Method and device for preparing micro-nano gradient structure on surface layer of metal component

A technology of gradient structure and metal components, which is applied in the field of preparing micro-nano gradient structure, can solve the problems of difficulty in meeting the needs of industrial production, low efficiency of nanometerization of the surface of metal materials, large friction surface strain and strain rate, etc., and achieve good controllability Performance and operability, low cost and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

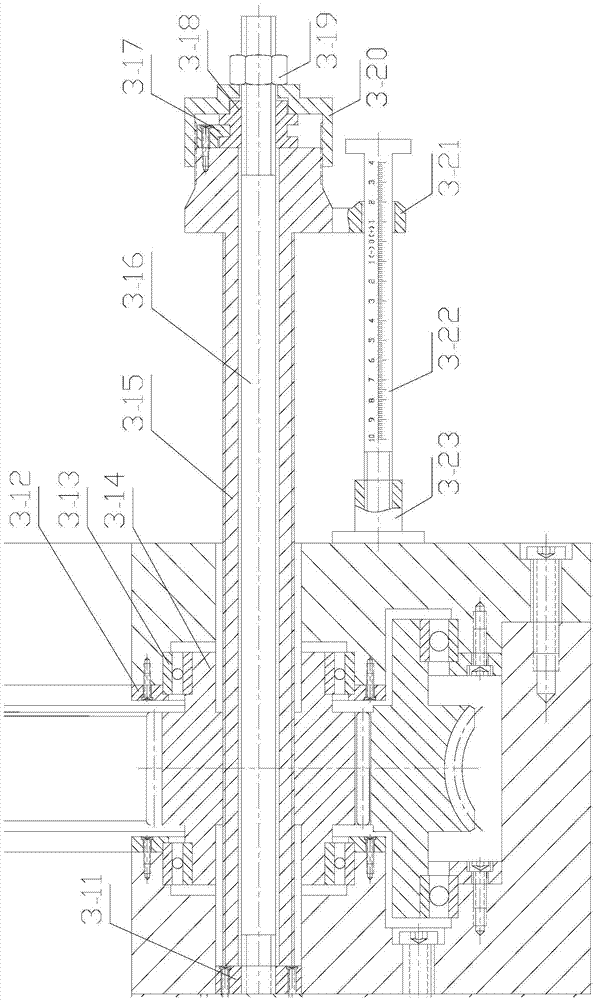

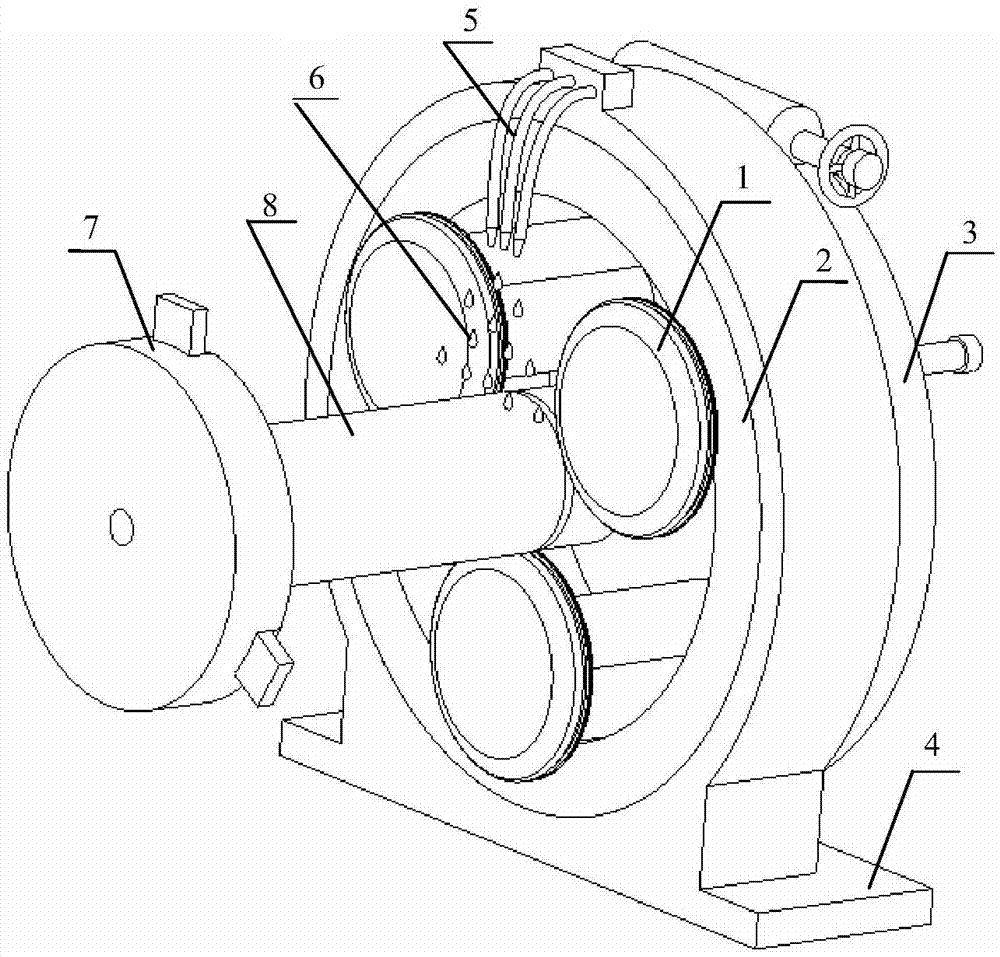

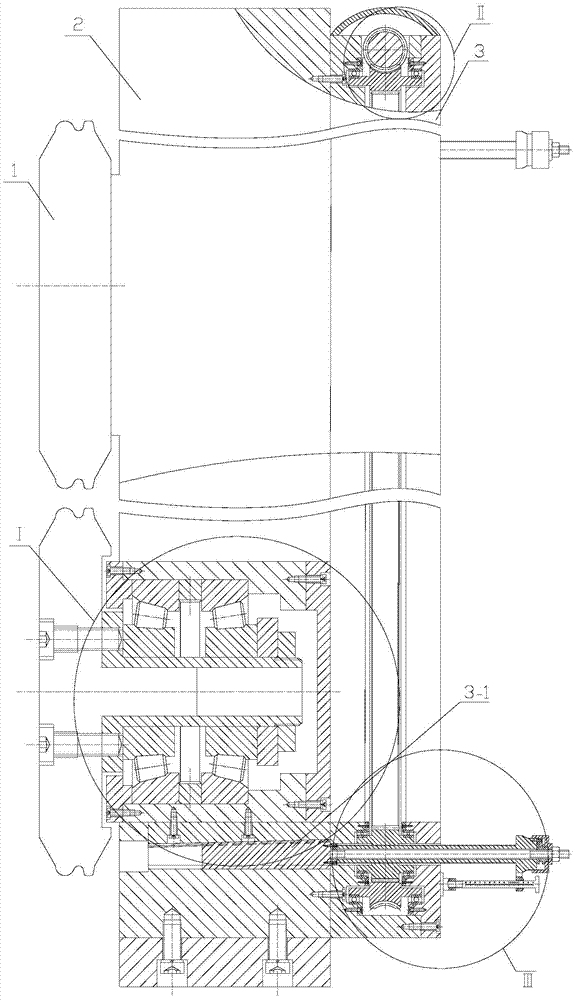

[0092] Adopting the plastic deformation technology of rotary rolling (spinning) of the present invention, the No. 20 steel shaft with a diameter of 450mm is processed on a large horizontal lathe, the diameter of the roll is 140mm, and the radius of the spherical arc of the deformation section of the roll surface is 14mm. The rotation speed of the lathe spindle (component) is 4r / s, the axial feed rate of the roll is 0.48mm / s, the reduction of the roll pass is 0.08mm, the emulsion is used for lubrication and cooling, and the surface of the No. 20 steel shaft is subjected to 6 passes After plastic deformation by spin milling, the surface layer forms a micro-nano gradient structure with a thickness of about 960 μm, and the surface layer is a nano-structure with a size less than 100 nm.

Embodiment 2

[0094] Adopting the plastic deformation technology of spinning rolling (spinning) of the present invention, the ZnAl alloy bar material with a diameter of 200mm is processed on a large horizontal lathe, the diameter of the roll is 80mm, and the radius of the spherical arc of the deformation section under pressure on the roll surface is 6mm. The rotational speed of the lathe spindle (component) is 14r / s, the axial feed rate of the roll is 1.68mm / s, the reduction of the roll pass is 0.06mm, and the emulsion is used for lubrication and cooling, and the surface of the ZnAl alloy bar is subjected to 8 passes After plastic deformation by spin milling, the surface layer forms a micro-nano gradient structure with a thickness of about 600 μm, and the surface layer is a nano-structure with a size less than 100 nm.

Embodiment 3

[0096] Adopting the plastic deformation technology of rotary rolling (spinning) of the present invention, the Monel400 thick-walled pipe with an outer diameter of 360mm and a thickness of 40mm is processed on a large horizontal lathe. The radius of the arc is 10mm, the rotational speed of the lathe spindle (component) is 6r / s, the axial feed rate of the roll is 0.24mm / s, the reduction of the roll pass is 0.04mm, and the emulsion is used for lubrication and cooling. After 10 times of plastic deformation of the outer surface, a micro-nano gradient structure with a thickness of about 400 μm is formed on the surface layer, and the surface layer is a nano-structure with a size less than 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com