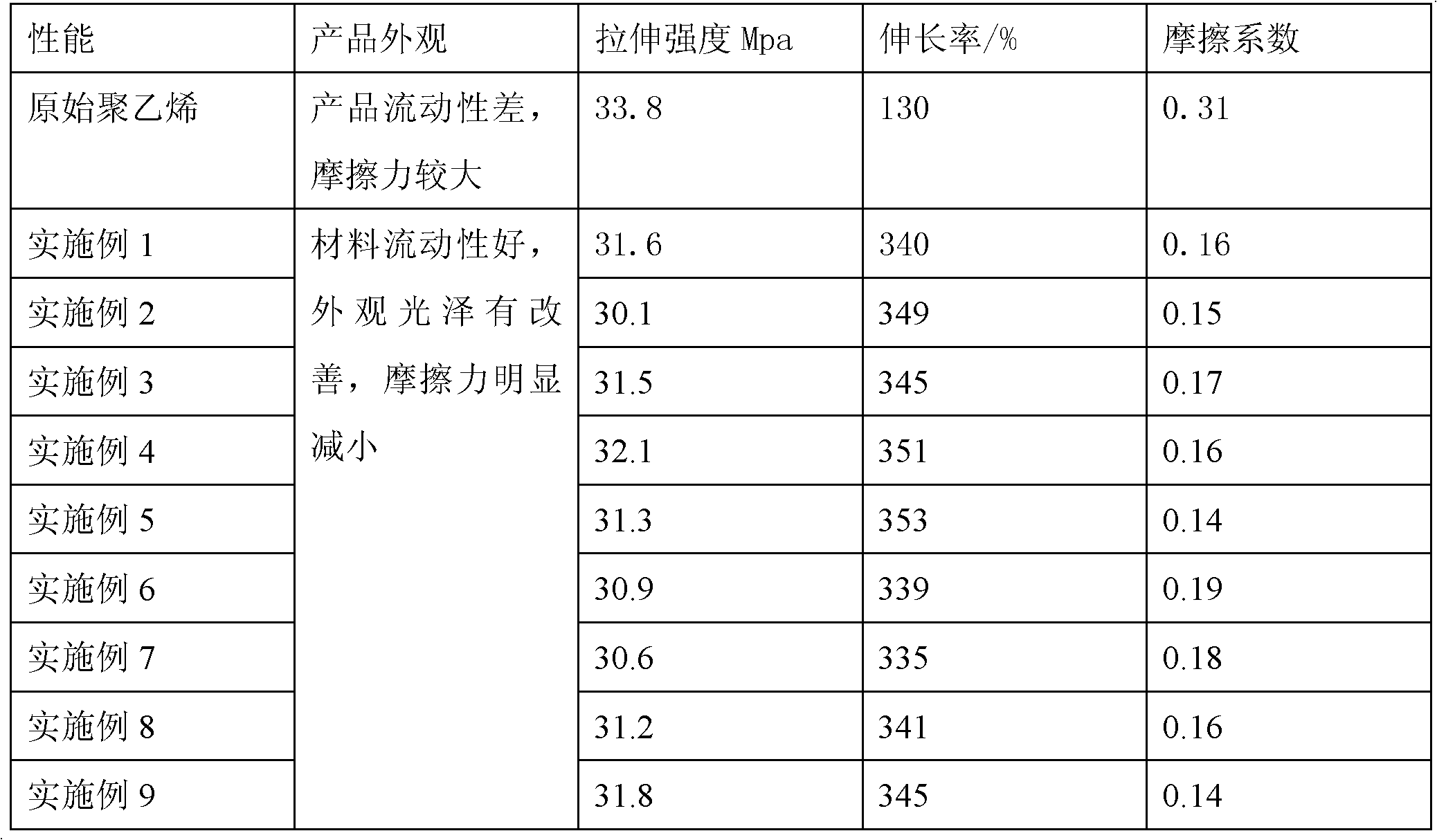

High-density polyethylene material and application thereof

ActiveCN102206374AReduce coefficient of frictionHigh surface glossFibre mechanical structuresAntioxidantPhosphate

The invention relates to a high-density polyethylene material and application thereof. The material comprises the components in percent by weight: 100% of high-density polyethylene, 5-80% of para-phthalic metal salt, 1-8% of silicone oil and 0.5-5% of antioxidant. The para-phthalic metal salt is selected from calcium terephthalate, magnesium terephthalate, zinc terephthalate, potassium terephthalate, sodium terephthalate, barium terephthalate, lead terephthalate, aluminum terephthalate, ferrum terephthalate or a mixture thereof. The silicone oil is selected from active silicone oil, dimethyl silicone oil, 201 methyl silicone oil or a mixture thereof. The antioxidant is selected from tris(2,4-ditert-butylphenyl) phosphate, pentaerythrite tetra [beta-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate], 2,6-di-tert-butyl-4-methylphenol, 2,2'-methylenebis[6-(1,1-dimethylethyl)-4-methyl-phenol or a mixture thereof. The polyethylene material provided by the invention has a small friction coefficient and favorable self-lubricity and can be used for manufacturing optical cable protection sleeves.

Owner:江苏爱特恩高分子材料有限公司

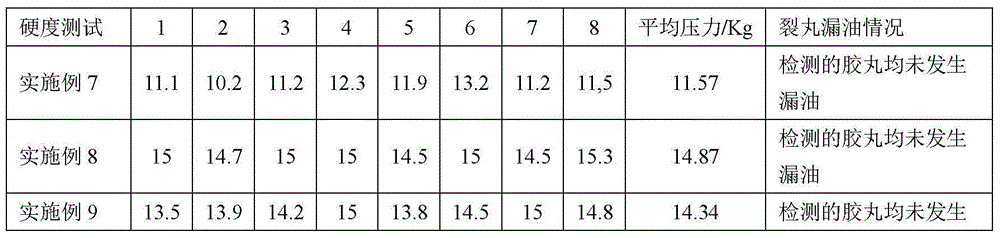

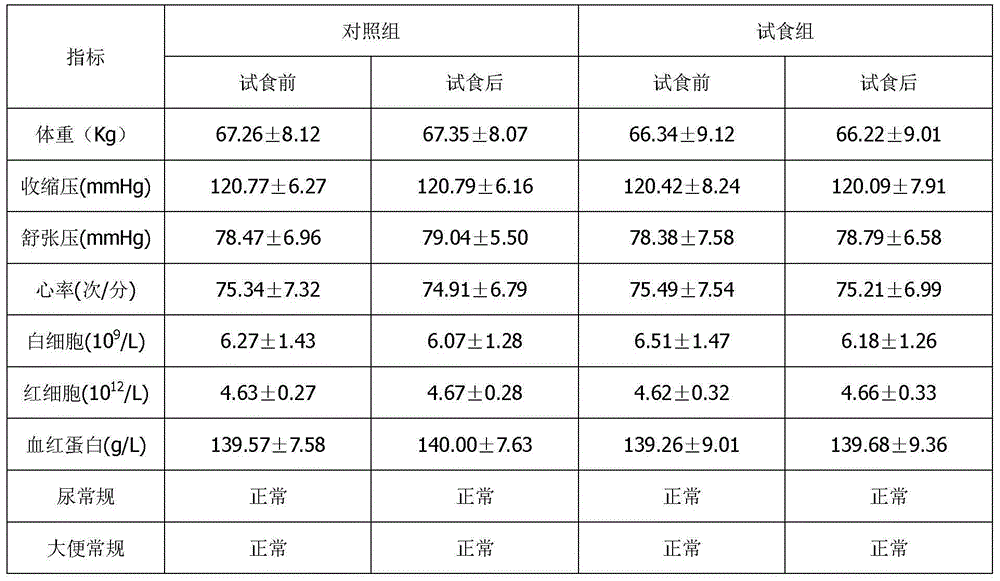

Soft capsules and production method thereof

InactiveCN104523815AAppropriate hardnessNot easy for capsules to stickCapsule deliveryGranular deliverySOYBEAN SEED OILGlycerol

The invention discloses soft capsules and a production method thereof. Contents of the soft capsules consist of an astragalus membranaceus extract, a ginkgo leaf extract, soybean oil and bee wax; capsule skins of the soft capsules consist of gelatin, glycerin, water, titanium dioxide and cacao husk pigments; and capsule shells of the soft capsules are appropriate in hardness, cannot be too hard, and also cannot be relatively soft. The soft capsules disclosed by the invention are not easy to cause capsule bonding in storage and transportation processes; the bee wax is taken as a suspension-assisted stabilizing agent, and after the bee wax is added, two traditional Chinese medicine extracts namely the astragalus membranaceus extract and the ginkgo leaf extract can be uniformly suspended into the soybean oil, so that the stability of the contents can be improved, and the occurrence of layering phenomena can be prevented. By virtue of polishing treatment performed by a colloid grinder, particle sizes of two traditional Chinese medicine extract particles namely astragalus membranaceus extract particles and ginkgo leaf extract particles can become smaller, so that the problems of discharging pipe blockage, incomplete filling, low pelleting production efficiency and the like caused in a pelleting process can be solved. The capsules produced by using the method disclosed by the invention are not easy to cause oil leakage, are suitable for pelleting, and are high in production efficiency.

Owner:NANNING FRESH LIFE BIOTECH

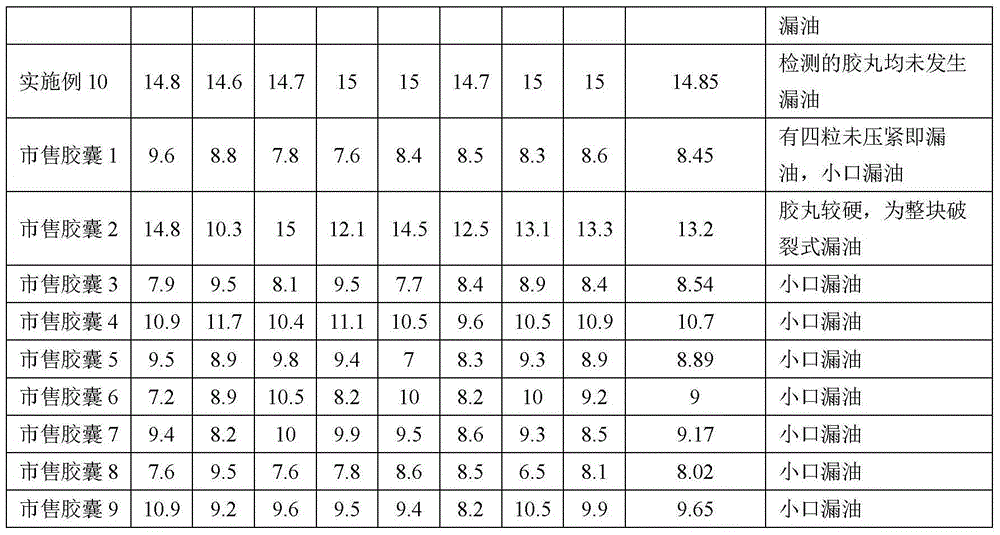

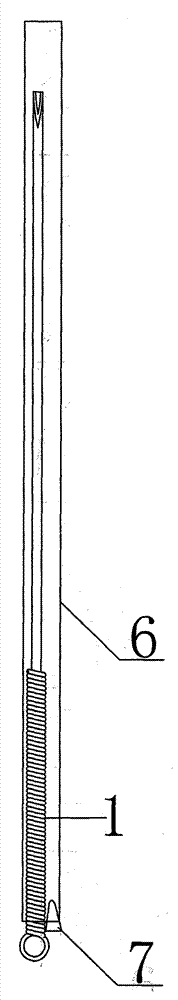

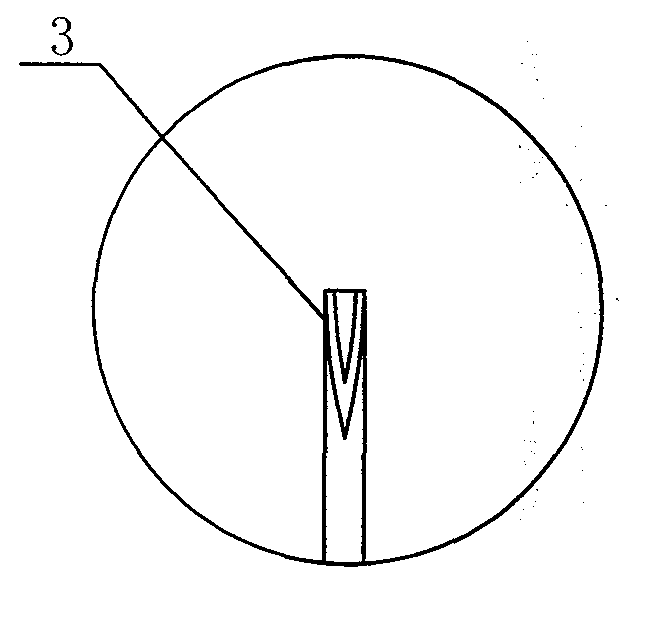

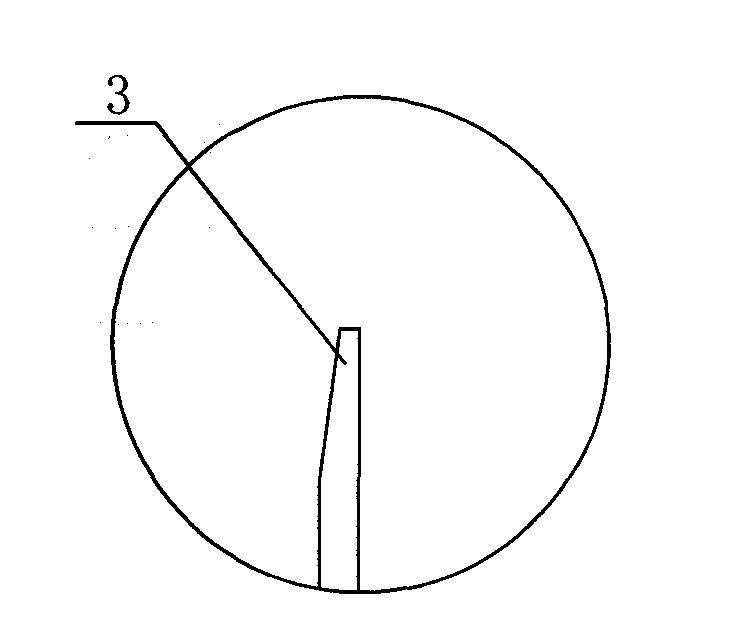

Arc-shaped-edge needle knife

ActiveCN102961174AEasier and faster repair of adhesionsNot easy to stickIncision instrumentsInjections needleTissue damage

The invention relates to the field of medical apparatuses, in particular to an arc-shaped-edge needle knife for medical treatment, face beautification and health care. The arc-shaped-edge needle knife comprises a needle handle, a hollow needle body which is connected with the needle handle, and a knife head which is arranged at the end part of the needle body. The knife head is an inclined surface and is intersected with a plane of a circular-arc-shaped edge which is arranged at the top end. An included angle between the intersection line and the needle body is within 30-150 degrees. Compared with the prior art, the arc-shaped-edge needle knife has the advantages that: 1) the functions of an injection needle and an interventional operation guide casing needle can be realized; 2) compared with the traditional needle knife with an in-line edge, tissues can be rapidly repaired more easily and are not apt to adhere and scar; 3) the maximum release effect can be achieved on the premise of minimum tissue invasion; and 4) due to the characteristic of the arc-shaped edge, the cross-shaped cutting, the Union-Jack-shaped cutting and the like of the traditional needle knife are thoroughly simplified to be in-line cutting, the tissue damages, the pains of patients and the treatment time of doctors are reduced, the operation is simple just like intramuscular injection, and a thorough needle knife revolution is aroused.

Owner:王学昌

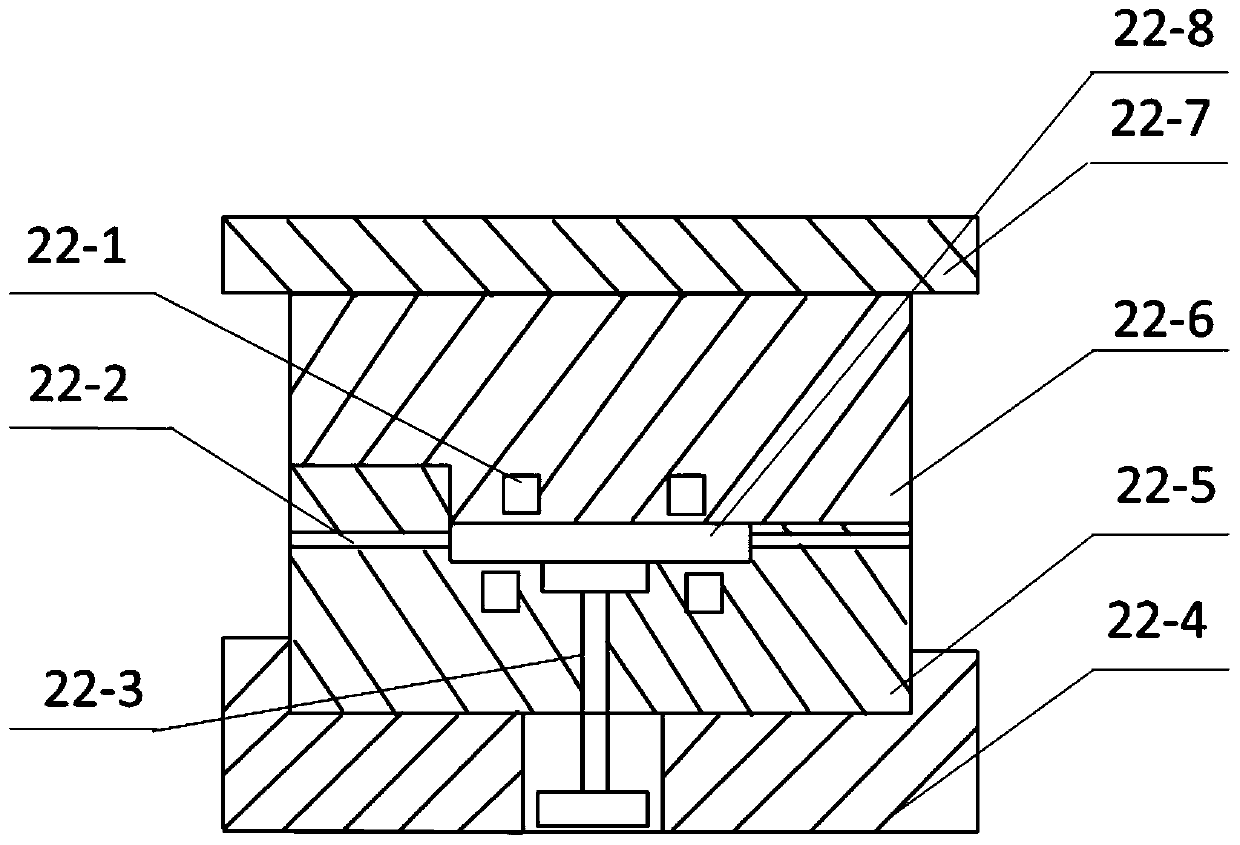

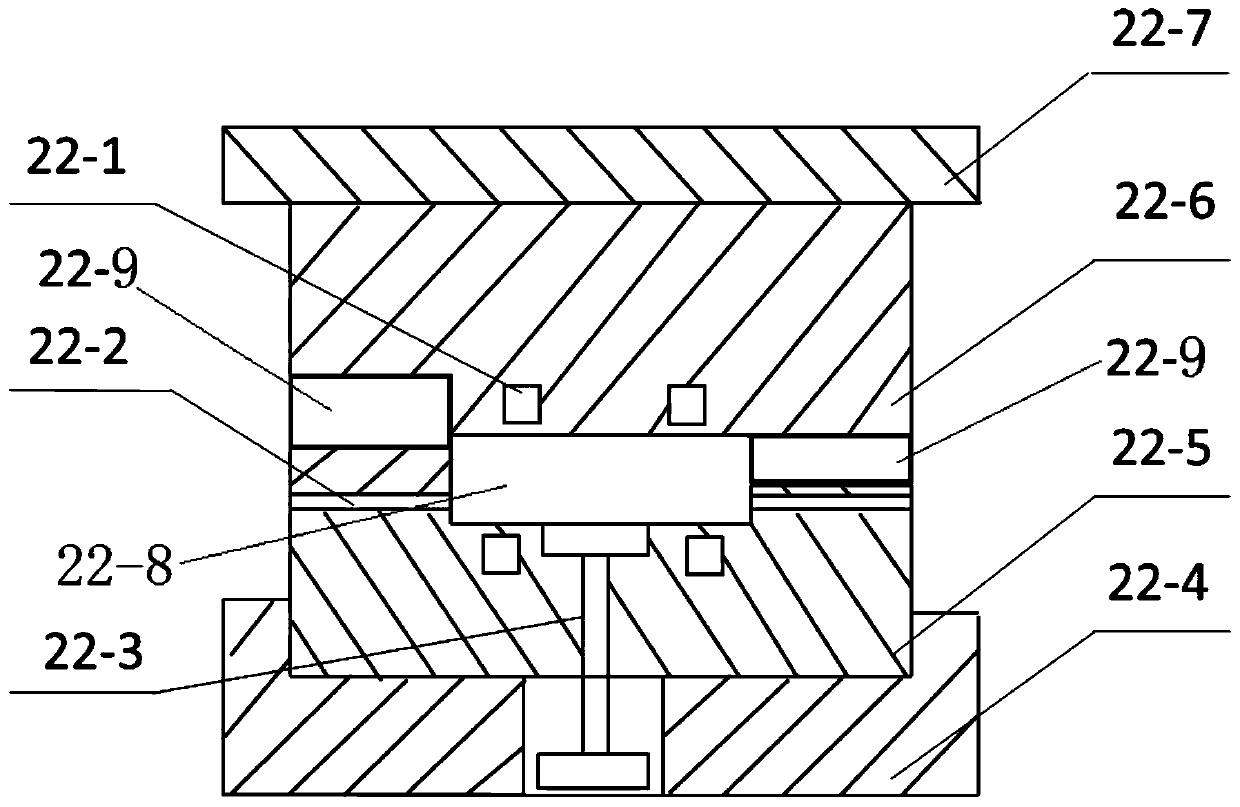

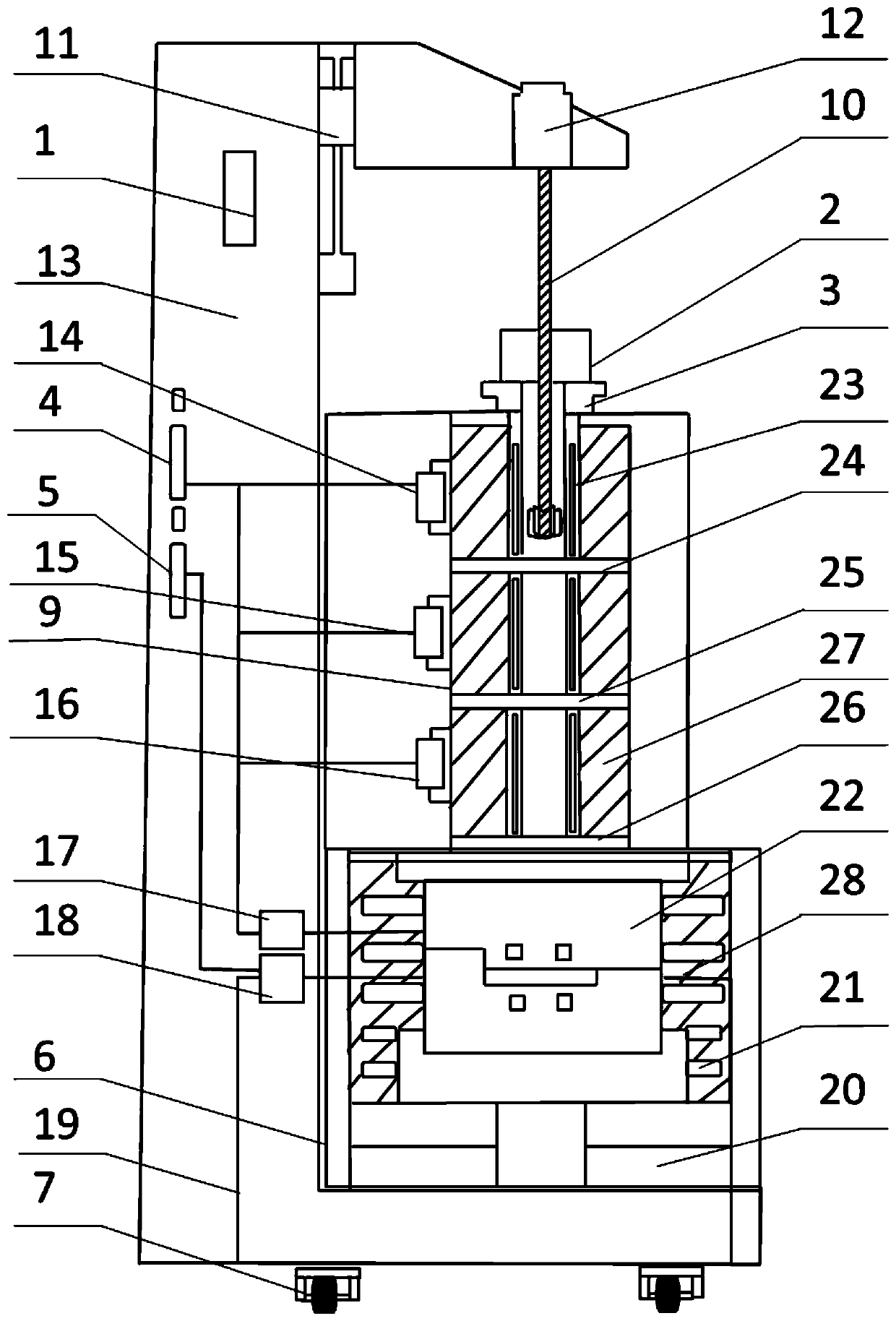

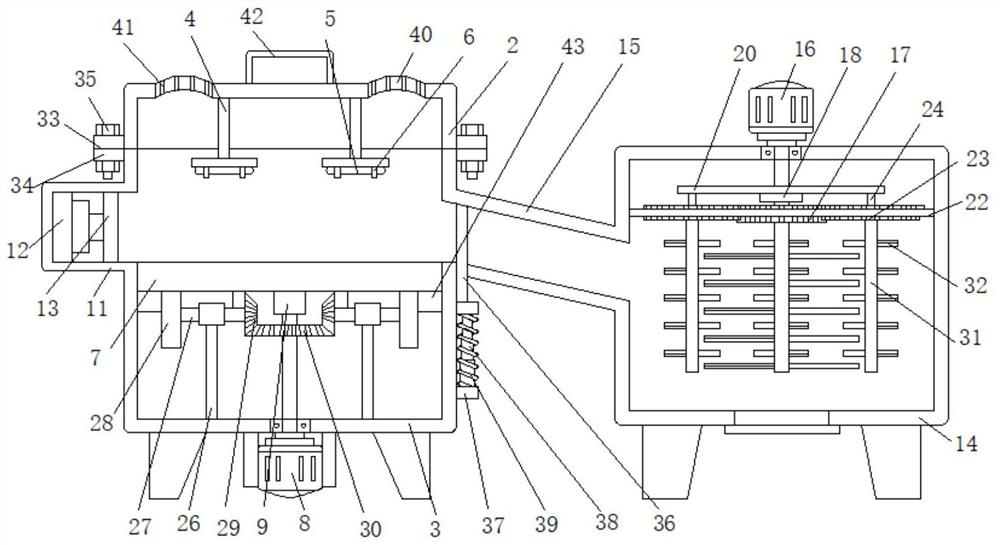

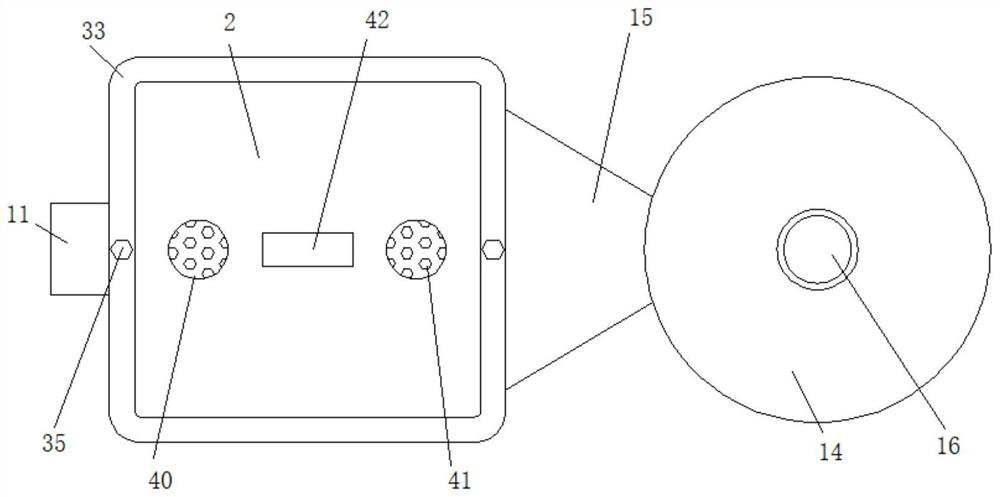

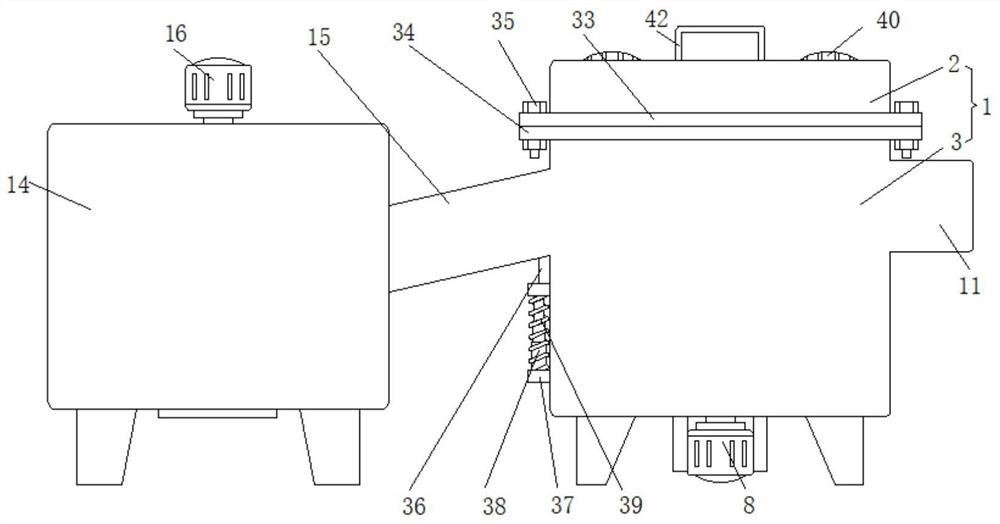

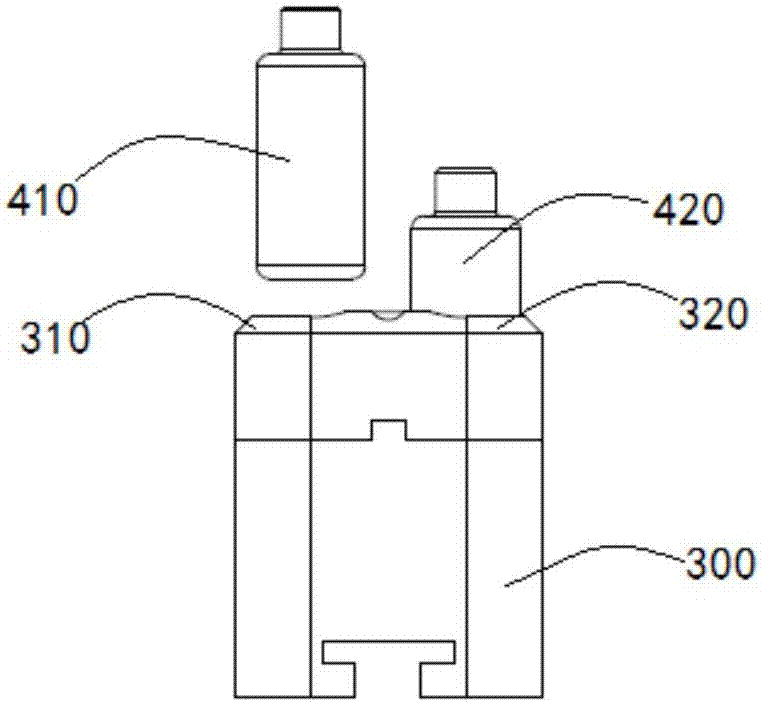

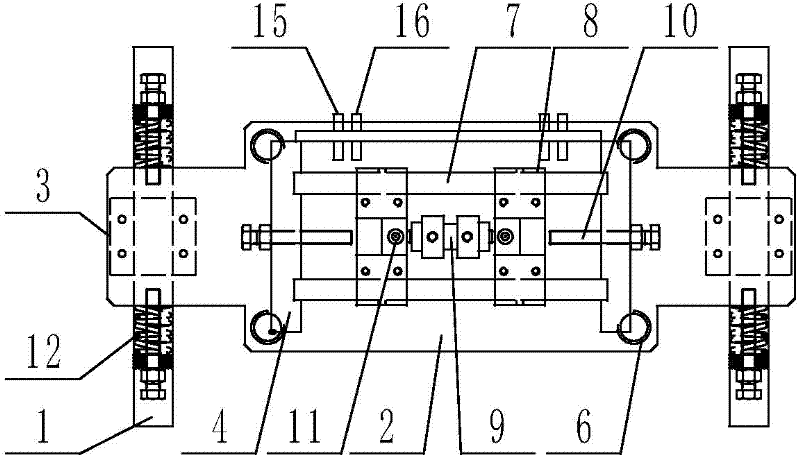

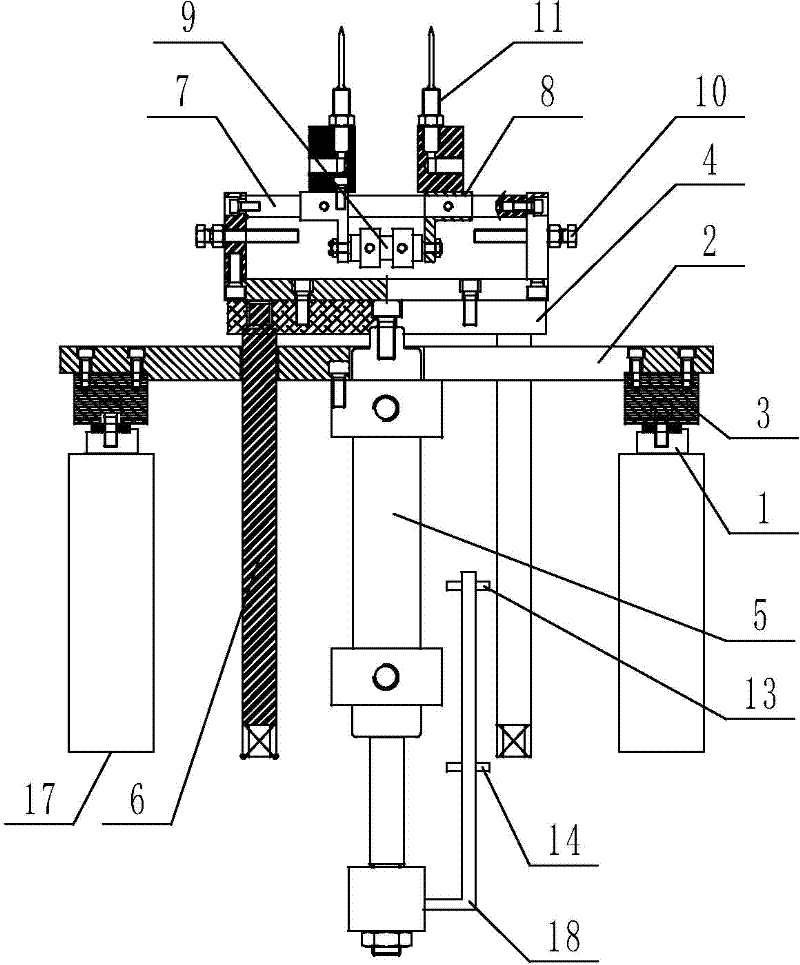

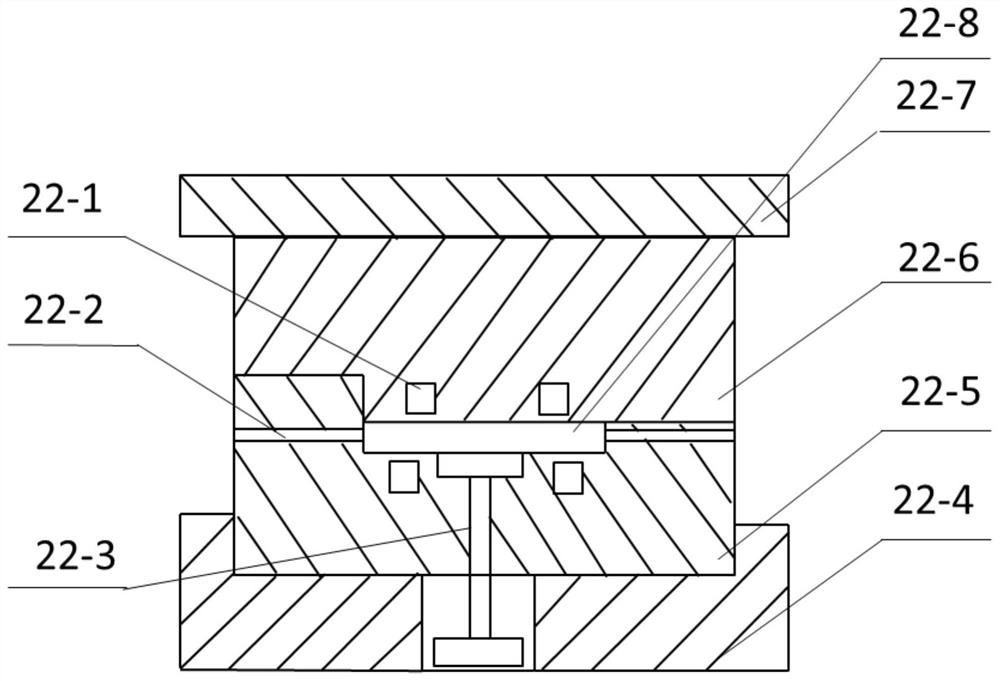

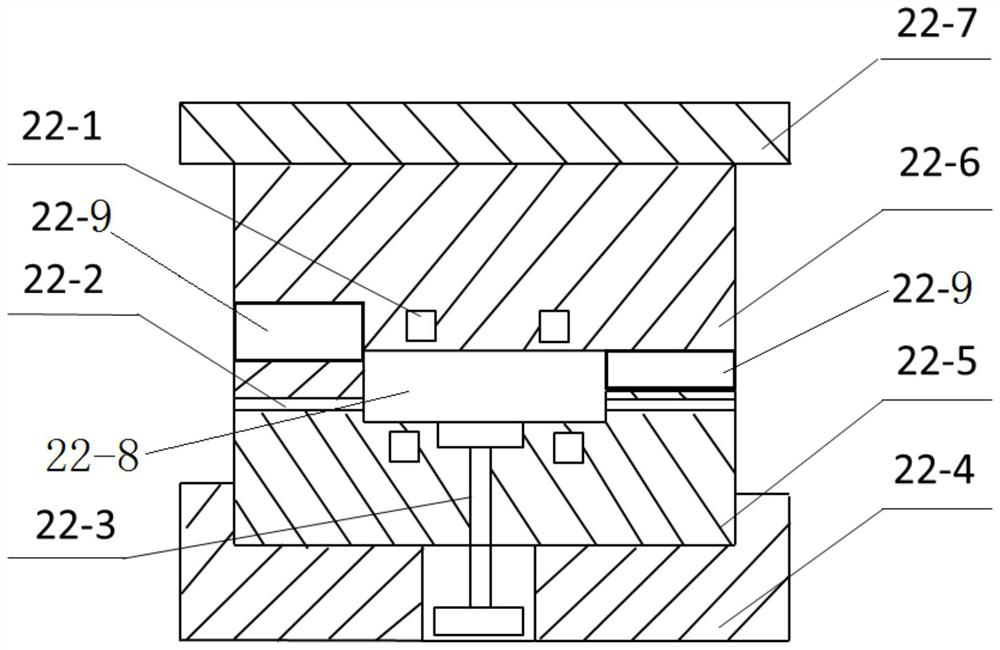

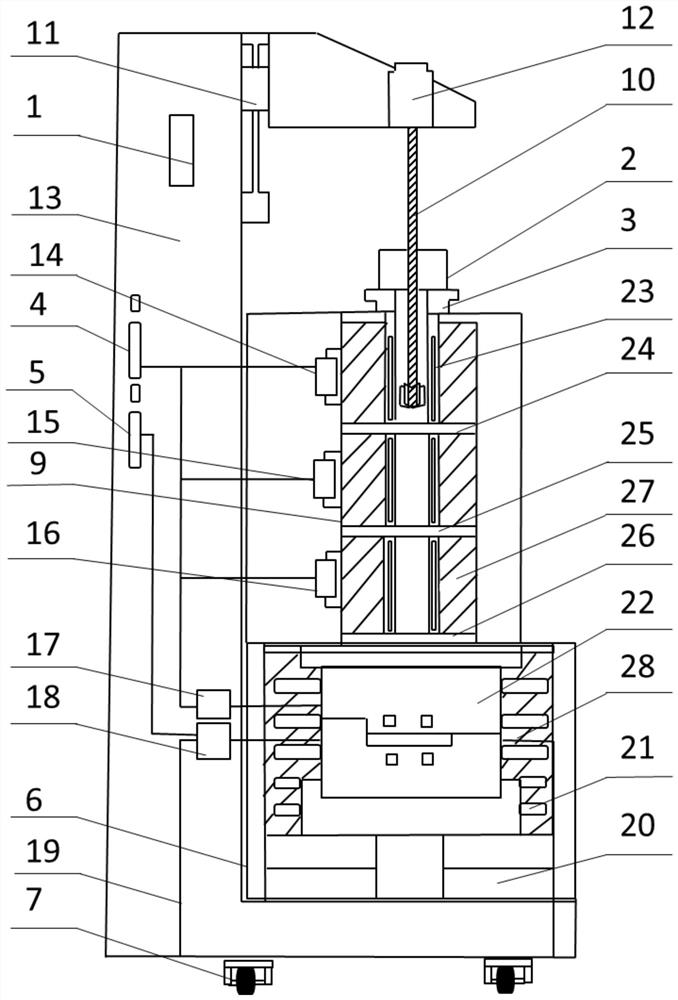

Mold and production device for preparing foam sandwich panel

ActiveCN110042268AGood interfacial metallurgical bondingSmall coefficient of thermal expansionTube furnaceResistance wire

The invention discloses a mold and production device for preparing a foam sandwich panel. The mold comprises an ejection rod, a concave mold fixing plate, a concave mold, a convex mold and a convex mold fixing plate. The production device comprises a box furnace, a tube furnace, a stirring paddle, a stirring paddle lifting device, a speed adjustable motor, a first temperature zone temperature regulator, a second temperature zone temperature regulator, a third temperature zone temperature regulator, a box furnace temperature regulator, a cooled material flow rate regulator, a mold lifting device, a resistance wire, the mold, a first temperature zone baffle, a second temperature zone baffle and a third temperature zone baffle. One-time forming of the closed-cell foam metal sandwich panel isachieved by controlling the surface temperature and the internal temperature of melt on the basis of a melt foaming method; and production of sandwich panels with the same thickness and different foamlayer thicknesses is achieved by adjusting the cooled material flow rate, and production of sandwich panels of different thicknesses is achieved by adjusting the thickness of a gasket between the convex mold and the concave mold.

Owner:HEBEI UNIV OF TECH

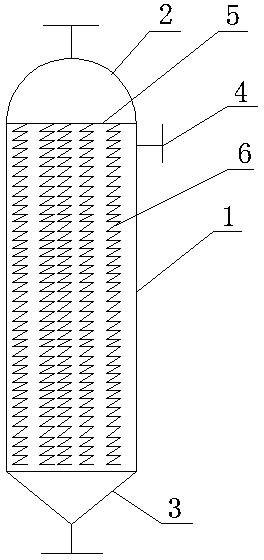

Crystal catcher applied to acid anhydrides

ActiveCN104208900ANot prone to stickingHigh yieldCrystallization separationWastewaterUltimate tensile strength

The invention discloses a crystal catcher applied to acid anhydrides, relating to the technical field of production of 1,2,4,5-benzenetetracarboxylic anhydride and other acid anhydrides, and in particular relates to a crystal collection device. The crystal catcher applied to acid anhydrides comprises a cylindrical shell, wherein the upper end of the shell is connected with an upper spherical sealing head in a sealing manner; the lower end of the shell is connected with a lower conical sealing head in the sealing manner; the crystal catcher is characterized in that a plurality of springs are uniformly distributed in the shell; the upper ends of the springs are respectively connected with the upper end of the shell; the lower ends of the springs are free ends. As the springs can freely swing in the shell, the heat exchange area can be increased, and the materials attached to the springs can fall off at any time and are unlikely to stick to the springs. The crystal catcher applied to acid anhydrides has the advantages that the energy consumption is low, the loss is low, the material yield is high, the material blockage is avoided, the operation is continuous, the labor intensity is low, the crystal catcher does not need to be cleaned by washing and the waste water is not produced.

Owner:JIANGSU HUALUN CHEM

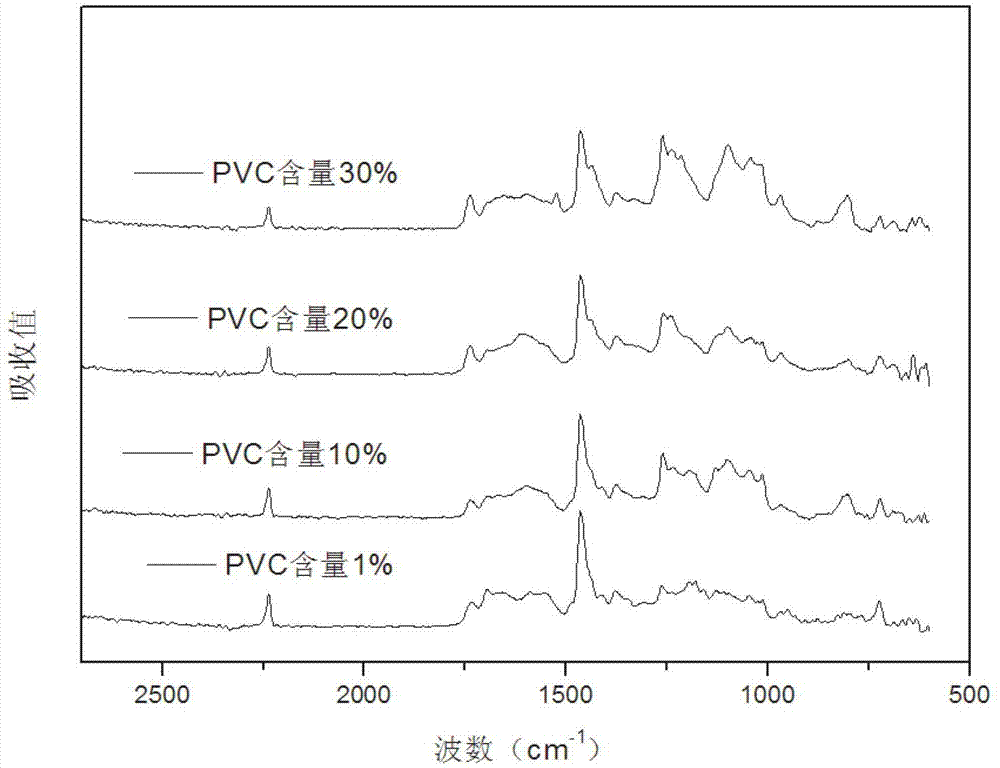

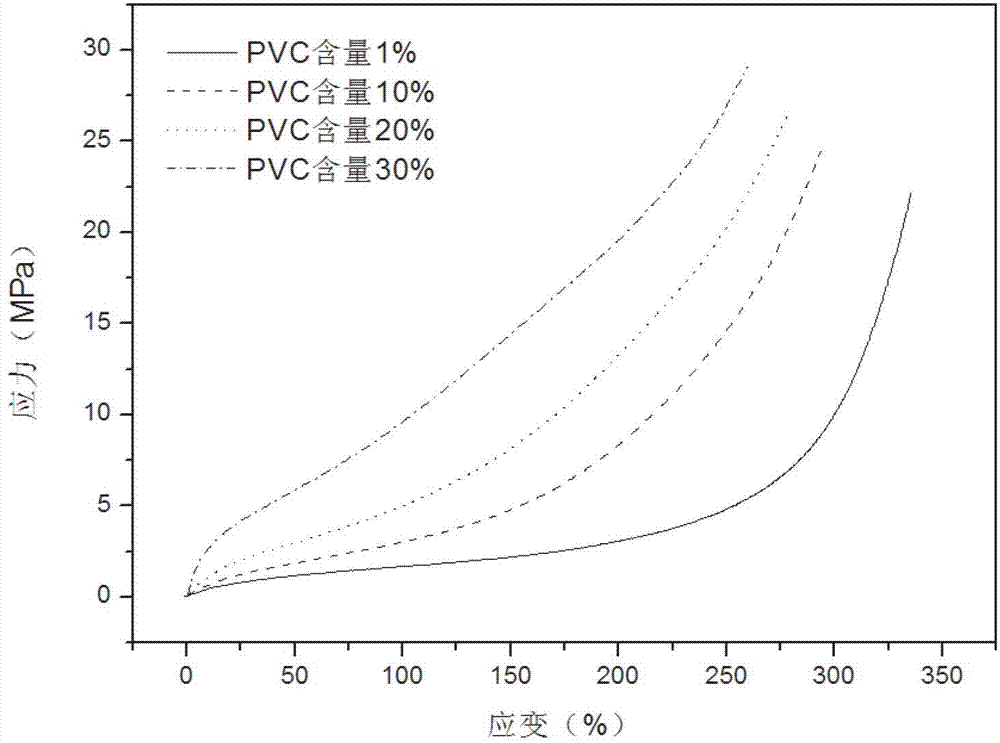

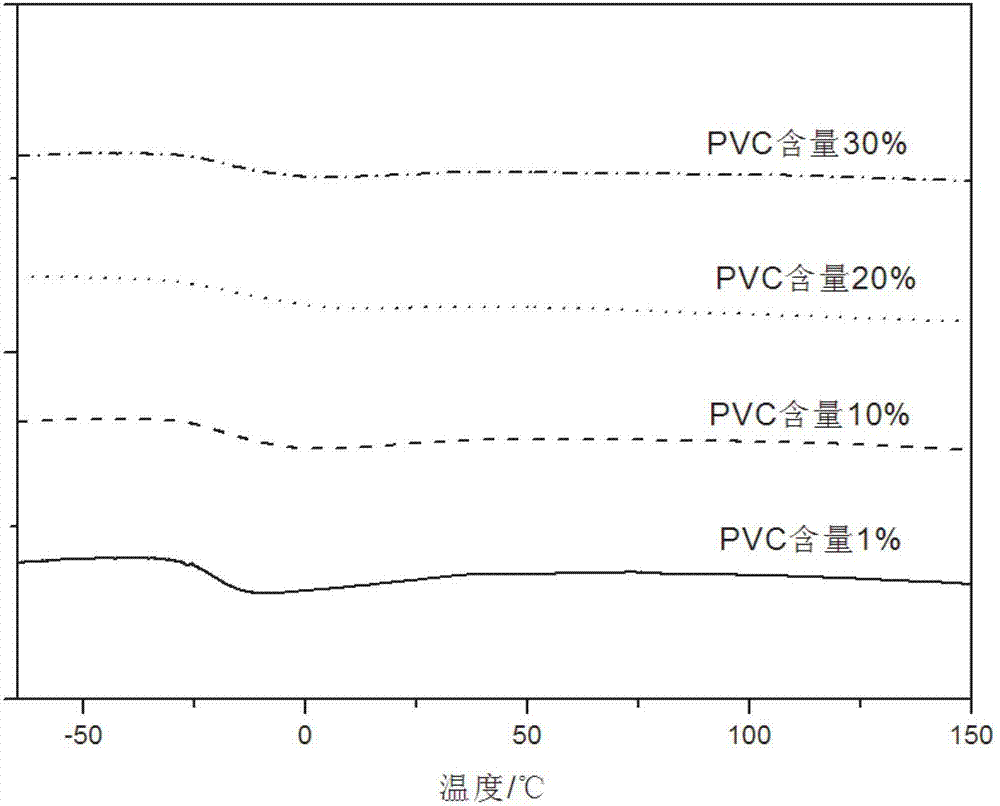

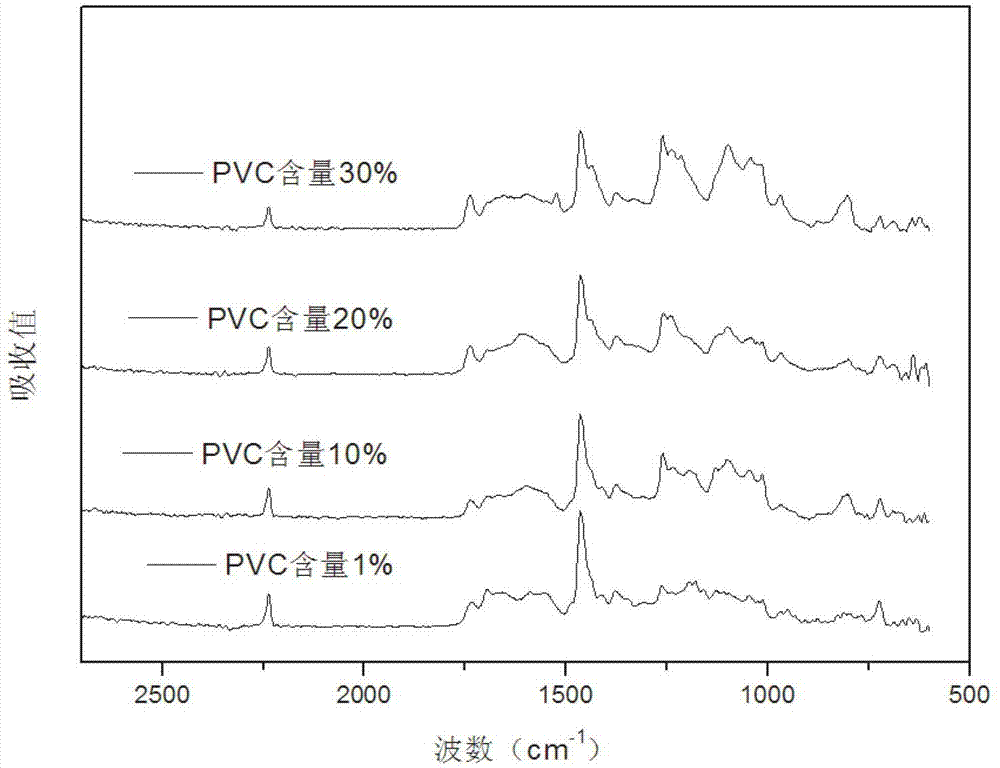

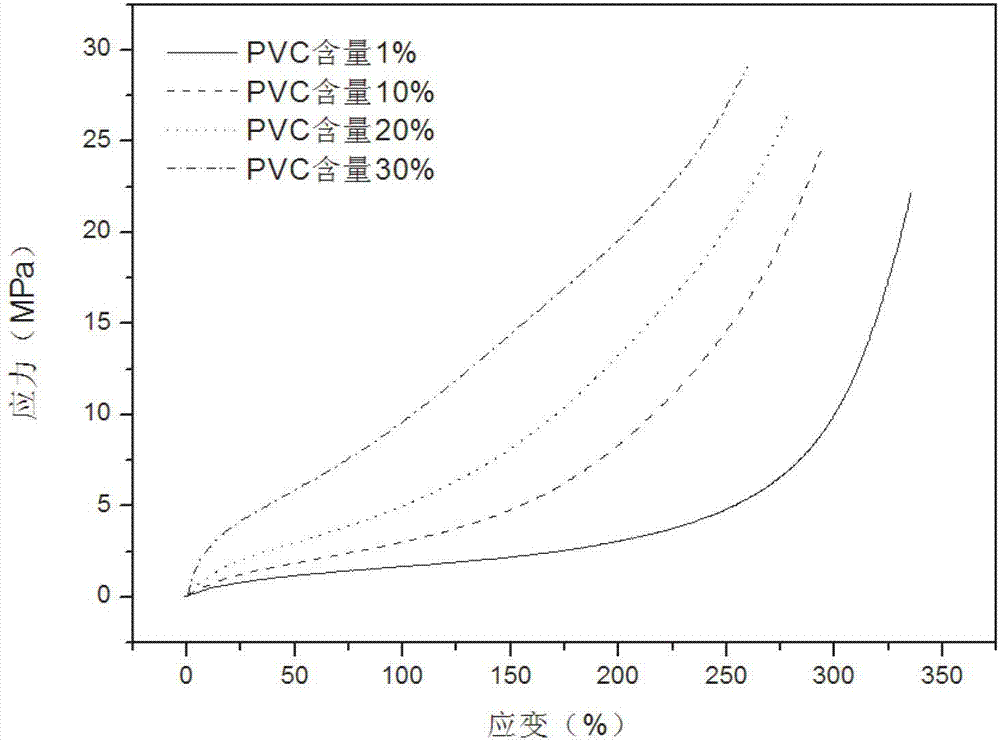

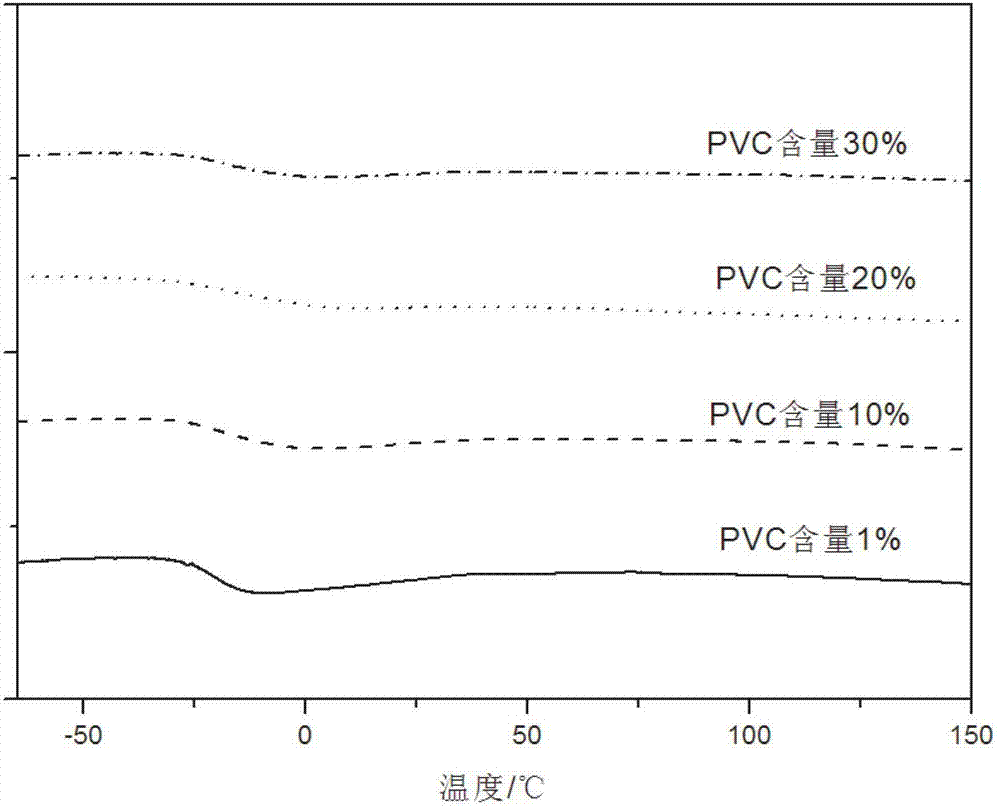

Non-vulcanized glue film of hydrogenated butyronitrile-polyvinyl chloride blended emulsion and preparation and application thereof

The invention discloses a non-vulcanized glue film of a hydrogenated butyronitrile-polyvinyl chloride blended emulsion and a preparation method and an application thereof, which belong to a chemical product and a preparation method thereof. The method is characterized in that: a non-vulcanized self-crosslinking HNBR (Hydrogenated Nitrile Butadiene Rubber) / PVC (Polyvinyl Chloride) latex film is prepared from HNBR or a HXNBR (Hydrogenated Carboxyl Nitrile Butadiene Rubber)-PVC blend emulsion by means of the self-crosslinking capability in the absence of a vulcanizing agent by using the self-crosslinking capability of HNBR or HXNBR latex with a latex steeping method. The method comprises the following steps of: uniformly mixing HNBR or HXNBR latex with a PVC emulsion to prepare a mixed latex emulsion; and steeping, leaching and drying the mixed emulsion to obtain a glue film product. A process of the non-vulcanized glue film has the advantages of simple and practicable process, low energy consumption, capability of self-crosslinking without adding any crosslinking agent and high performance.

Owner:BEIJING UNIV OF CHEM TECH

Production line waste cleaning system for food processing

InactiveCN112460957ASpeed up evaporationPrevent recoolingDrying machines with non-progressive movementsDrying solid materialsProduction lineGear wheel

The invention discloses a production line waste cleaning system for food processing. The system comprises a drying box, the drying box is square and comprises an upper shell and a lower shell, a plurality of T-shaped supporting frames are fixedly connected to the top end of the inner wall of the upper shell, and heating pipes are arranged below the multiple supporting frames; and the multiple heating pipes are fixedly connected with the supporting frames through fixing frames, a storage plate is horizontally arranged in the lower shell, the storage plate is round and makes contact with the inner side wall of the lower shell in an abutting manner, a first motor is fixedly connected to the outer bottom face of the lower shell, and a shaft of the first motor penetrates through the lower shelland is actively connected with the lower shell. The top end of the shaft of the first motor is fixedly connected with a sliding sheet. Food waste is dried and pretreated through the heating pipes, redundant food waste is removed very well, smashing adhesion is prevented, meanwhile, a driven gear which rotates and revolves is arranged to drive a cutting blade to cut and smash the waste, and therefore the smashing quality is higher.

Owner:毛守芳

Sintering jig and manufacturing method for electronic components

The invention discloses a sintering jig and a manufacturing method for electronic components. The manufacturing method for the electronic components comprises the steps of producing blanks and producing outer electrodes on the blanks, wherein the step of producing the outer electrodes on the blanks is carried out in the sintering jig prepared from recrystallized silicon carbide, and the sintering jig is prepared through the following steps: (1) preparing a mixed material which comprises 46-63% of silicon carbide powder of 30-100mesh, 24-45% of silicon carbide powder of 1500-3000mesh, 3-10% of silicon powder of 250-500mesh, 3-8% of carbon powder of 250-500mesh and 2-4% of a binding agent; (2) processing the mixed material into a green; (3) sintering the green to obtain the sintering jig. With the adoption of the manufacturing method disclosed by the invention, the technical problem that the outer electrodes the electronic components are easy to fall off during sintering can be greatly solved, and the production yield and capacity of the electronic components can be improved.

Owner:SHENZHEN SUNLORD ELECTRONICS

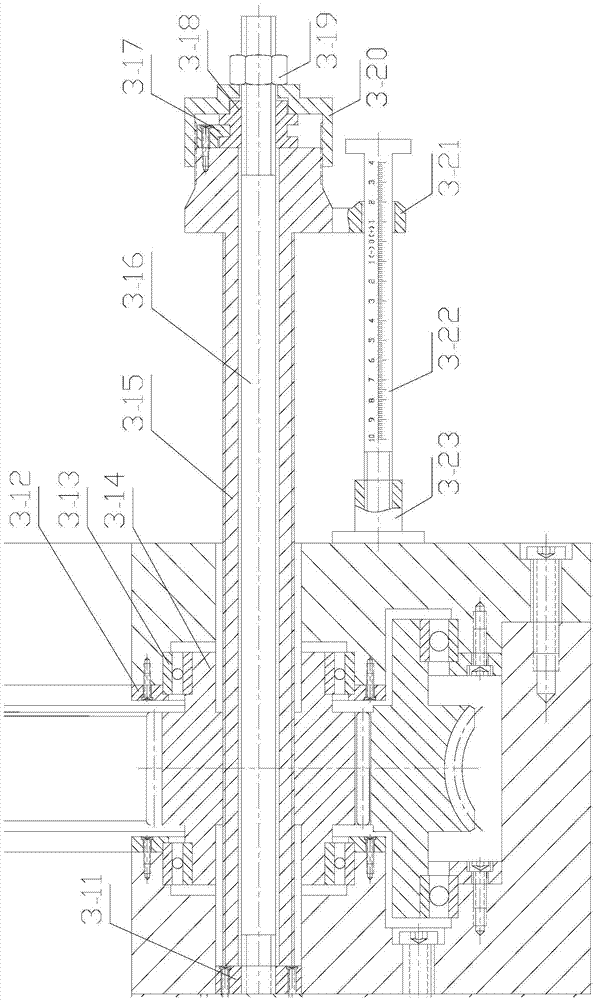

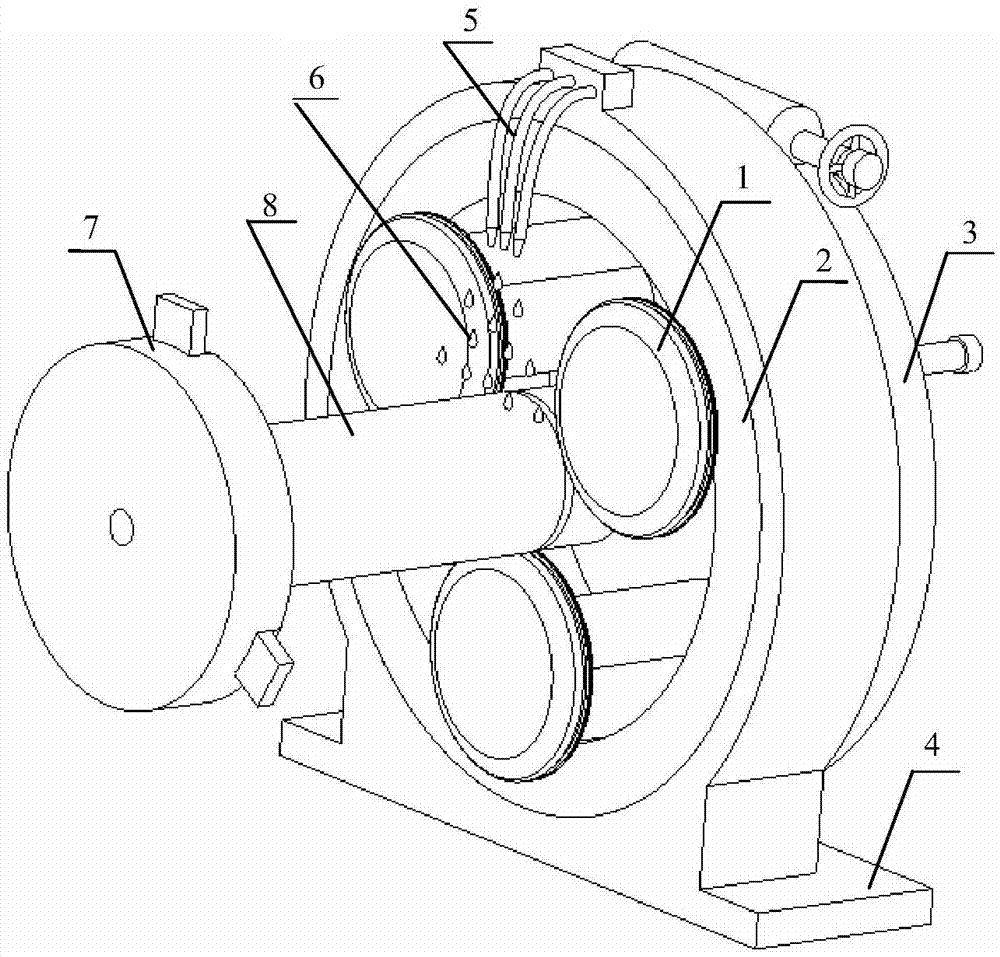

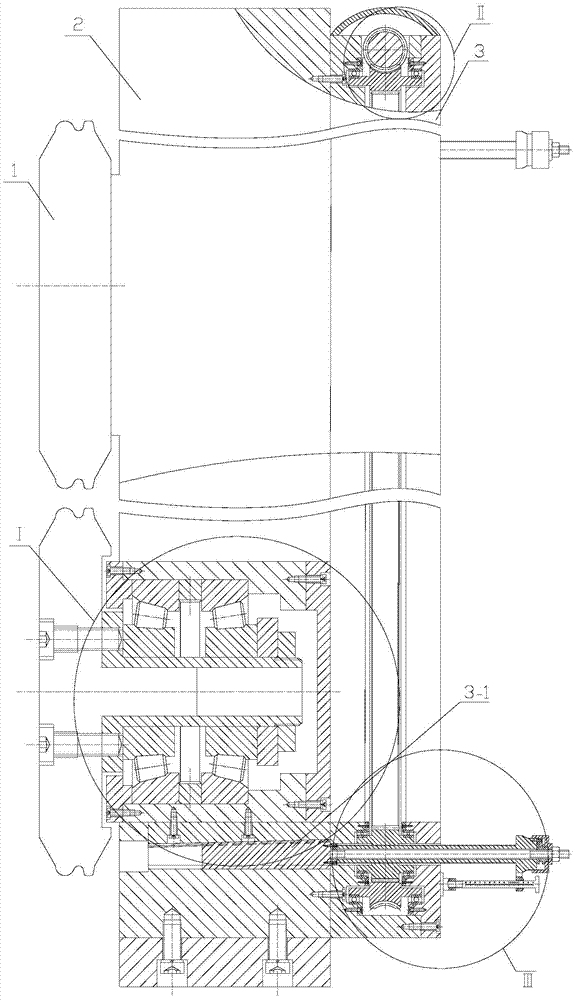

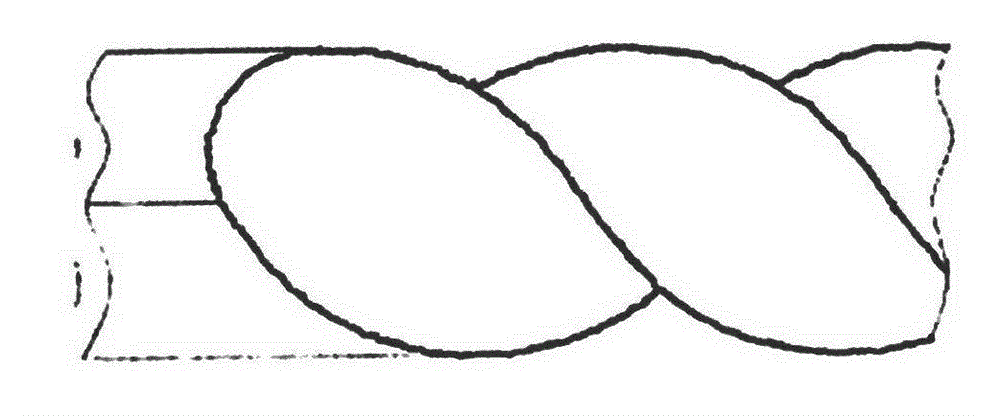

Method and device for preparing micro-nano gradient structure on surface layer of metal component

ActiveCN106929649AEfficient plastic deformationImprove production efficiencyFurnace typesHeat treatment furnacesMicro nanoMaterials preparation

The invention relates to a method and device for preparing a micro-nano gradient structure on a surface layer of a metal component and belongs to the fields of nanometer material preparation, material surface modification treatment and plastic processing. The device for preparing the micro-nano gradient structure on the surface layer of the metal component mainly comprises rollers, a roller frame, a roller advancing and retreating adjusting mechanism, a roller frame fixing and advancing mechanism and a lubricating and cooling system. The roller advancing and retreating adjusting mechanism has the functions of independent fine adjustment advancing and retreating of each roller and synchronous adjustment of advancing and retreating of the multiple rollers. By the adoption of the method and device for preparing the micro-nano gradient structure on the surface layer of the metal component, micro-nano superfine gradient structures can be achieved on the surface layers of the shaft type, the pipe type, the roller type, the spinning core model type and other types of revolution solid metal components having different diameters and large sizes, the surface quality of the processed component is high, batch production and environment-friendly production are easy to achieve, the preparation efficiency is high, and the method and device for preparing the micro-nano gradient structure on the surface layer of the metal component is beneficial for promoting industrial large-scale batch production and application of the metal material surface nanometer technology.

Owner:GRIMAT ENG INST CO LTD

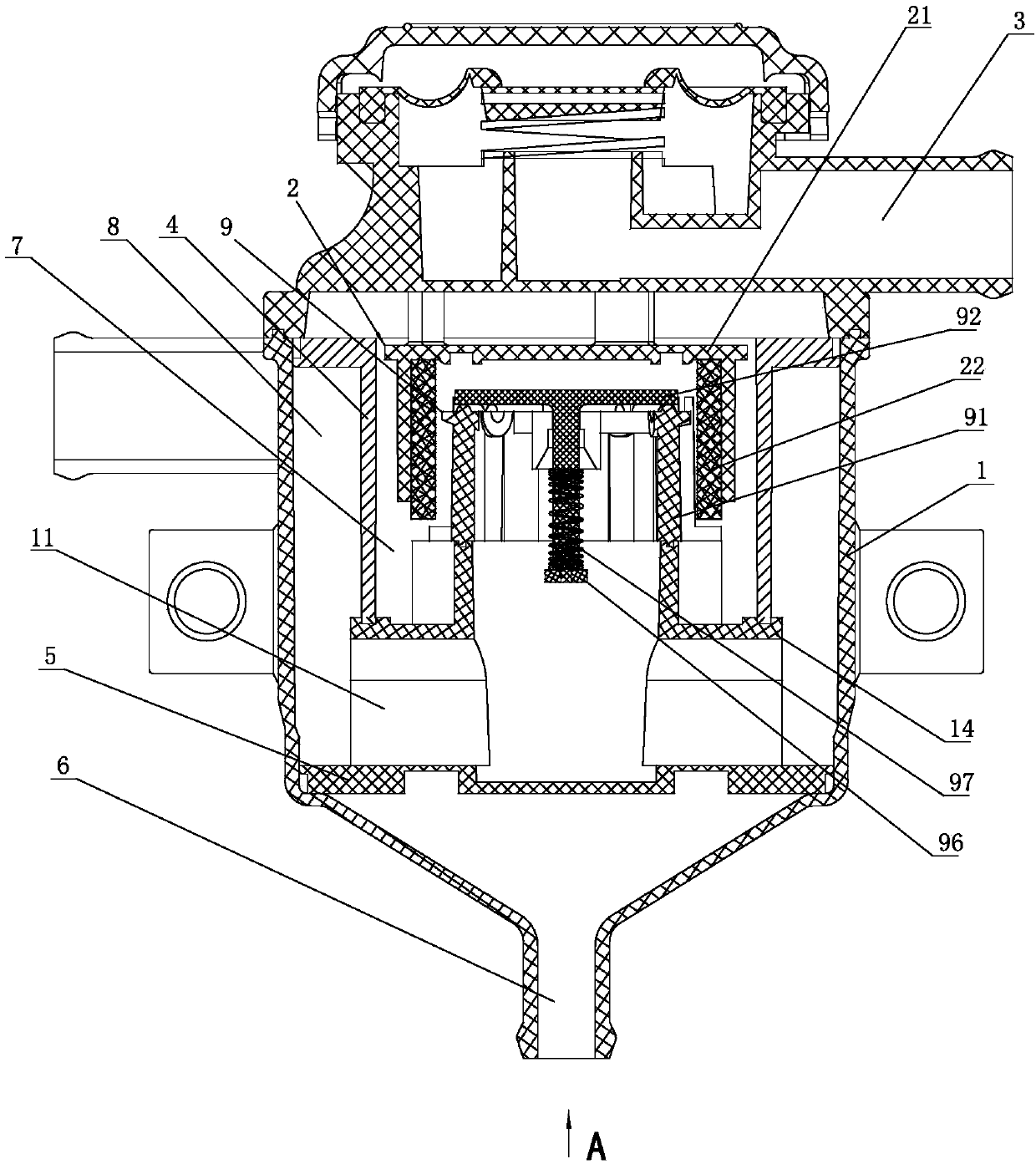

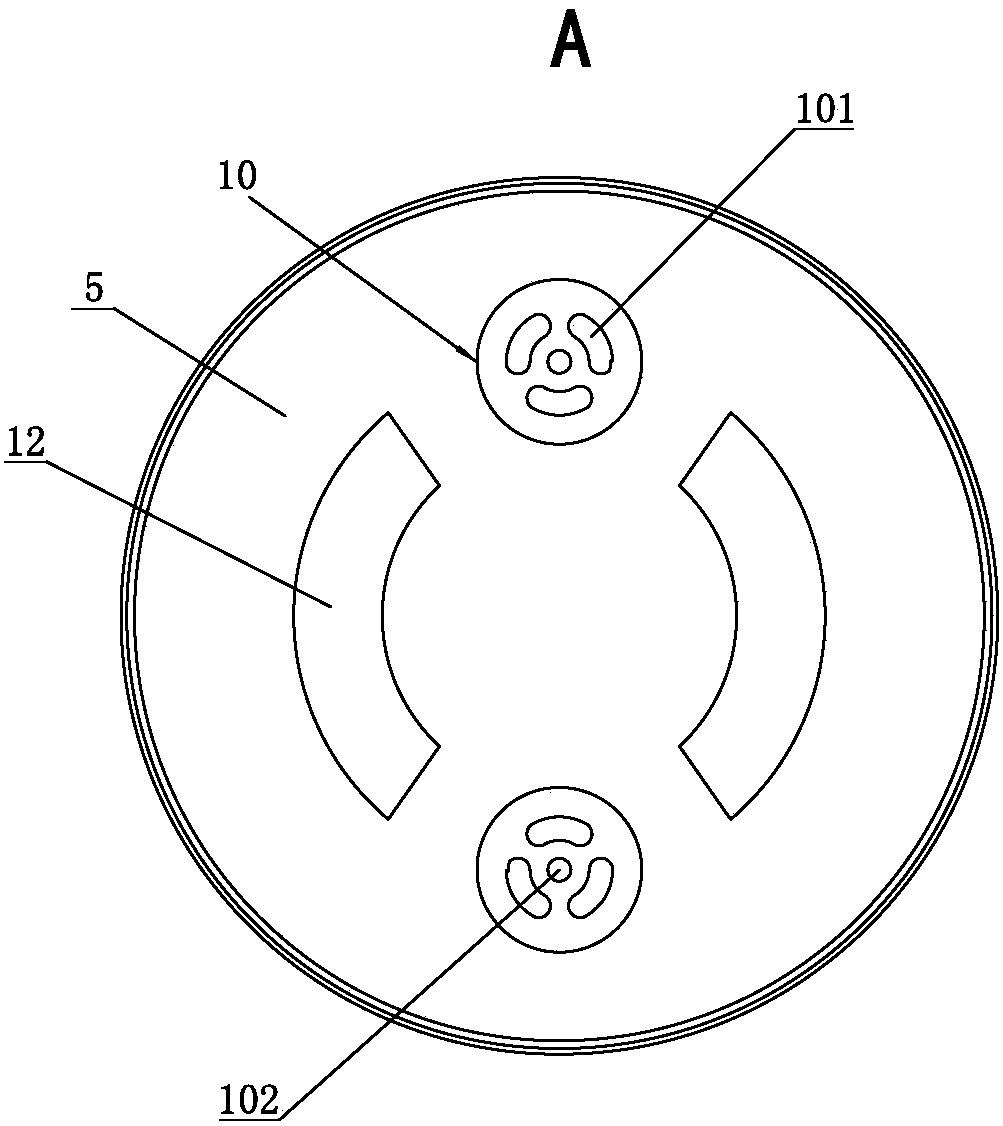

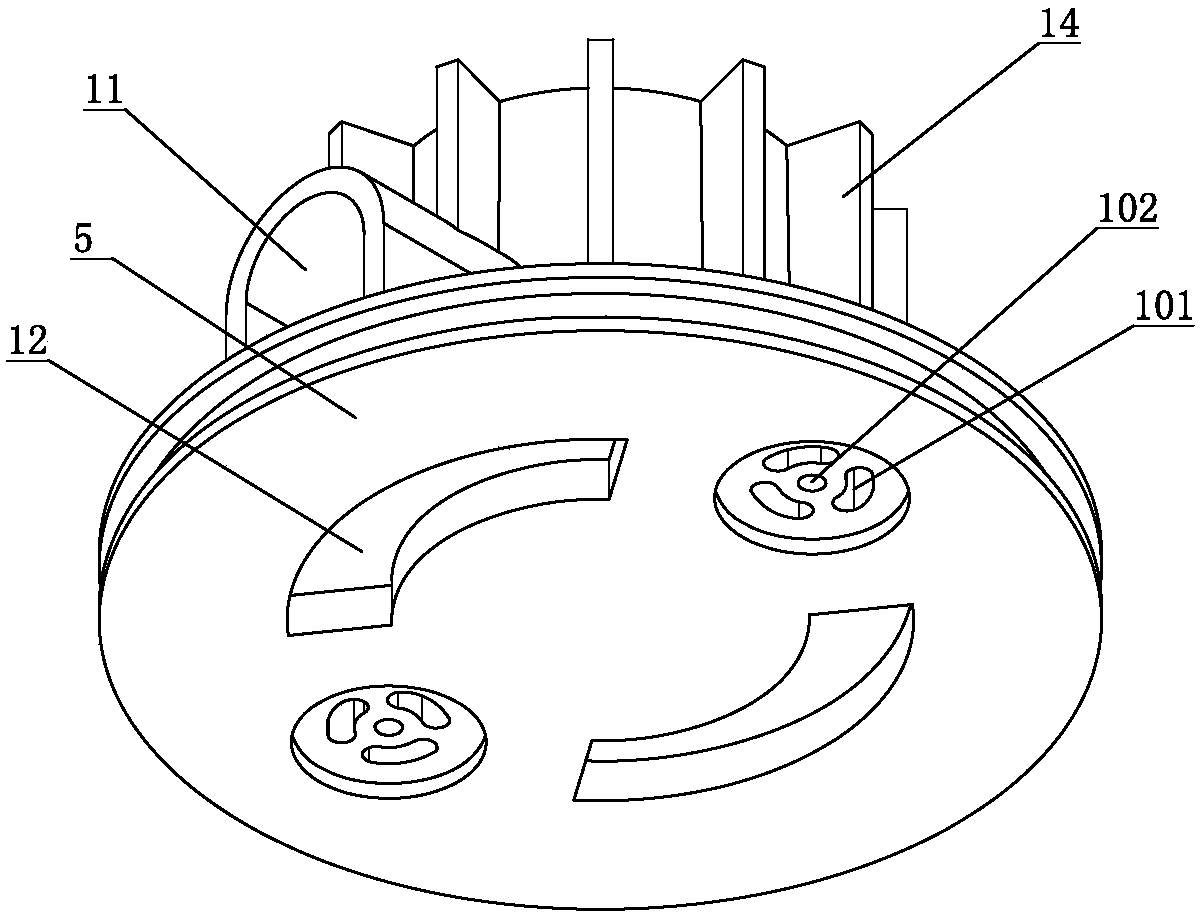

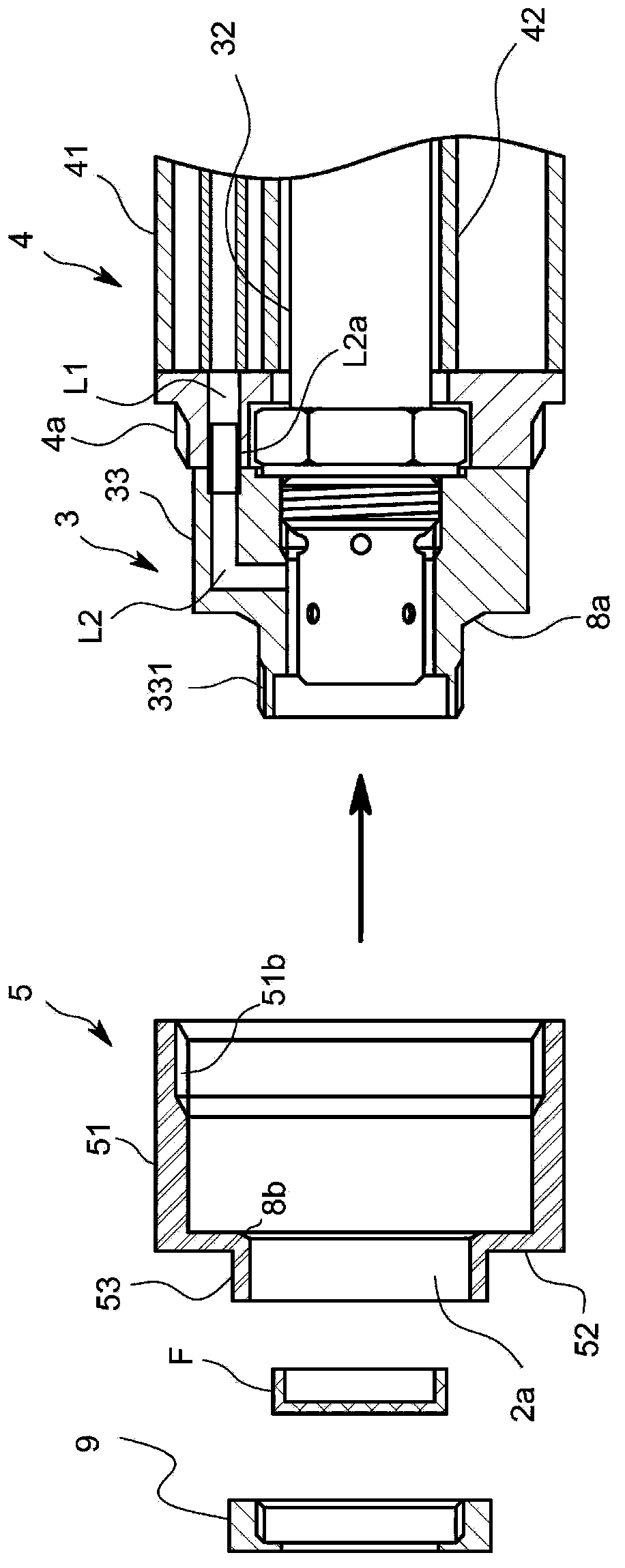

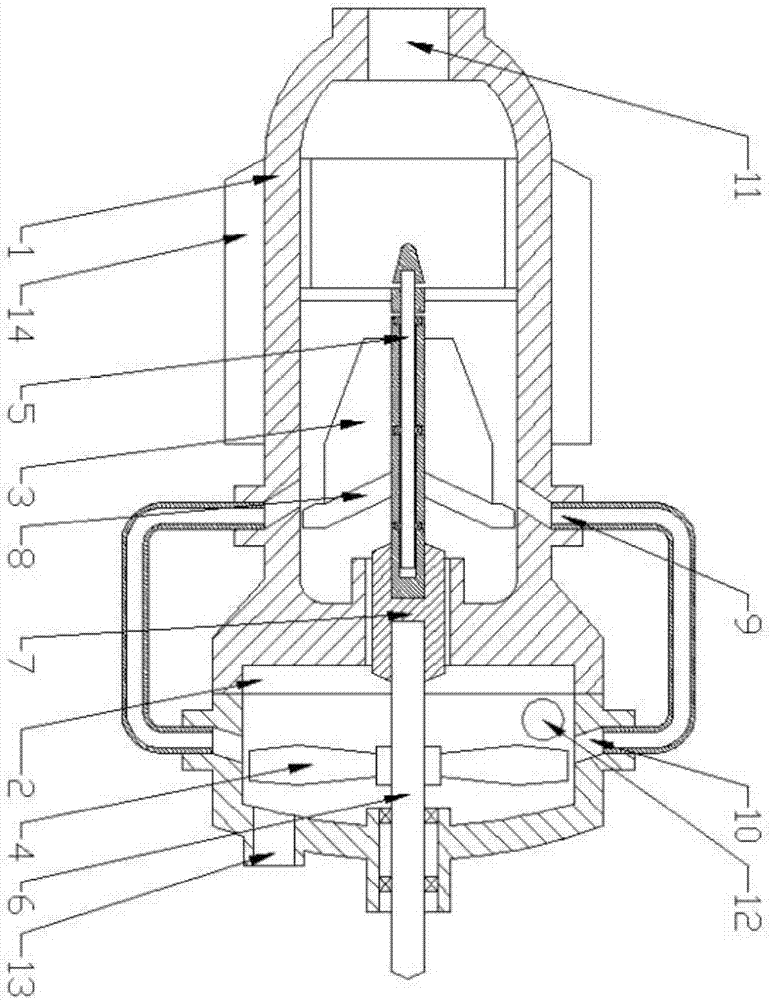

Side intake duct oil-gas separator for engine

PendingCN107816375AImprove oil and gas separation efficiencyLow retrofit costMachines/enginesCrankcase ventillationGas separationCheck valve

A side intake duct oil-gas separator for an engine comprises a shell body (1) and a filter element (2), an air outlet (3), a separation seat (4), a base (5) and an oil return port (6) are sequentiallyformed in the shell body (1) from top to bottom, the separation seat (4) separates the inner cavity of the shell body (1) into a filter cavity (7) and a spiral separation cavity (8), and the filter cavity (7) is located in the separation seat (4) to communicate with the air outlet (3). The base (5) separates the spiral separation cavity (8) from the oil return port (6), and the lower end face ofthe separation seat (4) abuts against the upper end face of the base (5). An adjusting valve (9) and at least one oil return hole (10) are formed in the base (5), the adjusting valve (9) and the filter element (2) are both located in the separation seat (4), the adjusting valve (9) is located below the filter element (2), and the upper end of the adjusting valve (9) is in the filter element (2). The oil return hole (10) is located in the projection of the separation seat (4) on the base (5), the oil return hole (10) communicates with the filter cavity (7) and the oil return port (6), and a single-way valve is arranged in the oil return hole (10). An air inlet channel (11) for enabling the filter cavity (7) to communicate with the spiral separation cavity (8) is formed in the upper end of the base (5). Compared with the prior art, the side intake duct oil-gas separator has the characteristics of being low in improvement cost, not liable to blow back, high in oil and gas separation efficiency and good in using stability.

Owner:宁海县雄达模塑有限公司

Preparation method of trimetazidine hydrochloride slow release microcapsules

InactiveCN105769815ASimple preparation stepsLong-lasting effectOrganic active ingredientsSenses disorderPolyglutamic acidSolubility

The invention discloses a preparation method of trimetazidine hydrochloride slow release microcapsules, and belongs to the technical field of medicine preparation. The preparation method comprises the following steps: mixing chitosan, starches and sodium carbonate to obtain a mixture, mixing the mixture with isoamylase, adjusting the pH with an acidic solution, filtering to obtain filtrates, squeezing the filtrates, smashing and screening the filtrates, mixing the filtrates with polyglutamic acid and distilled water to obtain a mixed solution, mixing the mixed solution with dietary fibers and sodium alga acid, discharging a material which is a wall material solution, mixing the wall material solution with a mixed solution prepared from trimetazidine hydrochloride and a mannitol solution, spraying a calcium chloride solution, and stewing, drying, washing and freeze-drying products to obtain the trimetazidine hydrochloride slow release microcapsules. The preparation method has the benefits that the preparation steps are simple, and the solutions difficultly get sticky in the preparation process; the solubility of the obtained product in water is reduced by 23.3 percent or above; after being used, the trimetazidine hydrochloride slow release microcapsules can last for a long time, the administration frequency is reduced by 15 to 20 percent, and the biological utilization rate is increased by 20 to 30 percent.

Owner:袁春华

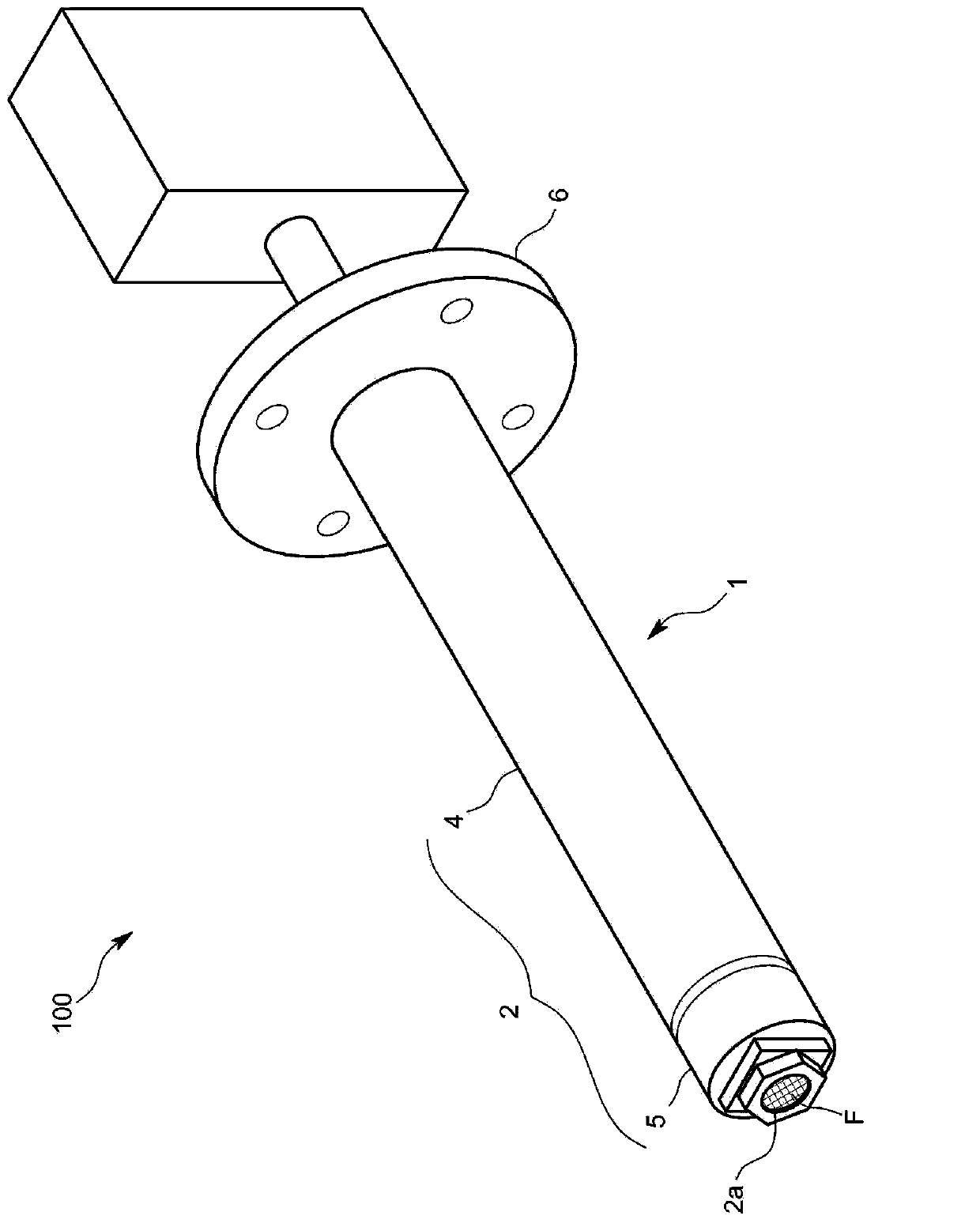

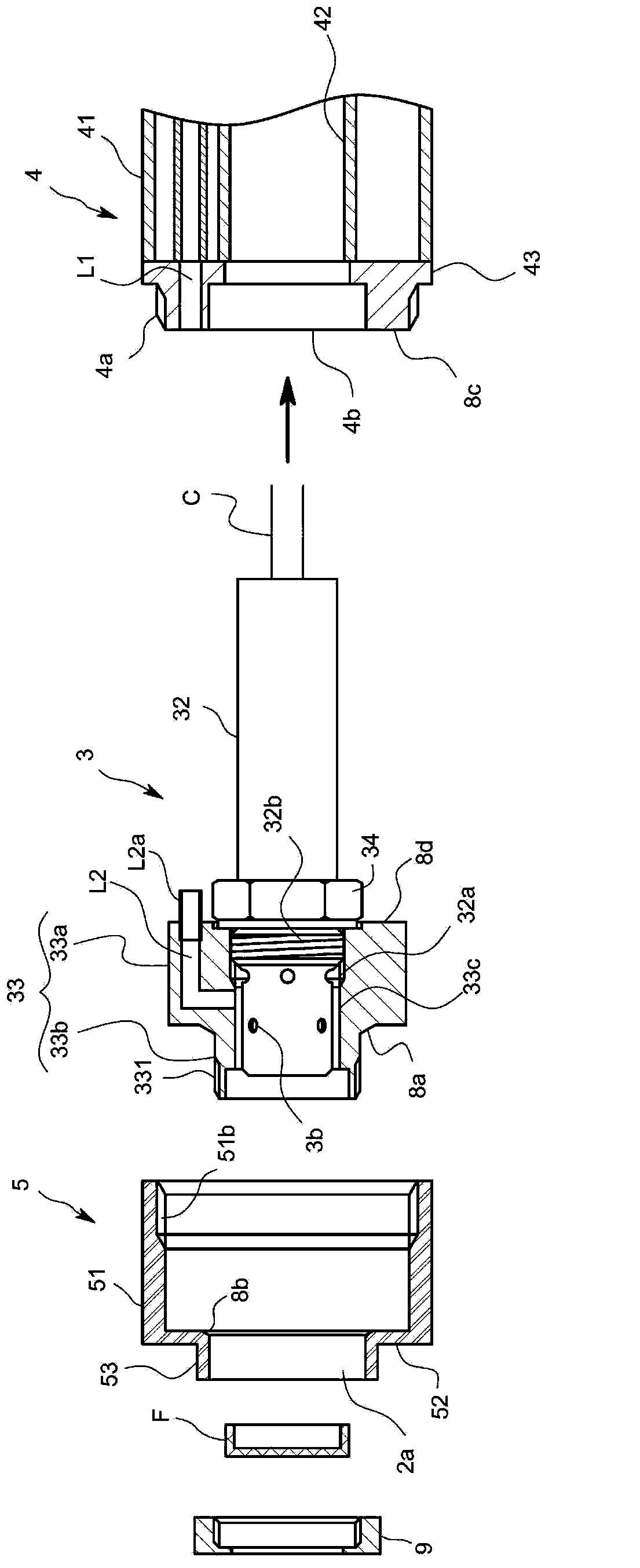

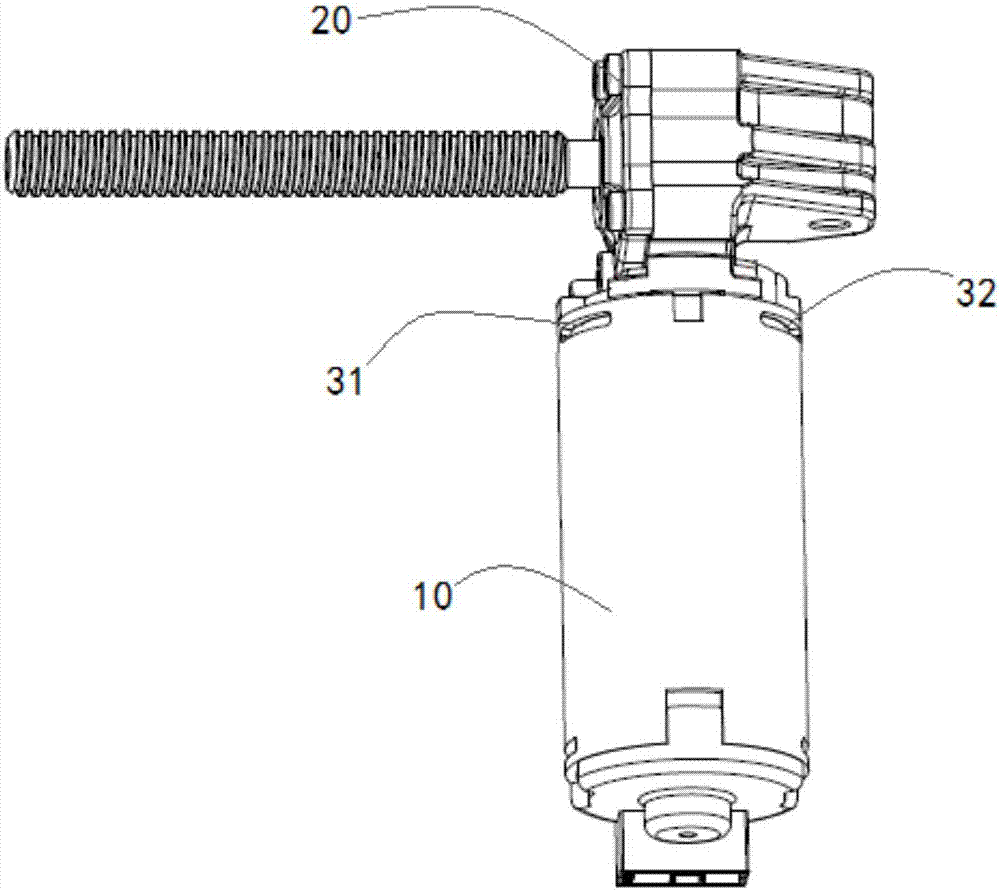

Exhaust gas analyzer and probe unit

InactiveCN103376306AAvoid hidden dangersImprove insulation performanceSamplingEngine testingProcess engineeringExhaust gas

The invention provides an exhaust gas analyzer which can ensure satisfactory operation when a gas sensor is replaced during the first-stage assembling, the assembling and the maintenance and a probe unit. The exhaust gas analyzer includes a gas sensor for detecting the specified content in waste gas and a sleeve. The sleeve is provided with a main body for inserting the gas sensor inside an inserting hole and a cap component threadedly connected with the main body and being configured to covering the insert hole. Meanwhile, the gas sensor is clamped by the cap component and the main body to be fixed in the sleeve by means of threadedly connecting the cap component to the main body.

Owner:HORIBA LTD

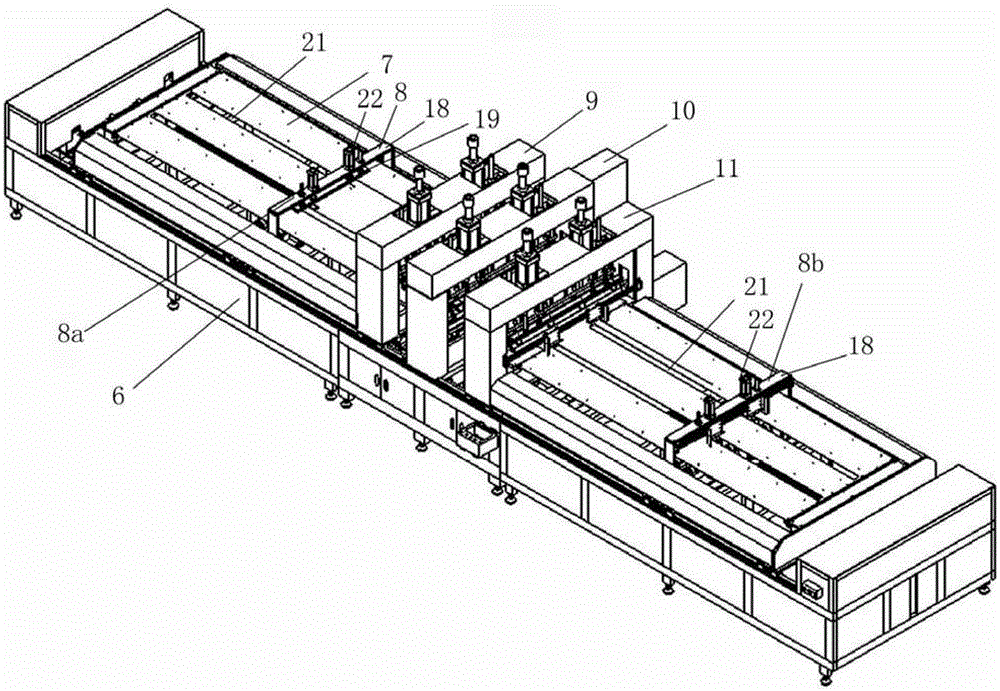

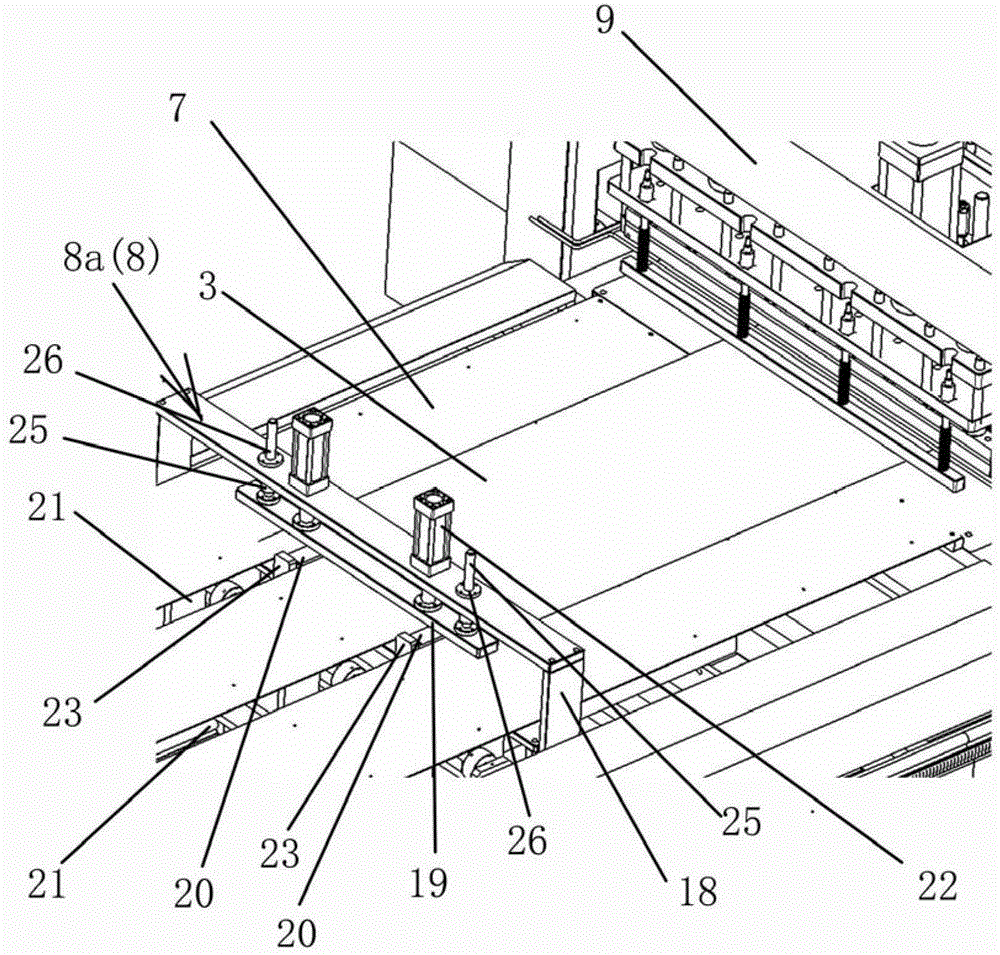

Headpiece of creasing press for brattice of brattice case

ActiveCN103203861ANot prone to stickingGood crease qualityEngineeringElectrical and Electronics engineering

The invention discloses a headpiece of a creasing press for a brattice of a brattice case. The headpiece is characterized by comprising a frame body and a heating device and a push type broach device which are arranged on the frame body, wherein the heating device and the push type broach device are sequentially arranged on the frame body in the feed-in direction of a to-be-machined brattice plate on a working table of a creasing press, the position of the heating device is used as a heating station, and the position of the push type broach device is used as a mould pressing station; the heating device comprises a heating body arranged towards the working table of the creasing press from top to bottom, and the heating body is of a long strip shape along the width direction of the working table; the push type broach device comprises a hydraulic cylinder and a push type broach die; and the push type broach die is arranged towards the to-be-machined brattice plate on the working table of the creasing press from top to bottom, the push type broach die is of a long strip shape in the width direction of the working table of the creasing press, and the hydraulic cylinder drives the push type broach die to act. The headpiece is developed according to the characteristic of a thick plastic hollow plate of the brattice of the brattice case, two steps, i.e. sequential heating and indentation pressing are performed, sticking is unlikely to occur, and a prepared indentation has good quality.

Owner:SUZHOU LIANGCAI LOGISTICS TECH

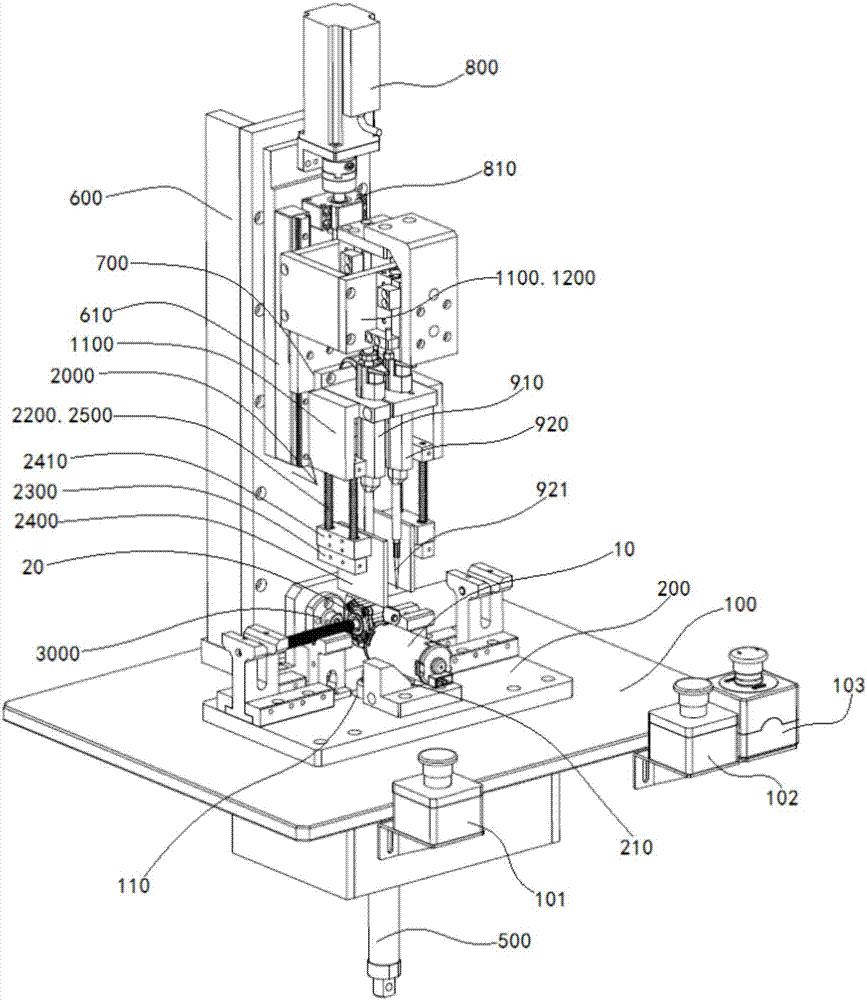

Glue dispending machine

ActiveCN107413586ANot prone to stickingEasy to operateLiquid surface applicatorsCoatingsMechanical engineeringEngineering

The invention discloses a glue dispensing machine. The glue dispensing machine comprises a working platform, a positioning base, a mounting vertical column, a glue dispensing mounting sliding seat, a glue dispensing servo motor, liquid moving devices, a glue absorbing air cylinder, a glue discharging air cylinder and a PLC, wherein the positioning base is arranged on a working platform; the mounting vertical column is vertically arranged on the working platform and positioned on one side of the positioning base; the glue dispensing mounting sliding seat is installed on a sliding rail of the vertical column in a sliding configuration mode and positioned above the positioning base; the glue dispensing servo motor is mounted on a mounting vertical column and is connected with the glue dispensing mounting sliding seat trough a transmission mechanism; the liquid moving devices are horizontally mounted on the glue dispensing mounting sliding seat at intervals; the glue absorbing air cylinder is installed in the glue dispensing mounting sliding seat; the glue discharging air cylinder is installed in the glue dispensing mounting sliding seat; and the PLC is connected with the glue dispensing servo motor, the glue absorbing air cylinder and the glue discharging air cylinder. According to the glue dispensing machine, the liquid moving devices are adopted for glue dispensing, glue bonding phenomenon is not easy to occur in the liquid moving devices, just a glue dispensing needle is replaced if bonding is appeared in the glue dispensing needle, operation is simple and convenient.

Owner:上海胜华波汽车电器有限公司

Technology for removing defects of connection thread of petroleum drilling tool

The name of the invention is a technology for removing defects of a connection thread of a petroleum drilling tool, and the invention relates to the field of drilling tool processing of the petroleum industry. A thread part is scanned by a laser after a lathe machines a thread; the defects of the thread part after being machined are fused and the surface of the thread is subjected to phase-change hardening, and a thread work surface is grinded by a thread grinding head, so as to improve the smoothness of the thread surface and ensure the hardness of a hardened layer.

Owner:陈伟琛

Petroleum mixing and conveying pump

InactiveCN106968960AReduce flow viscosityHigh speed driveSpecific fluid pumpsPump componentsImpellerEngineering

The invention relates to a petroleum mixing and conveying pump. The pump casing body is divided into an inflow cavity and a driving cavity; the constricted end of the inflow cavity is provided with a feeding port; A pressure impeller with a conical table structure is rotatably connected to the tail, and the pressure impeller includes a support block. A number of driving blades coplanar with the axis of the support block are arranged in an array on the support block. A plurality of discharge nozzles are arranged in an annular array on the inner wall of the inflow cavity corresponding to the distribution plate. A centrifugal impeller is rotatably connected in the driving cavity. The centrifugal impeller includes a rotating block. The annular array is provided with a number of centrifugal blades on the rotating block. The centrifugal impeller The support block and the rotating block of the pressure impeller are coaxially rotated and fixed, and a number of inflow nozzles are arranged in an annular array on the inner wall of the driving cavity. The inner wall is provided with a liquid inlet, and a liquid discharge port is provided at the end of the axis of the drive cavity.

Owner:YANCHENG JINRUI PETROLEUM MACHINERY CO LTD

Novel creasing machine nose of boarding of boarding box

The invention provides a novel creasing machine nose of a boarding of a boarding box. The novel creasing machine nose is characterized by comprising a frame body and a crease line machining device which is arranged on a working tabletop of a creasing machine from top to bottom, wherein the crease line machining device comprises a hydraulic cylinder and a rotary shaft type machining head connected with an acting end of the hydraulic cylinder; the rotary shaft type machining head comprises a rotary shaft, a heating device, a pressing cutter mould and a rotary driving device; the rotary shaft is arranged along the width direction of the working tabletop of the creasing machine, and the rotary shaft is rotatably connected with the acting end of the hydraulic cylinder; a heating body and the pressing cutter mould are arranged on the periphery of the rotary shaft; and the rotary driving device acts on the rotary shaft to drive the rotary shaft to rotate, so that the heating body and the pressing cutter mould on the rotary shaft are alternatively rotated to the position which aligns to the working tabletop of the creasing machine. According to the novel creasing machine nose of the boarding of the boarding box, aiming at the development property of a thick plastic hollow plate of the boarding of the boarding box, a heating step is firstly carried out and a step of pressing a crease line is carried out, and the operation is realized by two steps, so that materials are not easily stuck and the quality of the manufactured crease line is good.

Owner:苏州中集良才科技有限公司

Preparation process of compound honeysuckle film-coated tablet

InactiveCN111956696AMoisture-proofWith darkDigestive systemPharmaceutical non-active ingredientsPolyvinyl alcoholPolyethylene glycol

The invention discloses a preparation process of a compound honeysuckle film-coated tablet. The method comprises the following steps: heating and extracting honeysuckle, and collecting honeysuckle filtrate, adding forsythia suspensa and scutellaria baicalensis into an extraction tank, adding water, decocting, filtering, combining filtrates, and mixing with the honeysuckle filtrate, concentrating to obtain an extract, and drying to obtain dry paste powder, adding starch, soybean gum, konjac glucomannan and phlorizin into the dry extract powder, uniformly mixing, uniformly mixing with magnesiumstearate, and tabletting to obtain the compound lonicerae flos tablets. Adding sodium carboxymethyl cellulose, polyethylene glycol, polyvinyl alcohol, beta-cyclodextrin, a plasticizer and a coloring agent into a high-speed dispersion machine to prepare a coating solution, and placing the plain tablets and the coating solution in a coating machine for spraying and coating, and drying to obtain thecompound honeysuckle film coated tablets. The compound honeysuckle flower film-coated tablet prepared by the invention has the advantages of moisture resistance, light shielding, taste masking, low water absorption and the like, is not easy to generate cracks, spots and mildew spots, improves the stability of the medicine, and prolongs the storage period, the processing fluidity is good and the production efficiency is improved.

Owner:右江民族医学院

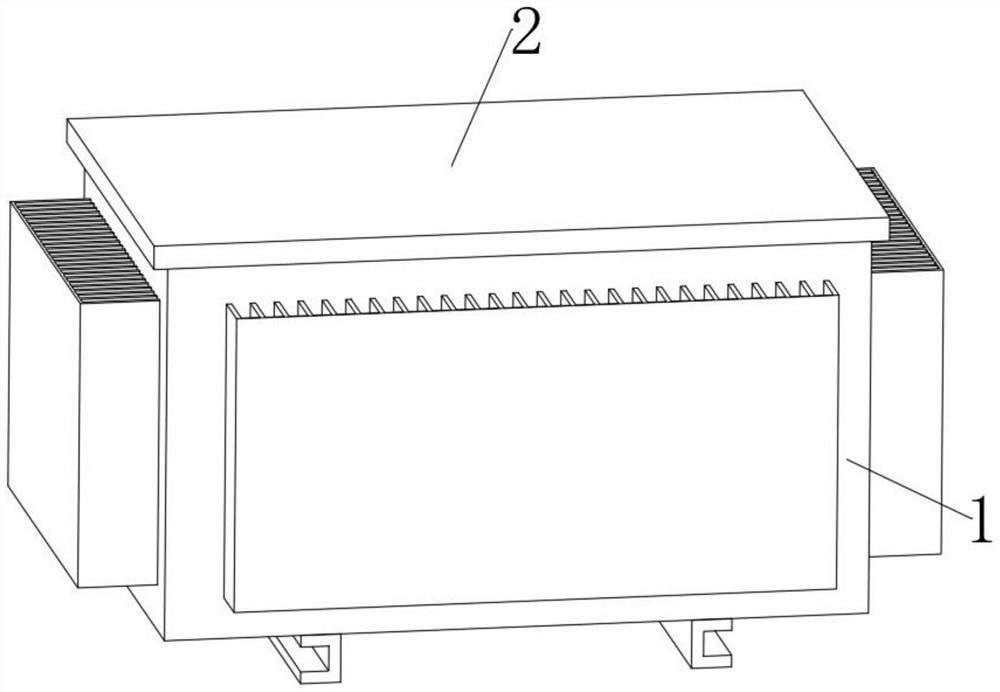

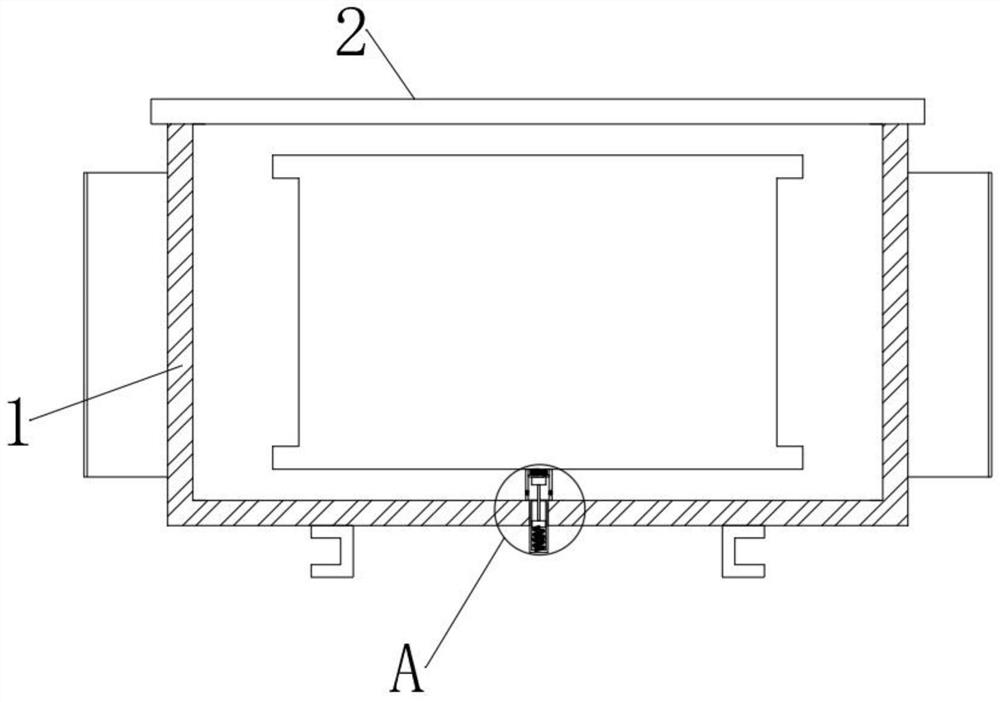

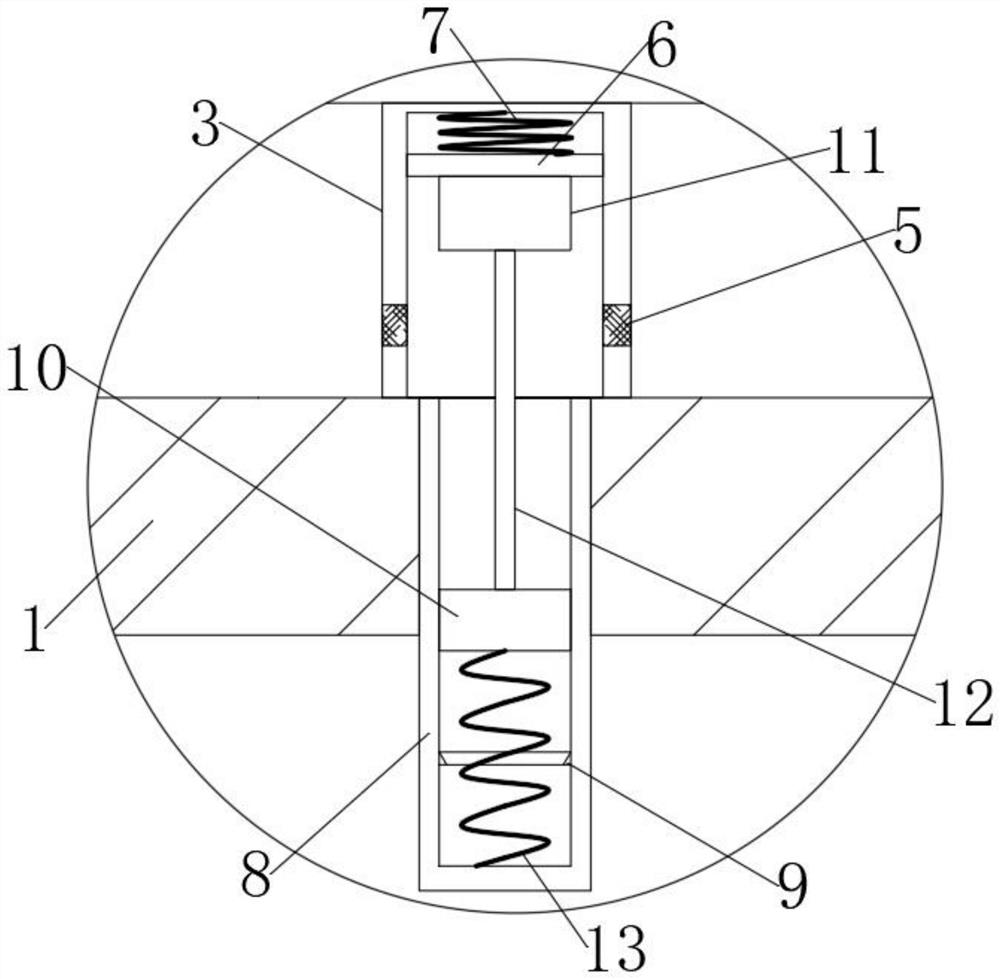

Oil-immersed transformer with sealing oil leakage prevention function

InactiveCN113077967ANot easy to cause leakageNot easy to cause secondary pollutionTransformers/inductances coolingTransformers/inductances casingsOil canThermodynamics

The invention discloses an oil-immersed transformer with a sealing oil leakage prevention function, and belongs to the field of oil-immersed transformers. In the scheme, an oil outlet hole formed in the lower end of a transformer main body provides an oil leakage position for the whole transformer main body; before a sealing piece of a transformer body cannot complete sealing work, cooling oil can flow into a spiral pipe from an oil outlet hole in advance under the action of oil pressure, along with the increase of the mass of the cooling oil, a bearing piston downwards presses the position of a check ring, an alarm is given through a pressure-sensitive sensor installed in the check ring, technicians are reminded to maintain and repair in time, oil seepage points of the oil-immersed transformer which is installed and sealed improperly can be controlled, overflowing cooling oil is not prone to adhering to the surface of the oil-immersed transformer, normal heat dissipation of the oil-immersed transformer is not prone to being affected, fire accidents are not prone to being induced, and excessive influence on the surrounding environment of the oil-immersed transformer is not easily caused.

Owner:NANTONG HAIWANG ELECTRIC

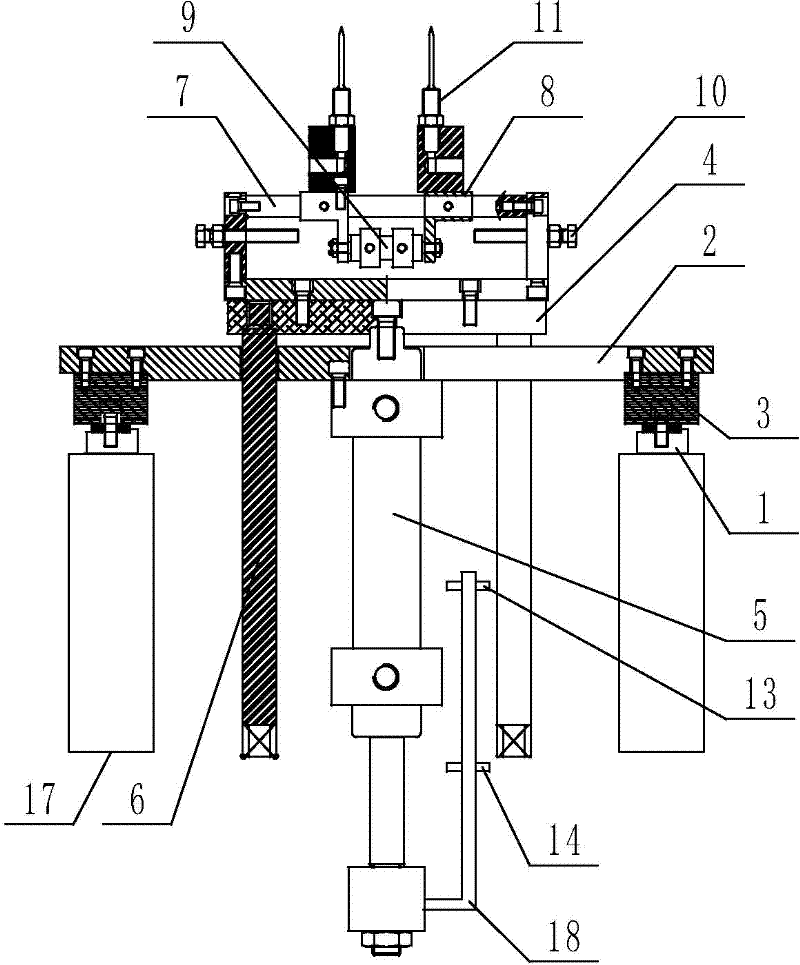

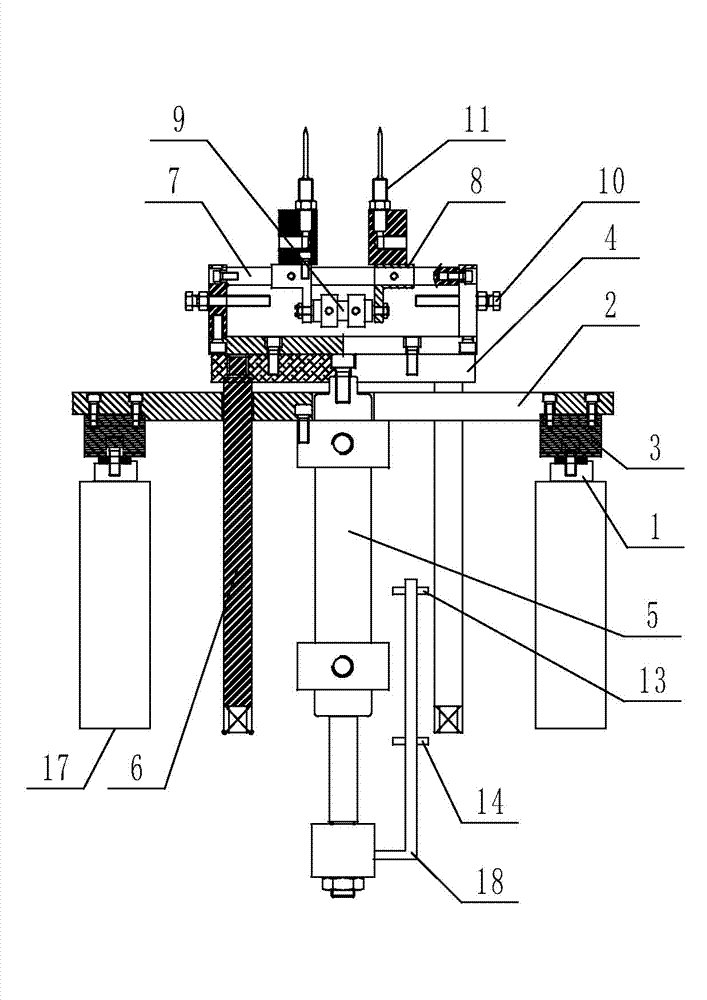

Lower blowing device in respiration hood production line

The invention relates to a lower blowing device in a respiration hood production line. The lower blowing device comprises two guide rails arranged on an opening and closing mold bracket and a front and back moving plate; slide blocks are arranged at the lower parts of two ends of the front and back moving plate; the slide blocks are connected with the guide rails; return springs are arranged on the guide rails positioned at two sides of the slide blocks; an up and down moving plate is arranged above the front and back moving plate; an up and down cylinder is vertically arranged in the front and back moving plate; the cylinder body of the up and down cylinder is connected with the front and back moving plate; a telescopic rod of the up and down cylinder is connected with the up and down moving plate; two supporting guide rods are transversely arranged in the up and down moving plate; two supporting slide blocks are arranged on the supporting guide rods; a double-output shaft cylinder is arranged between the two supporting slide blocks; two telescopic rods of the double-output shaft cylinder are connected with the two supporting slide blocks respectively; and blowing pins are arranged above the two supporting slide blocks respectively. The lower blowing device is suitable for the respiration hood production line, is arranged below a die, can improve the work efficiency, and can prevent a blank positioned in the die from being stuck.

Owner:张家港市同创机械有限公司

Non-vulcanized glue film of hydrogenated butyronitrile-polyvinyl chloride blended emulsion and preparation and application thereof

The invention discloses a non-vulcanized glue film of a hydrogenated butyronitrile-polyvinyl chloride blended emulsion and a preparation method and an application thereof, which belong to a chemical product and a preparation method thereof. The method is characterized in that: a non-vulcanized self-crosslinking HNBR (Hydrogenated Nitrile Butadiene Rubber) / PVC (Polyvinyl Chloride) latex film is prepared from HNBR or a HXNBR (Hydrogenated Carboxyl Nitrile Butadiene Rubber)-PVC blend emulsion by means of the self-crosslinking capability in the absence of a vulcanizing agent by using the self-crosslinking capability of HNBR or HXNBR latex with a latex steeping method. The method comprises the following steps of: uniformly mixing HNBR or HXNBR latex with a PVC emulsion to prepare a mixed latex emulsion; and steeping, leaching and drying the mixed emulsion to obtain a glue film product. A process of the non-vulcanized glue film has the advantages of simple and practicable process, low energy consumption, capability of self-crosslinking without adding any crosslinking agent and high performance.

Owner:BEIJING UNIV OF CHEM TECH

Hoarding box hoarding crease machine head

The invention discloses a headpiece of a creasing press for a brattice of a brattice case. The headpiece is characterized by comprising a frame body and a heating device and a push type broach device which are arranged on the frame body, wherein the heating device and the push type broach device are sequentially arranged on the frame body in the feed-in direction of a to-be-machined brattice plate on a working table of a creasing press, the position of the heating device is used as a heating station, and the position of the push type broach device is used as a mould pressing station; the heating device comprises a heating body arranged towards the working table of the creasing press from top to bottom, and the heating body is of a long strip shape along the width direction of the working table; the push type broach device comprises a hydraulic cylinder and a push type broach die; and the push type broach die is arranged towards the to-be-machined brattice plate on the working table of the creasing press from top to bottom, the push type broach die is of a long strip shape in the width direction of the working table of the creasing press, and the hydraulic cylinder drives the push type broach die to act. The headpiece is developed according to the characteristic of a thick plastic hollow plate of the brattice of the brattice case, two steps, i.e. sequential heating and indentation pressing are performed, sticking is unlikely to occur, and a prepared indentation has good quality.

Owner:苏州中集良才科技有限公司

Novel creasing machine nose of boarding of boarding box

The invention provides a novel creasing machine nose of a boarding of a boarding box. The novel creasing machine nose is characterized by comprising a frame body and a crease line machining device which is arranged on a working tabletop of a creasing machine from top to bottom, wherein the crease line machining device comprises a hydraulic cylinder and a rotary shaft type machining head connected with an acting end of the hydraulic cylinder; the rotary shaft type machining head comprises a rotary shaft, a heating device, a pressing cutter mould and a rotary driving device; the rotary shaft is arranged along the width direction of the working tabletop of the creasing machine, and the rotary shaft is rotatably connected with the acting end of the hydraulic cylinder; a heating body and the pressing cutter mould are arranged on the periphery of the rotary shaft; and the rotary driving device acts on the rotary shaft to drive the rotary shaft to rotate, so that the heating body and the pressing cutter mould on the rotary shaft are alternatively rotated to the position which aligns to the working tabletop of the creasing machine. According to the novel creasing machine nose of the boarding of the boarding box, aiming at the development property of a thick plastic hollow plate of the boarding of the boarding box, a heating step is firstly carried out and a step of pressing a crease line is carried out, and the operation is realized by two steps, so that materials are not easily stuck and the quality of the manufactured crease line is good.

Owner:SUZHOU LIANGCAI LOGISTICS TECH

Machining method for highlight chamfering of mobile phone window organic glass panel

ActiveCN107234493AImprove surface roughnessEasy to operateEdge grinding machinesAbrasion apparatusSurface roughnessSingle crystal

The invention relates to a machining method for highlight chamfering of a mobile phone window organic glass panel, and belongs to the technical field of glass chamfering machining. To solve the existing problem that polishing is needed after chamfering, the machining method for highlight chamfering of the mobile phone window organic glass panel is provided. The method comprises the steps that a plurality of single pieces of organic glass are laminated to form rectangular blocky glass, and the rectangular blocky glass is fixed; a tool with a monocrystal diamond blade in a CNC machining machine tool is used for conducting chamfering cutting on the rectangular blocky glass, the monocrystal diamond blade is formed by machining monocrystal diamond raw materials with the grain size smaller than or equal to 4 mm, and after cutting, each single piece of organic glass has a corresponding chamfer, and the mobile phone window organic glass panel obtained after machining and chamfering is obtained. According to the machining method, polishing does not need to be conducted after chamfering, operation procedures are simplified, the formed chamfers have the effects of highlight and a good bright border effect, and good surface roughness and glossiness effects are achieved.

Owner:江门市威瑞电子科技有限公司

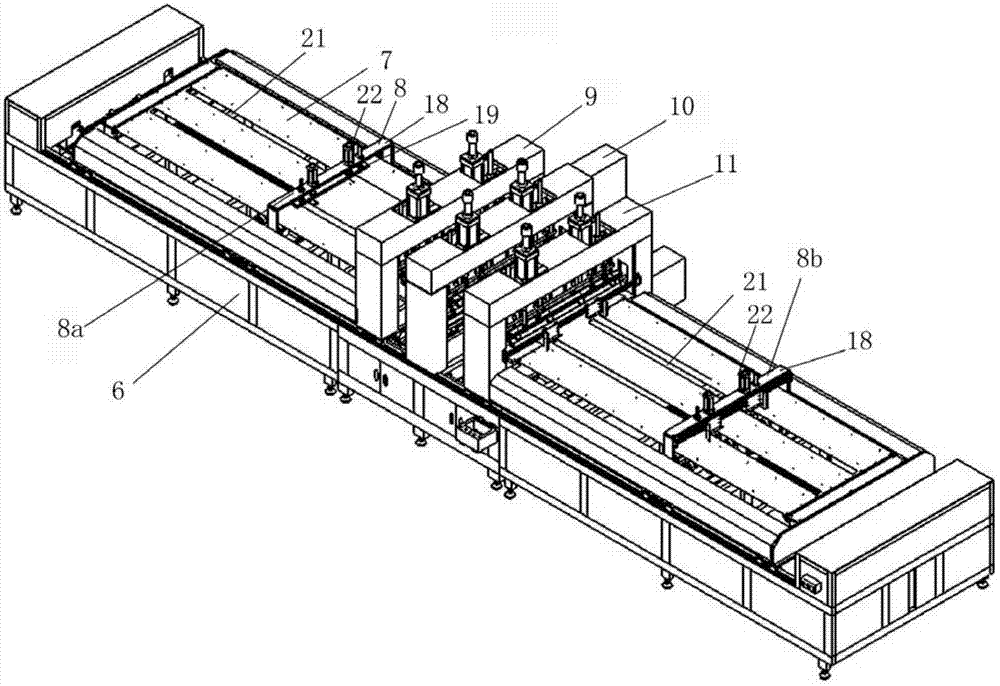

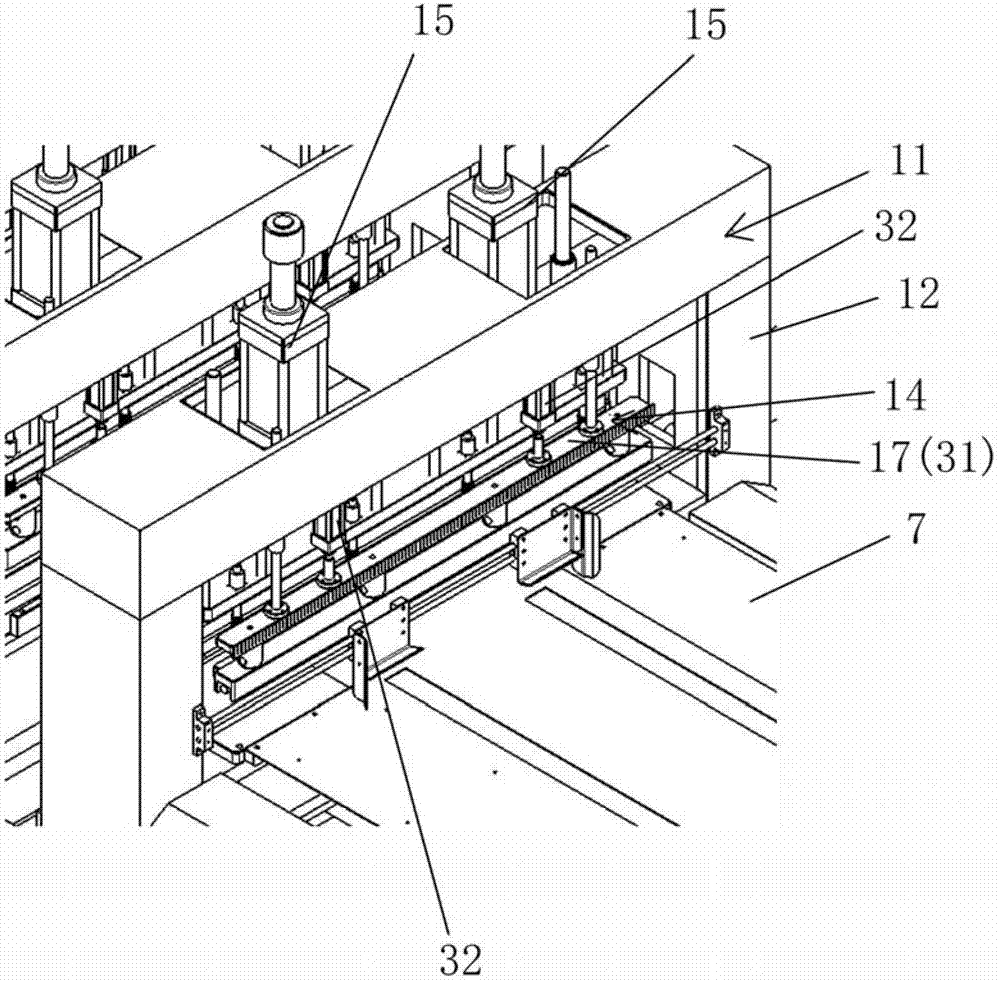

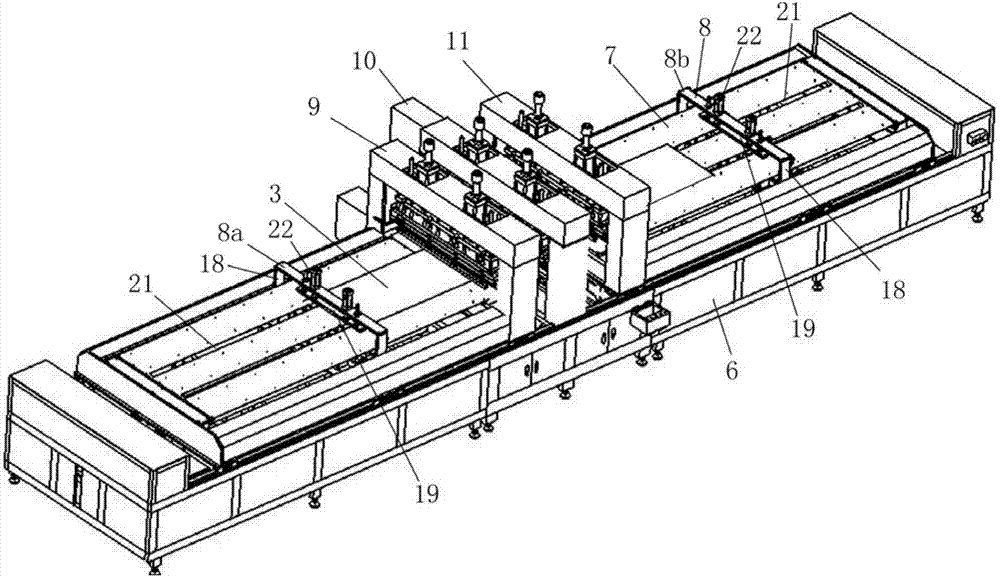

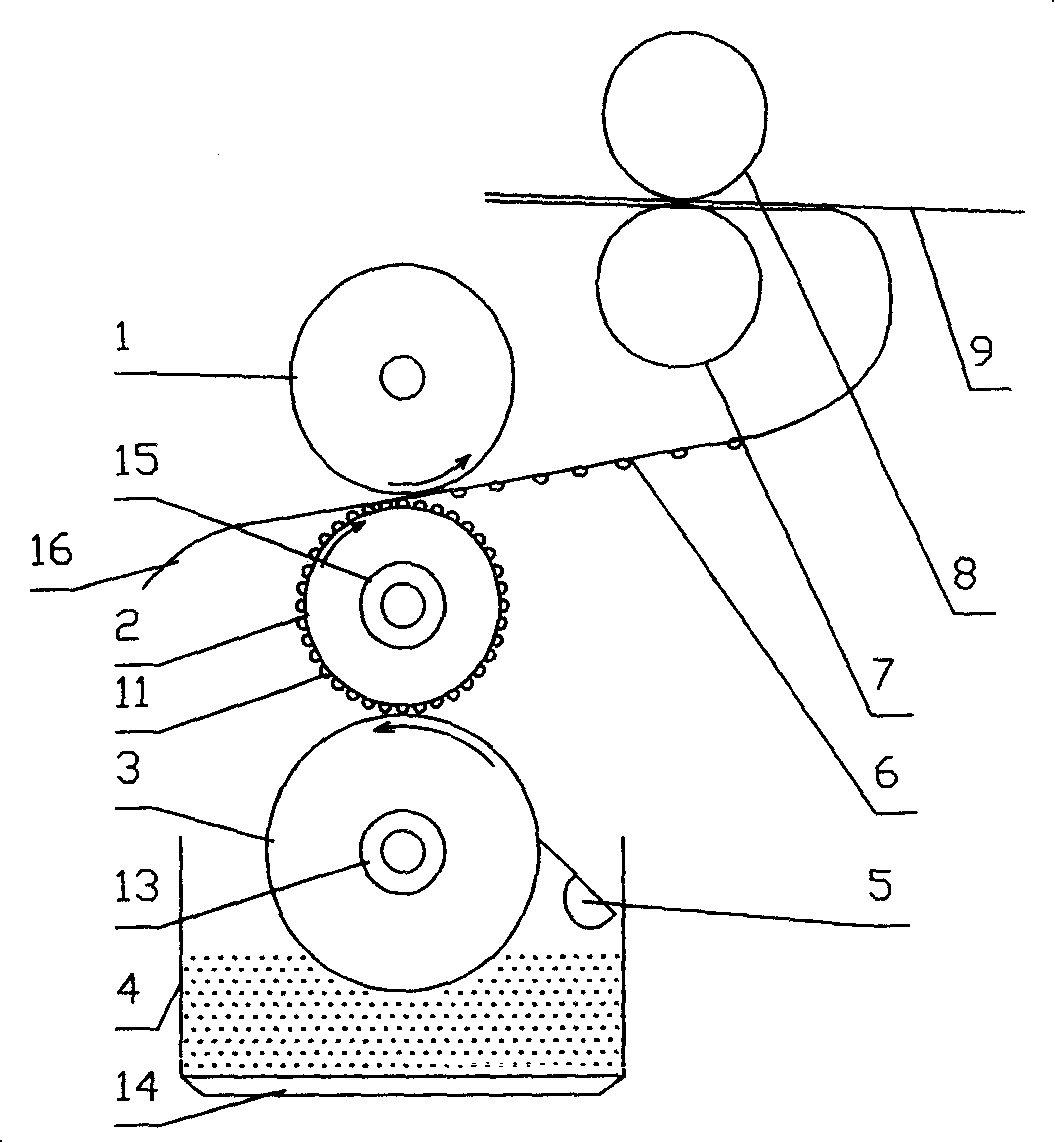

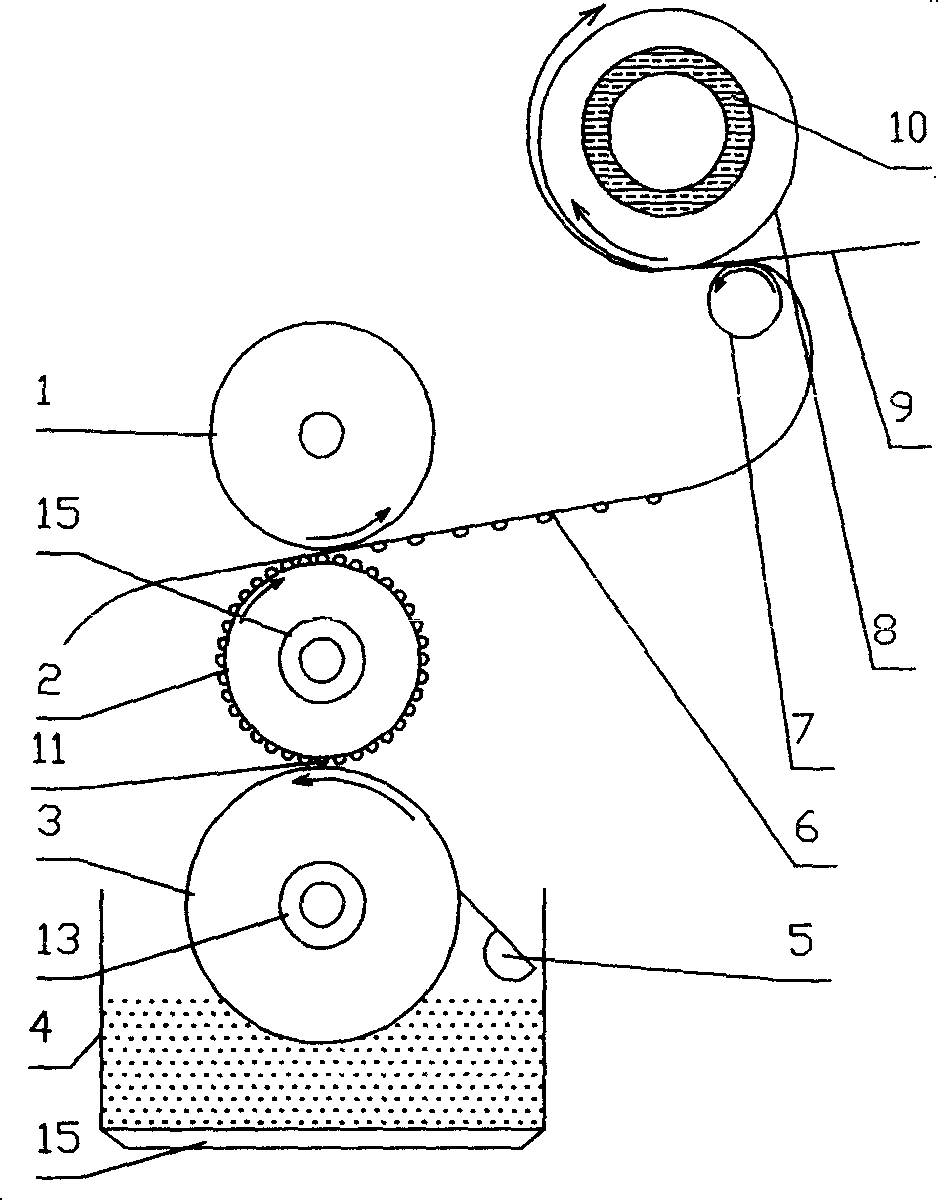

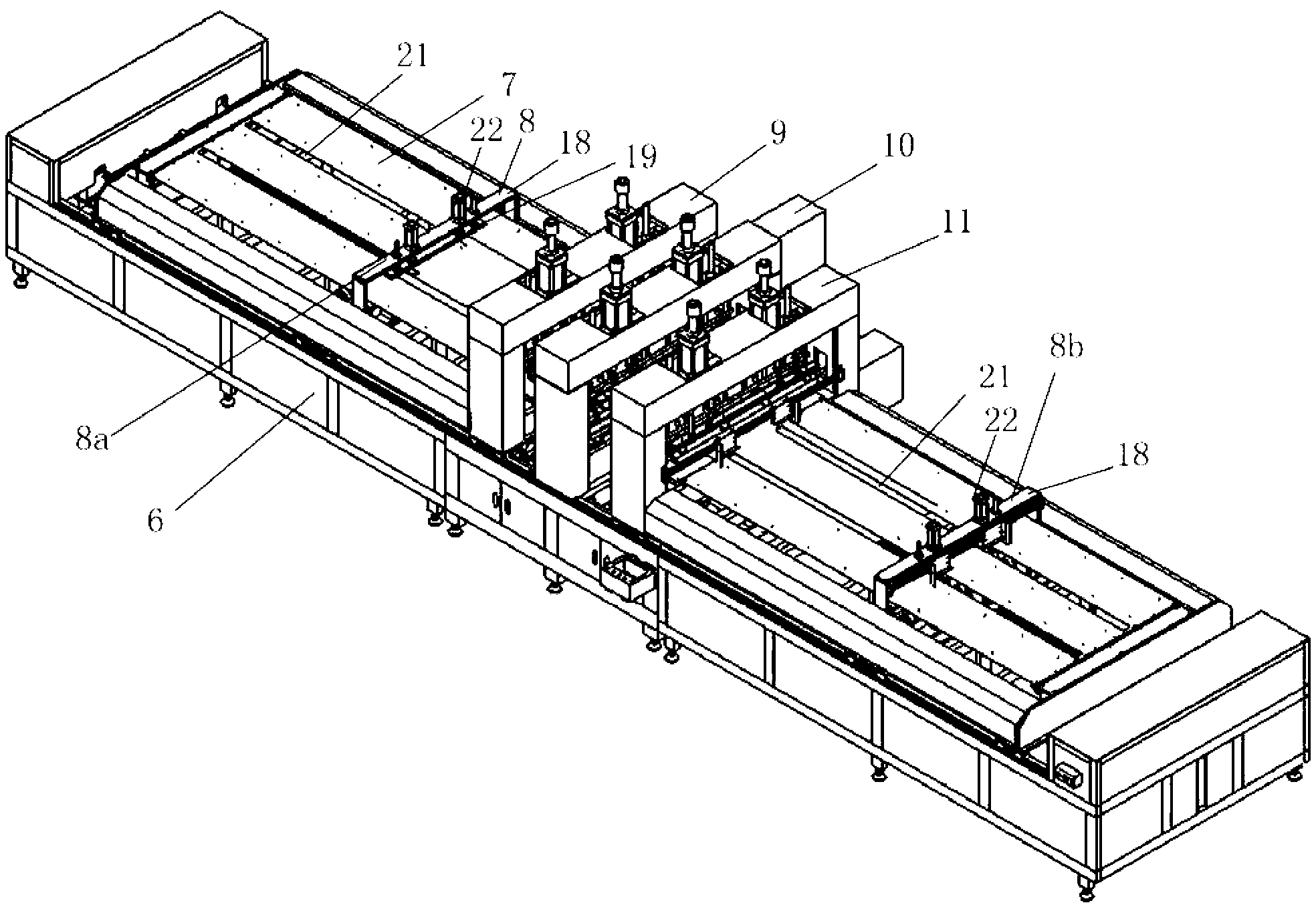

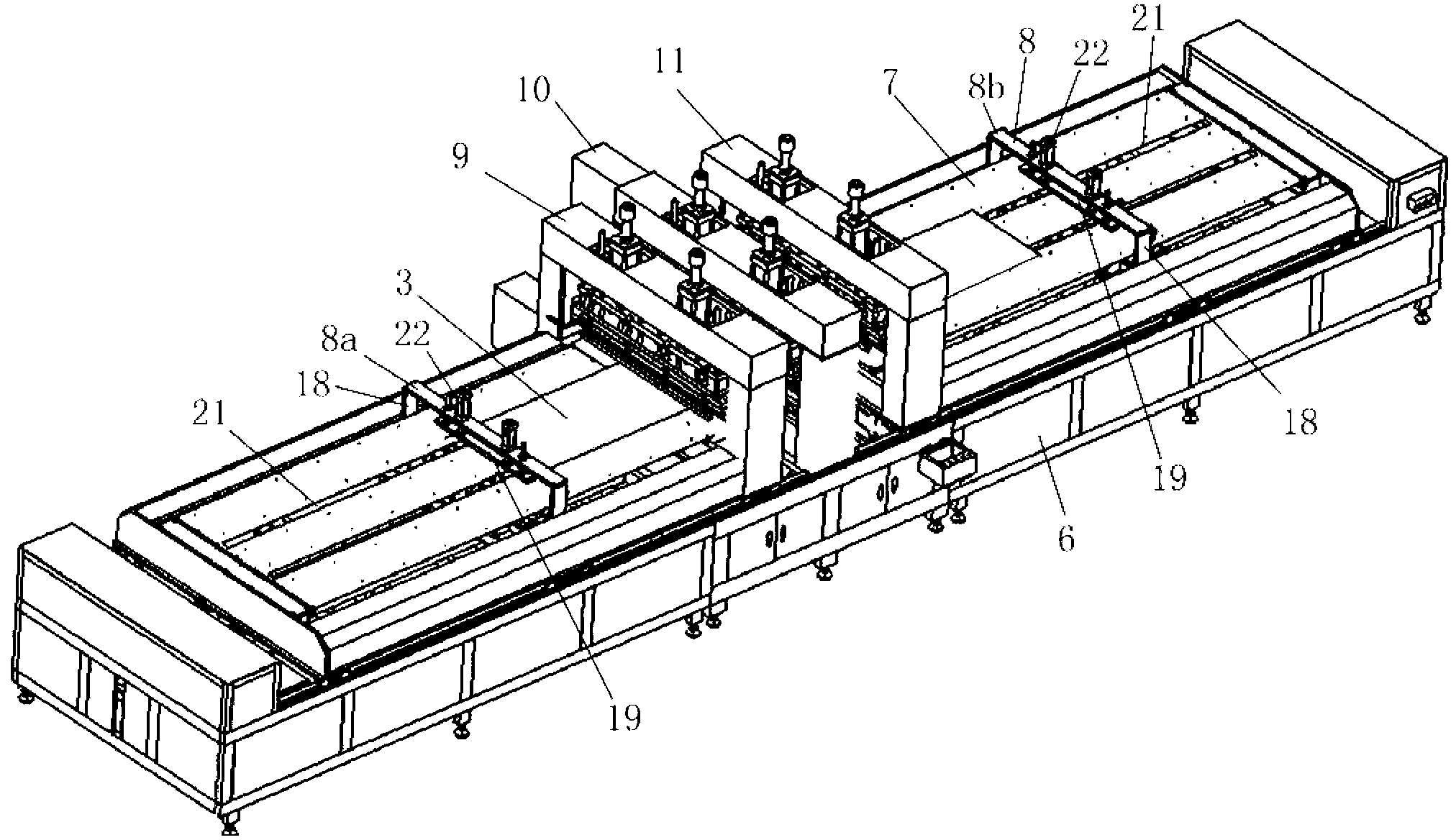

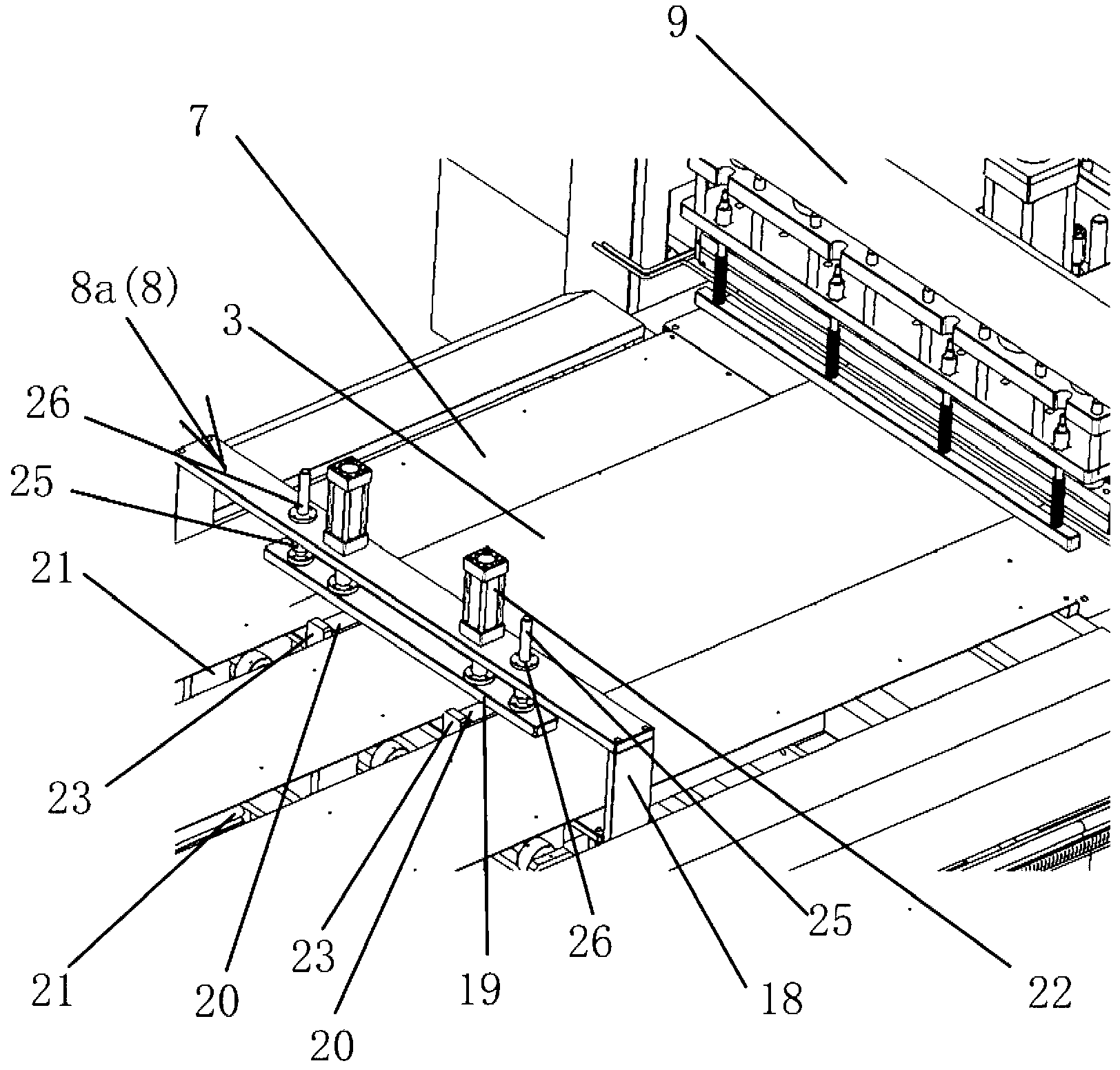

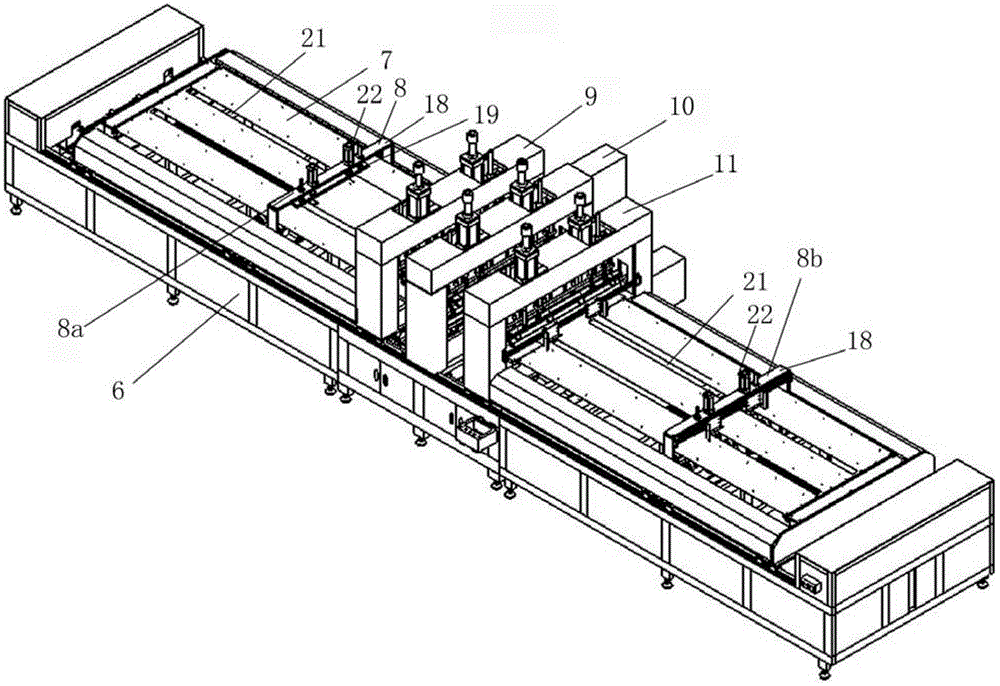

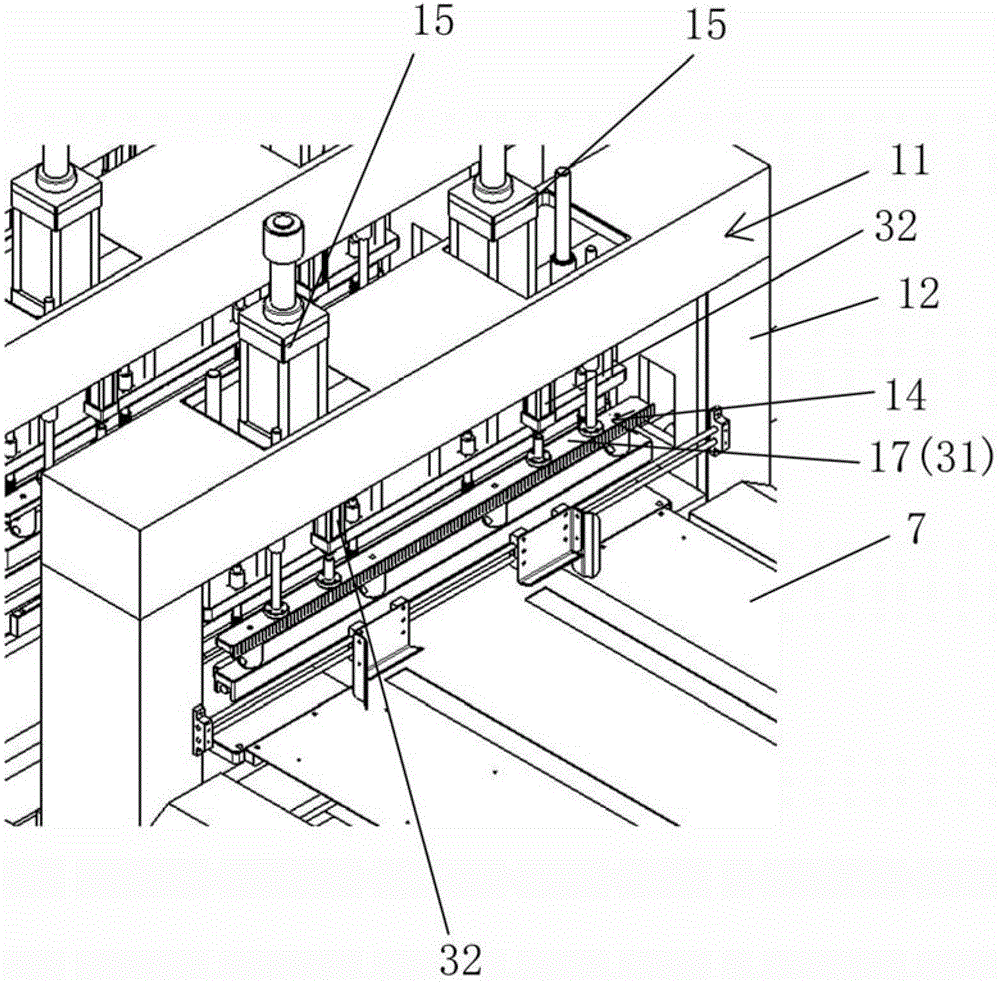

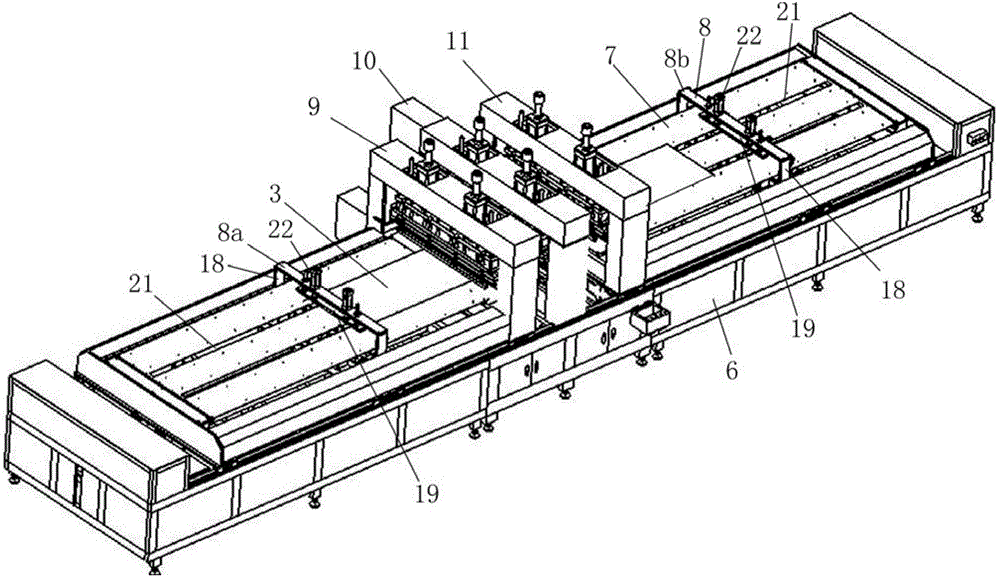

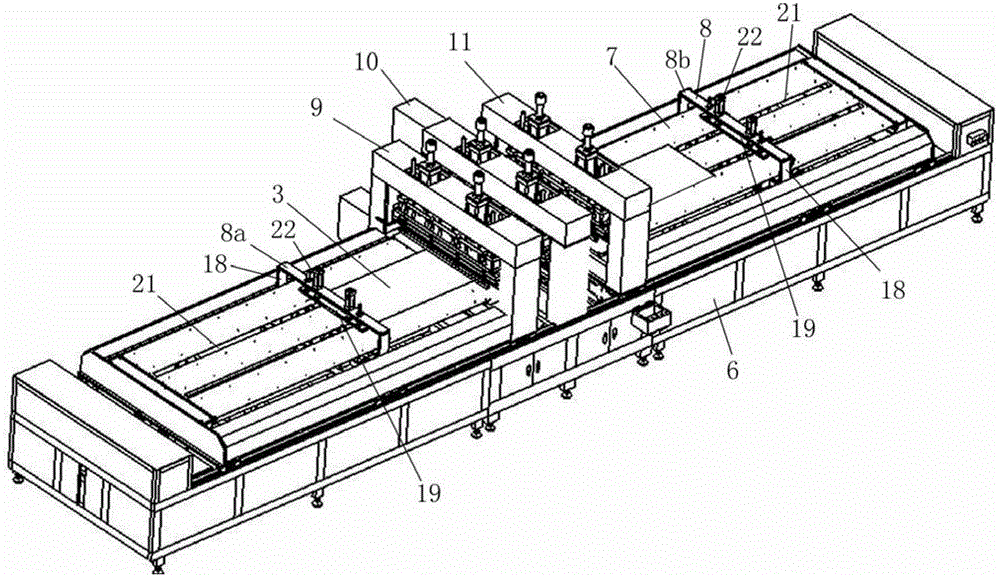

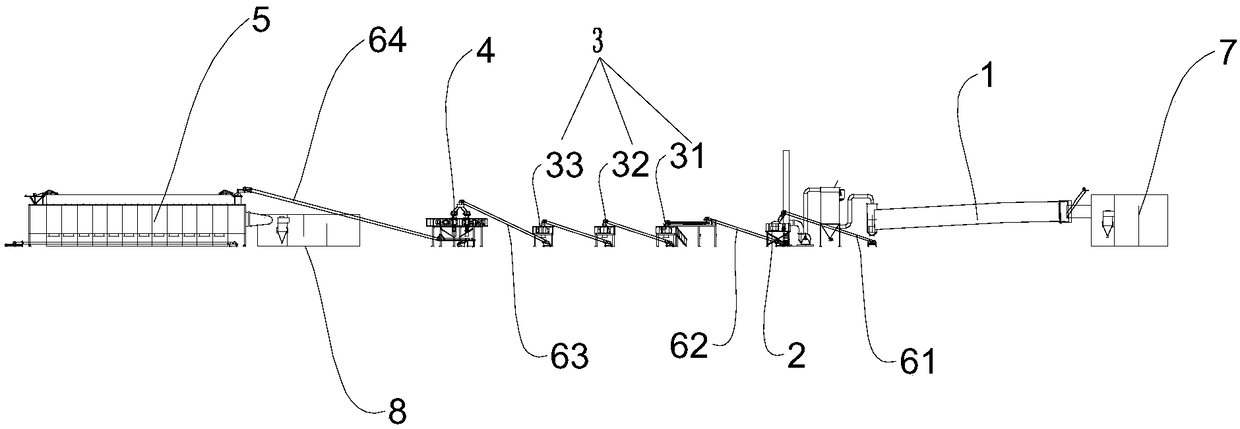

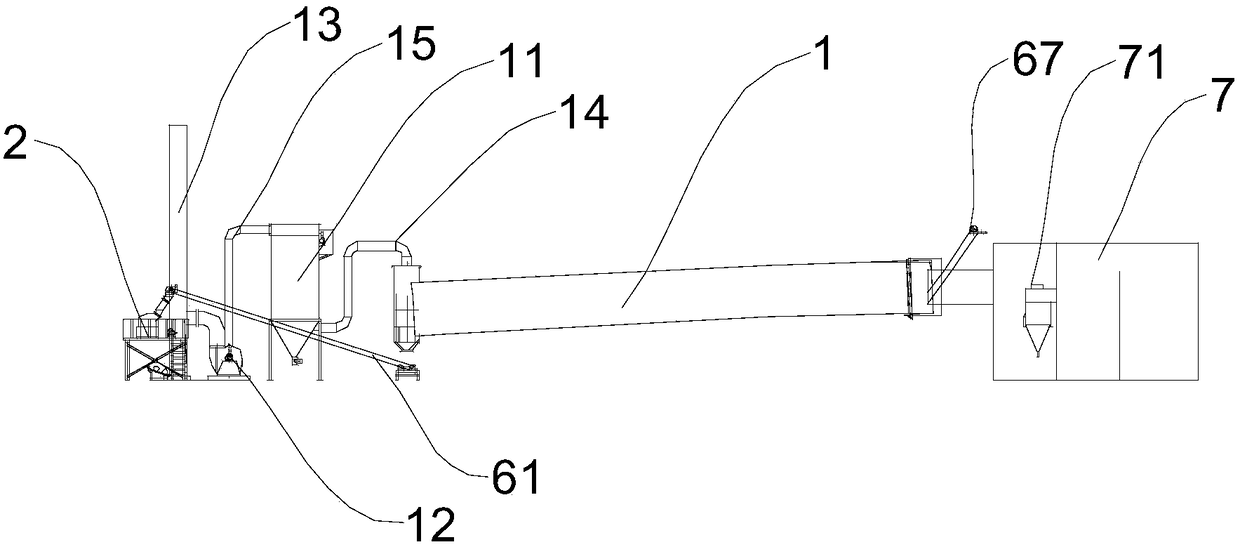

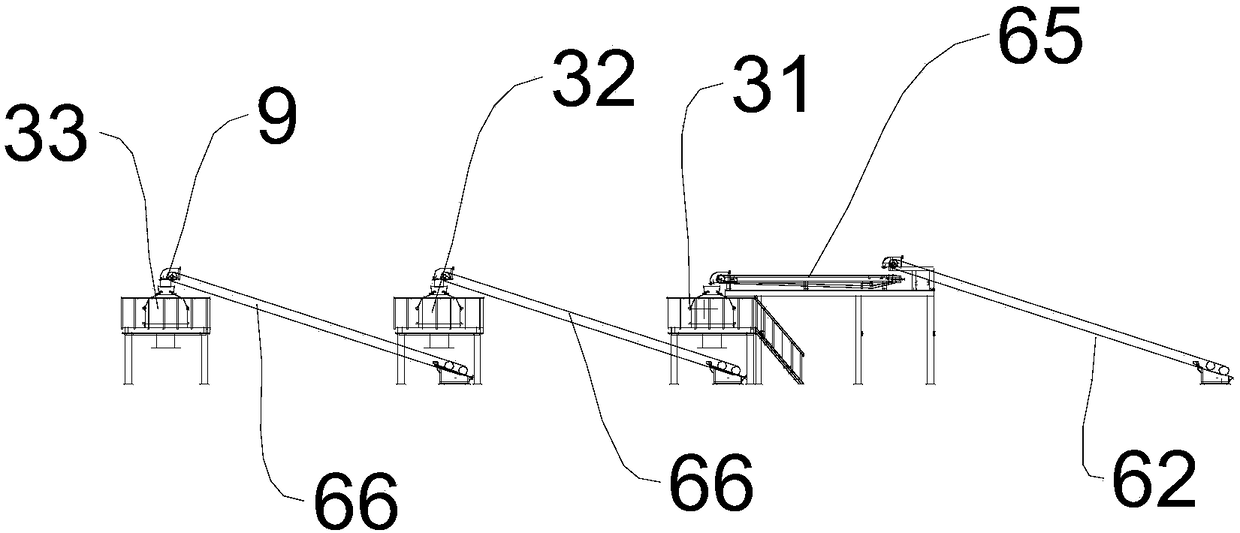

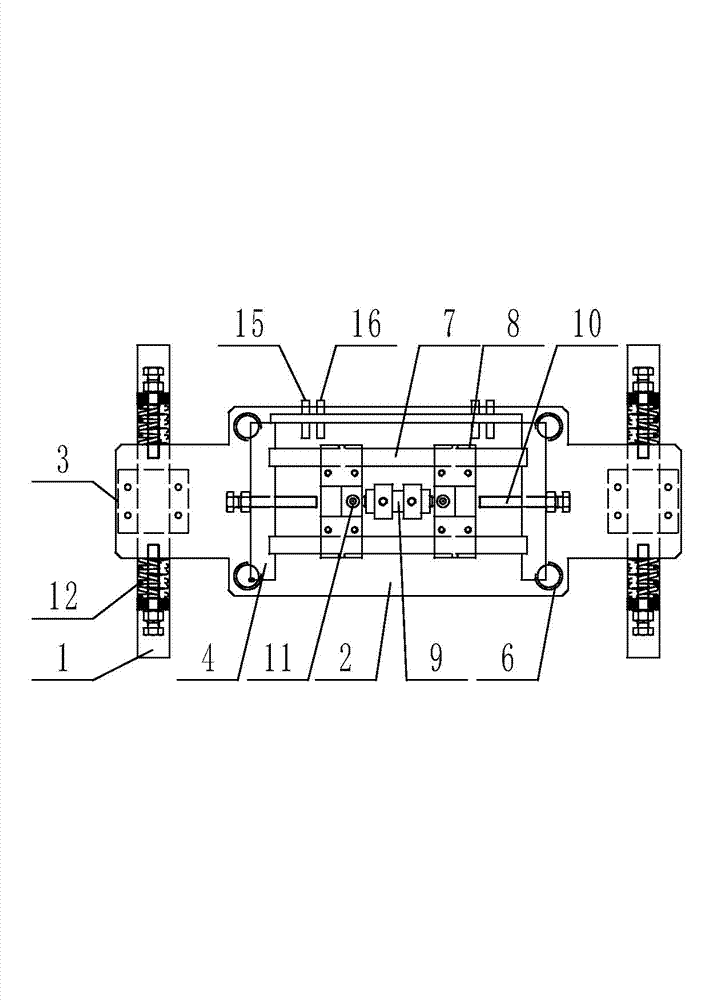

Metallurgy coke breeze molding production equipment and system

PendingCN108504375ANot prone to stickingImprove yieldDispersed particle filtrationCoke ovensHot blastMaterial transport

The invention relates to the technical field of coke molding, and discloses metallurgy coke breeze molding production equipment and system. The metallurgy coke breeze molding production equipment comprises a raw material drier, a first material transport assembly, a pulverizer, a second material transport assembly, a mixing adherence mechanism, a third material transport assembly, a pressing finished product mechanism, a forth material transport assembly and a finished product material drying box which are arranged in sequence; the raw material drier is connected with a raw material hot blastheater; and the finished product material drying box is connected with a finished product material hot blast heater. The metallurgy coke breeze molding production equipment and system have the advantages of high production efficiency, large production and high finished product ratio.

Owner:青岛华煤能源科技有限公司 +1

A mold and production equipment for preparing foam sandwich panels

Owner:HEBEI UNIV OF TECH

Lower blowing device in respiration hood production line

The invention relates to a lower blowing device in a respiration hood production line. The lower blowing device comprises two guide rails arranged on an opening and closing mold bracket and a front and back moving plate; slide blocks are arranged at the lower parts of two ends of the front and back moving plate; the slide blocks are connected with the guide rails; return springs are arranged on the guide rails positioned at two sides of the slide blocks; an up and down moving plate is arranged above the front and back moving plate; an up and down cylinder is vertically arranged in the front and back moving plate; the cylinder body of the up and down cylinder is connected with the front and back moving plate; a telescopic rod of the up and down cylinder is connected with the up and down moving plate; two supporting guide rods are transversely arranged in the up and down moving plate; two supporting slide blocks are arranged on the supporting guide rods; a double-output shaft cylinder is arranged between the two supporting slide blocks; two telescopic rods of the double-output shaft cylinder are connected with the two supporting slide blocks respectively; and blowing pins are arranged above the two supporting slide blocks respectively. The lower blowing device is suitable for the respiration hood production line, is arranged below a die, can improve the work efficiency, and can prevent a blank positioned in the die from being stuck.

Owner:张家港市同创机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com