Side intake duct oil-gas separator for engine

A technology of oil and gas separator and side air intake, which is used in engine components, machines/engines, mechanical equipment, etc., can solve the problems of reduced filtration efficiency, filter cotton falling off, loss of filtration function, etc., to achieve high oil and gas separation efficiency, use Good stability and the effect of reducing injection defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

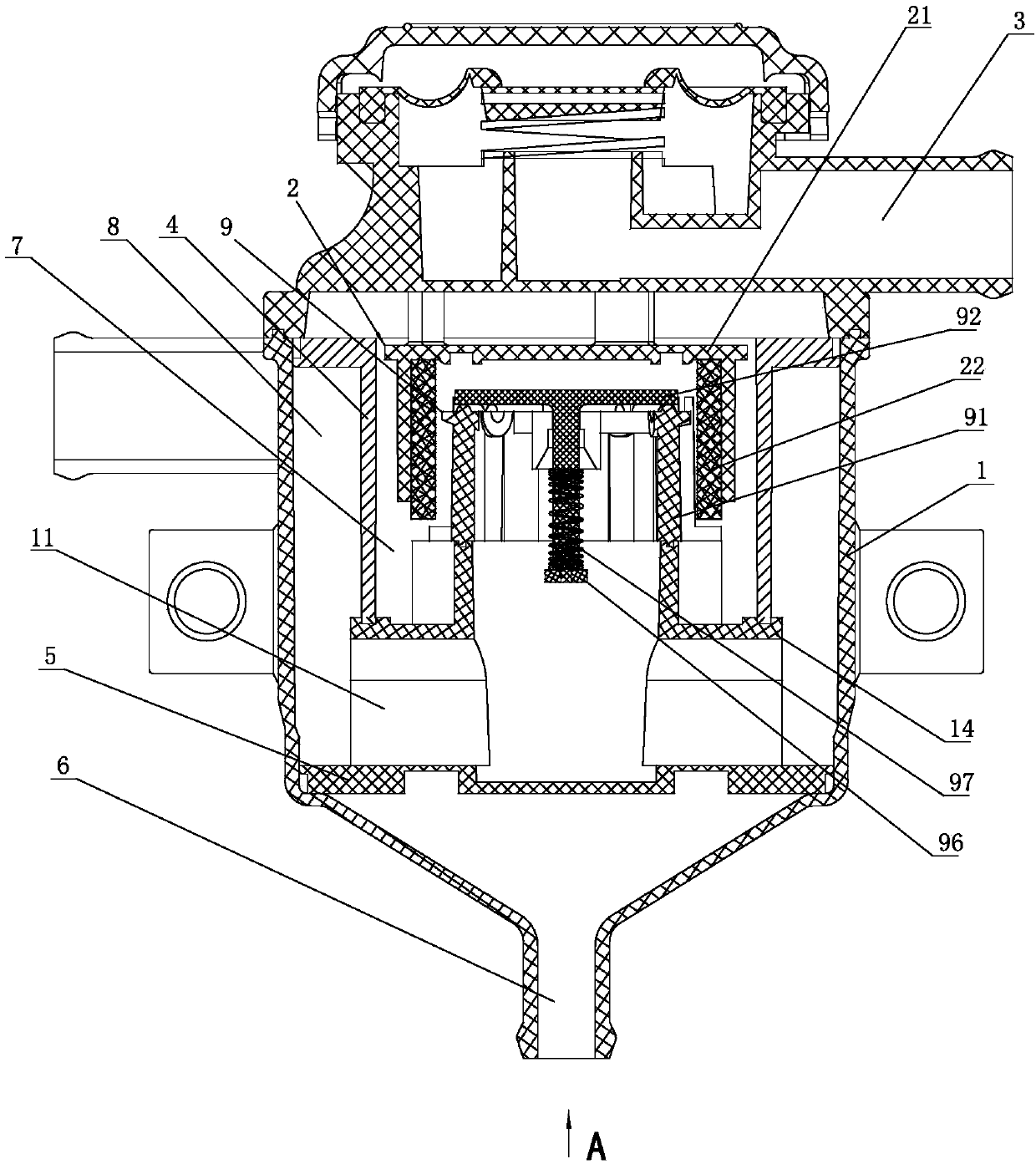

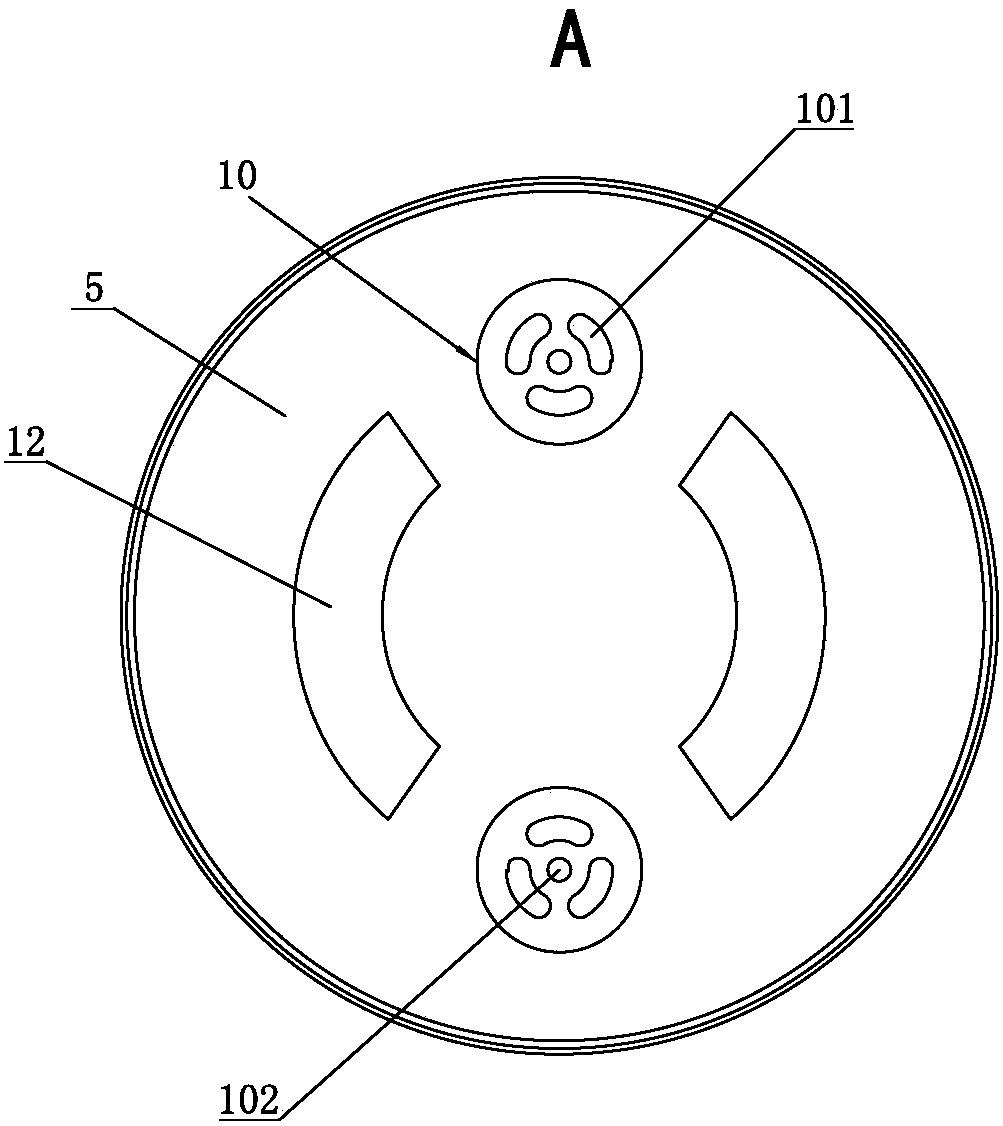

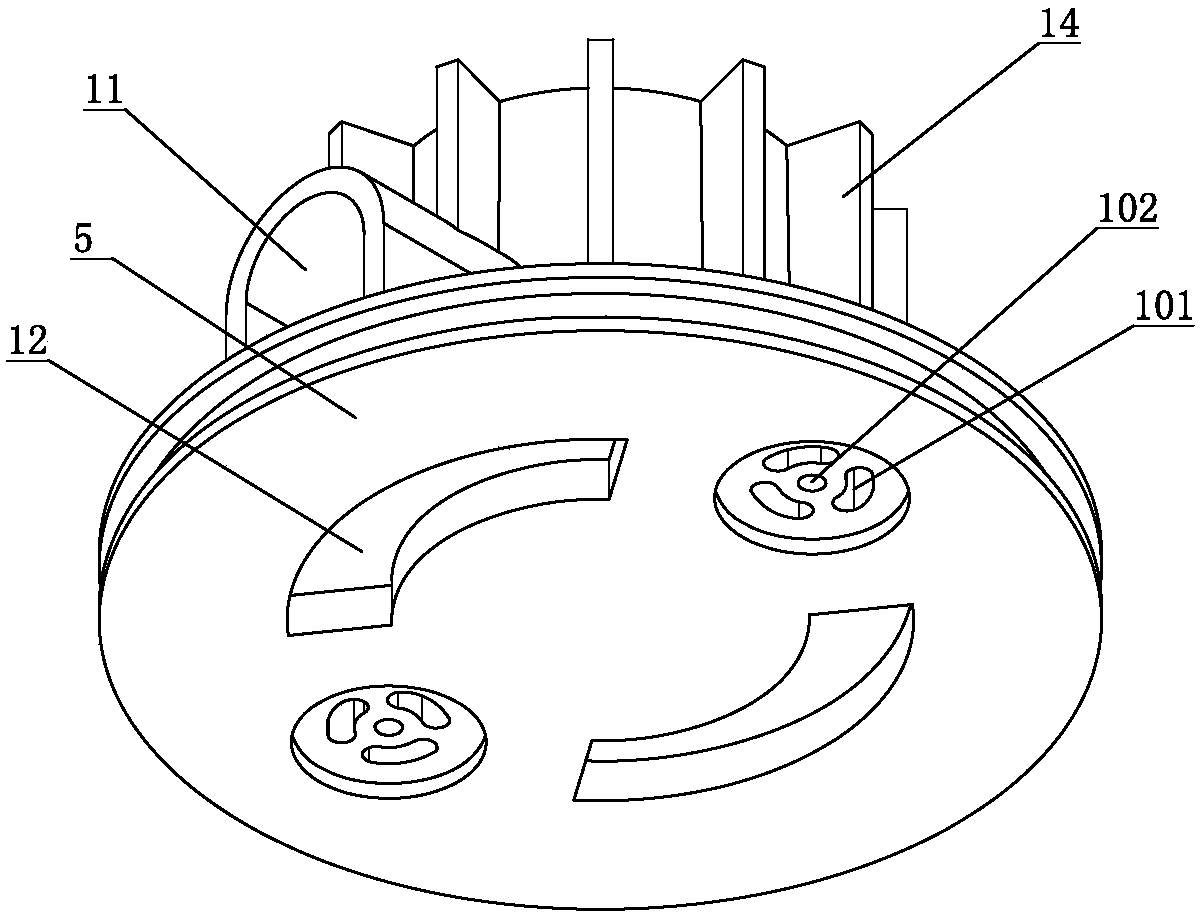

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8As shown, the present invention provides a kind of engine side intake oil-air separator, and it comprises housing 1 and filter element 2 (also comprises other components of course, but because the invention point that does not relate to the invention of the present invention, so no longer repeat them here ), the housing 1 is divided into upper and lower parts, which is convenient for the injection molding of the housing 1 after being set up in this way, and the upper and lower parts are welded to form the housing 1, and the air inlet is located on the side of the upper end of the housing 1 and communicates with the spiral separation chamber 8 , the shell 1 is provided with an air outlet 3, a separation seat 4, a base 5 and an oil r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com