Membrane method oil and gas recovery group control device and using method thereof

A control device, oil and gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as large oil flow and oil and gas flow fluctuations, and achieve the effect of improving oil and gas separation efficiency and avoiding abnormal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Taking a certain oil depot as an example below, the present invention will be described in further detail.

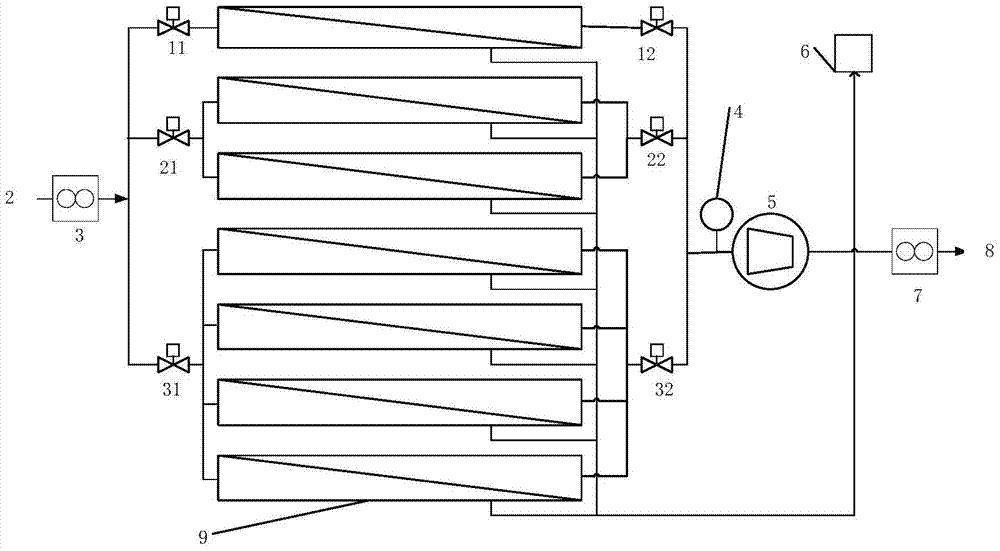

[0032] There are 7 gasoline cranes in the oil depot, and the oil flow of each crane is 80m 3 / h, according to the design principle of the present invention, 7 membrane modules can be selected to process oil and gas, and the processing capacity of each membrane module can be 80*1.2=96m 3 / h design, the membrane module is divided into three groups, namely, a membrane module group composed of 1 rubber state membrane module, a membrane module group composed of 2 rubber state membrane modules connected in parallel, and a membrane group composed of 4 rubber state membrane modules connected in parallel Module groups, the intake side and permeation side of each group are controlled by valves. The permeation side of the membrane module is connected to a vacuum pump to change the pressure difference in the rubbery membrane module. , and use frequency converter for frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com