Technology for removing defects of connection thread of petroleum drilling tool

A thread and drilling tool technology, which is applied in the field of processing to eliminate the thread defects of oil drilling tools, can solve the problems of insufficient processing technology, low surface hardness, easy bonding, etc., and achieve the reduction of wear, prolongation of life, and improvement of product surface hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

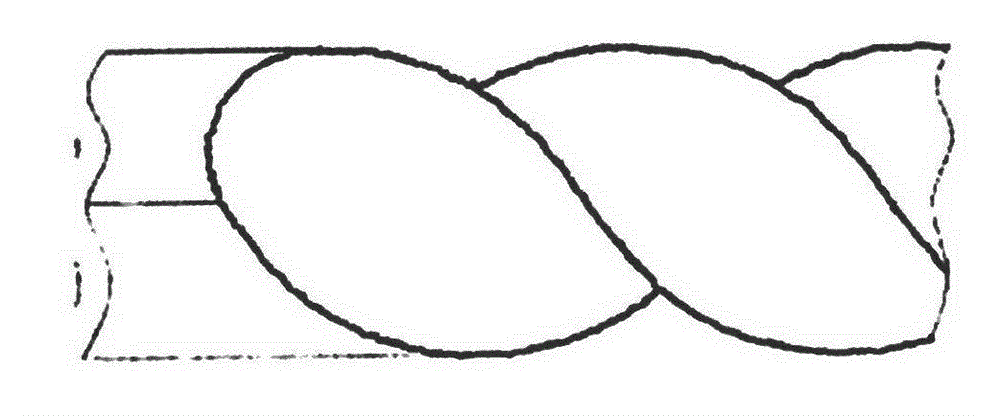

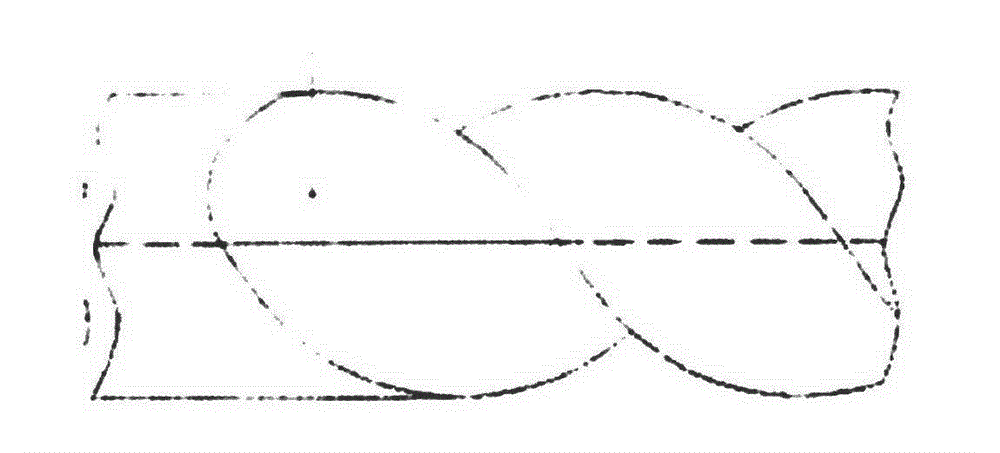

[0014] The specific method is: use the laser to scan the surface hardened oil drilling tool surface where the hardness needs to be increased, and use the high temperature of the laser to quickly dissolve and condense the metal surface, so that the crystal grains in the molten metal do not have time to form. To achieve the purpose of refining the grain, so that the surface of the hardened oil drilling tool has good hardness, and the drilling tool itself has good plasticity.

[0015] After laser hardening treatment of the hardened layer on the surface of the drill tool, the hardness increases from unhardened HRC31°C to HRC55°C.

[0016] The oil drilling tool connecting thread defect elimination technology of the present invention is very simple and convenient to manufacture, and can be manufactured according to the drawings shown in the description.

[0017] Except for the technical features described in the description, all are known technologies by those skilled in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com