Lower blowing device in respiration hood production line

A breathing mask and production line technology, applied in the field of air blowing devices, can solve problems such as material sticking in billets, affect work efficiency, and affect product quality, and achieve the effects of improving quality, improving work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The down blowing device in the respirator production line of the present invention will be further described in detail below through specific embodiments.

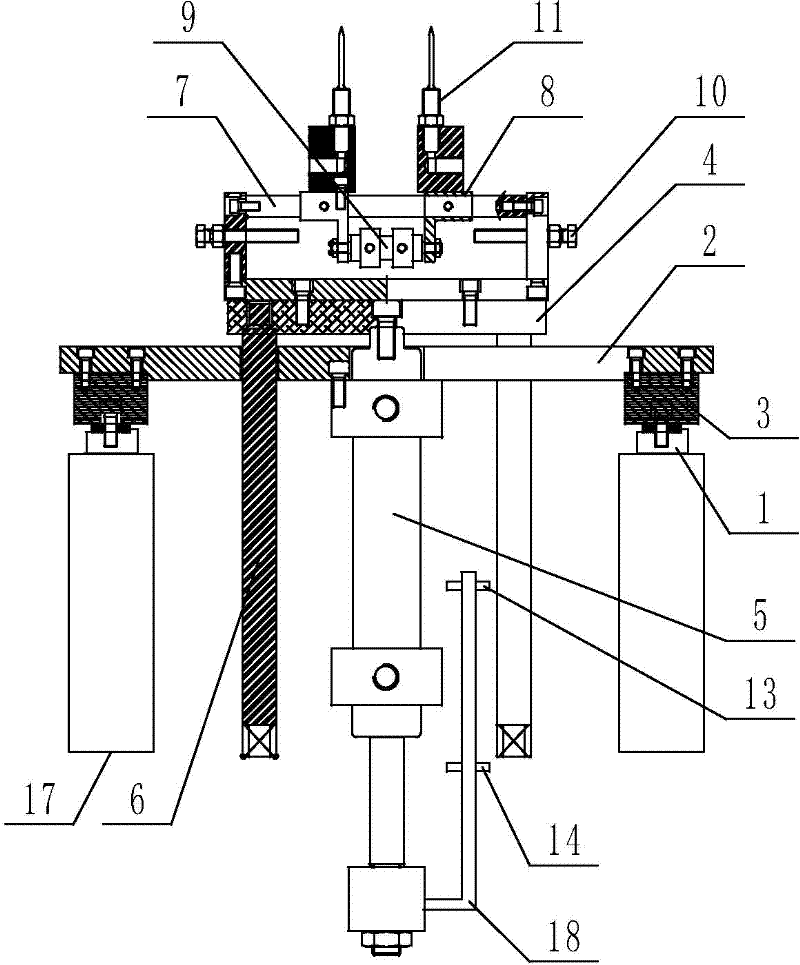

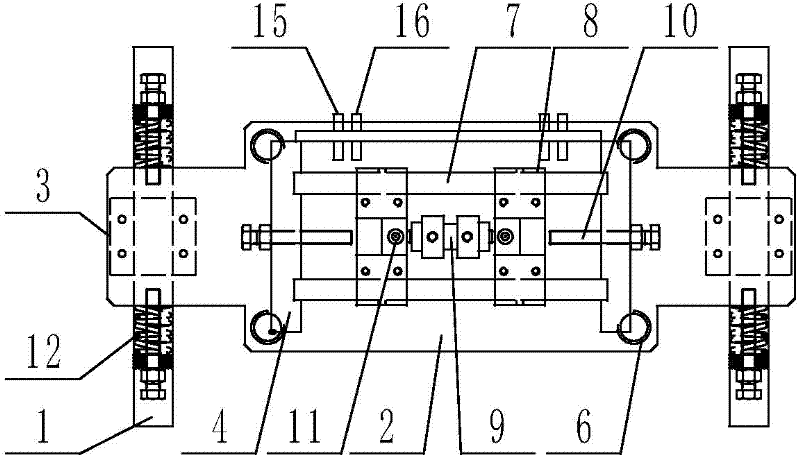

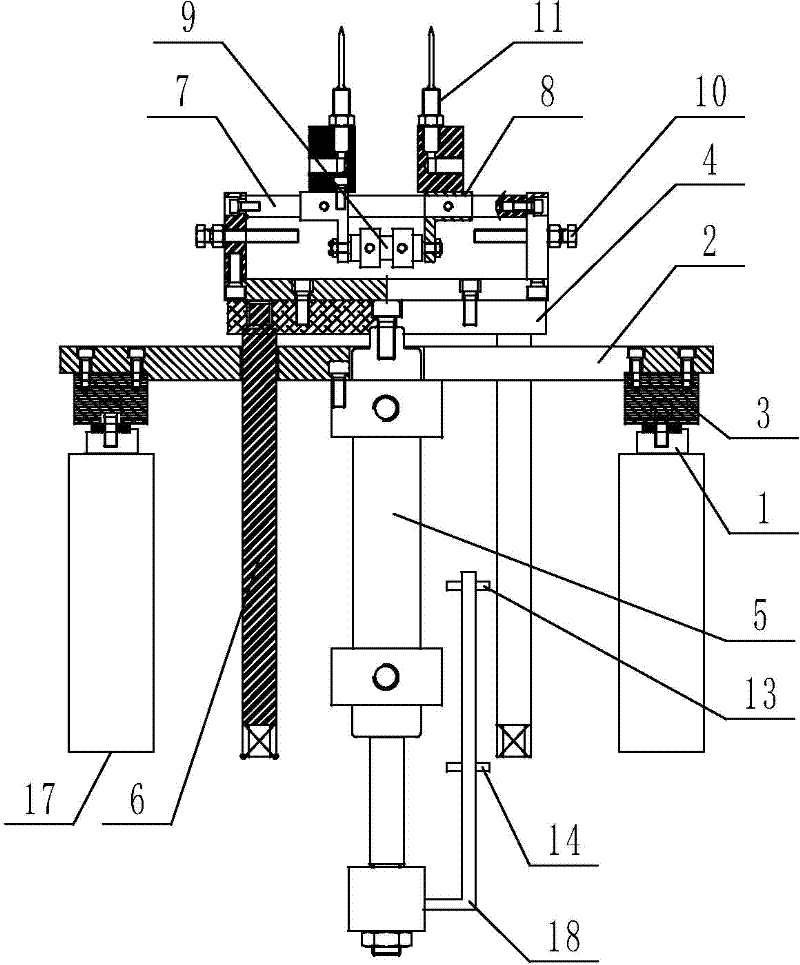

[0014] like figure 1 , figure 2 As shown, the blow-down device in the respirator production line includes two guide rails 1 arranged on the two opening and closing mold brackets 17, and a front and rear moving plate 2 is erected between the two guide rails 1. The lower parts of both ends of the front and rear moving plate 2 The sliders 3 are respectively provided, the sliders 3 are connected with the guide rails 1, the guide rails 1 located on both sides of the slider 3 are respectively provided with return springs 12, the upper and lower moving plates 4 are arranged above the front and rear moving plates 2, and the front and rear moving plates 2 The upper and lower cylinders 5 are vertically arranged in the middle, the cylinder bodies of the upper and lower cylinders 5 are connected with the front and rear moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com