Crystal catcher applied to acid anhydrides

A trap and crystal technology, applied in the field of crystal collection devices, can solve the problems of high environmental protection pressure, high energy consumption, high labor intensity, etc., and achieve enhanced heat exchange area, high material yield, and low labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

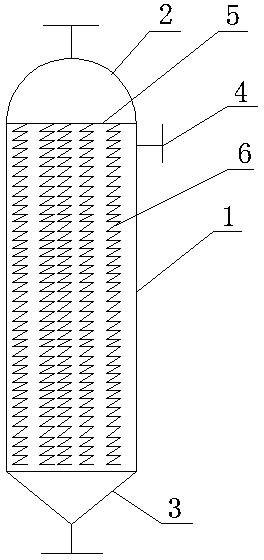

[0011] Such as figure 1 As shown, the present invention is provided with a cylindrical housing 1, the upper end of the housing 1 is sealed and connected with a spherical upper head 2, the lower end is sealed and connected with a conical lower head 3, and the upper end 2 is provided with a treatment liquid inlet. The lower end of the lower head 3 is provided with a crystal outlet. At least one nitrogen inlet 4 is connected to the side wall of the casing 1 .

[0012] Weld and fix the mesh connecting frame 5 on the upper end surface of the housing 1, hang a number of springs 6 evenly in the housing 1 below the connecting frame 5, and the length of each suspended spring 6 is the same as the length of the housing 1 , The lower ends of each spring 6 are respectively free ends that can swing freely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com