Mold and production device for preparing foam sandwich panel

A foam sandwich panel and production equipment technology, which is applied in the field of sheet metal processing, can solve the problems of high requirements for metal powder uniformity and purity, the inability to effectively control the size of the surface metal sheet, and the inconsistency of the composition of the metal sheet and the sandwich layer. Guarantee the effect of foam metal foaming rate, high strength and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

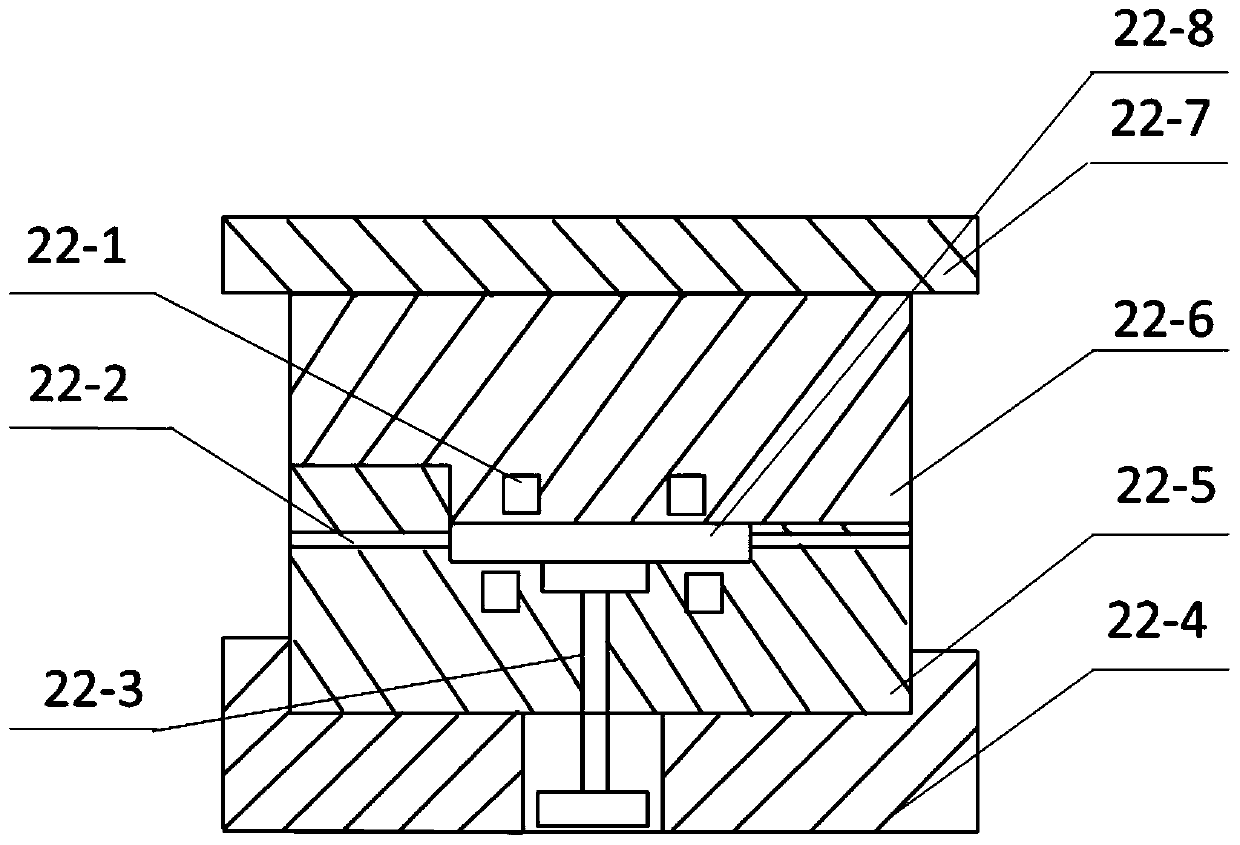

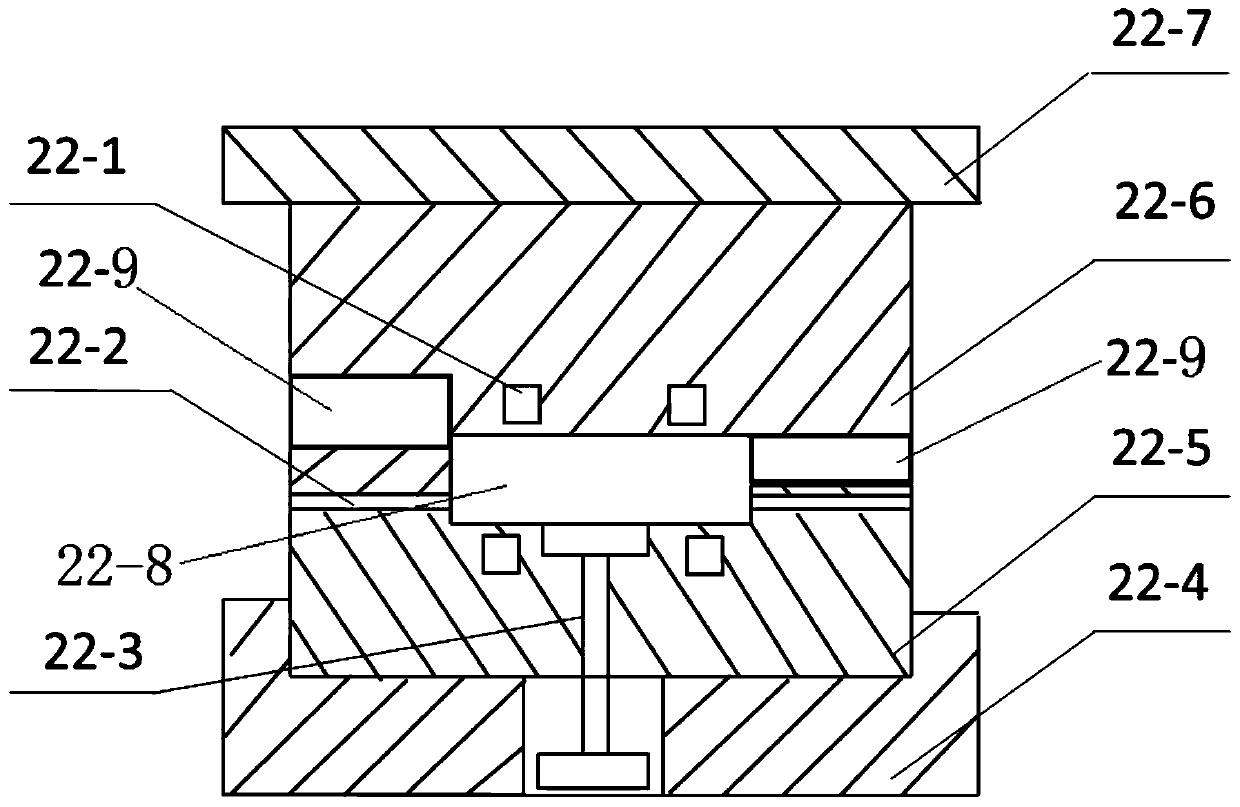

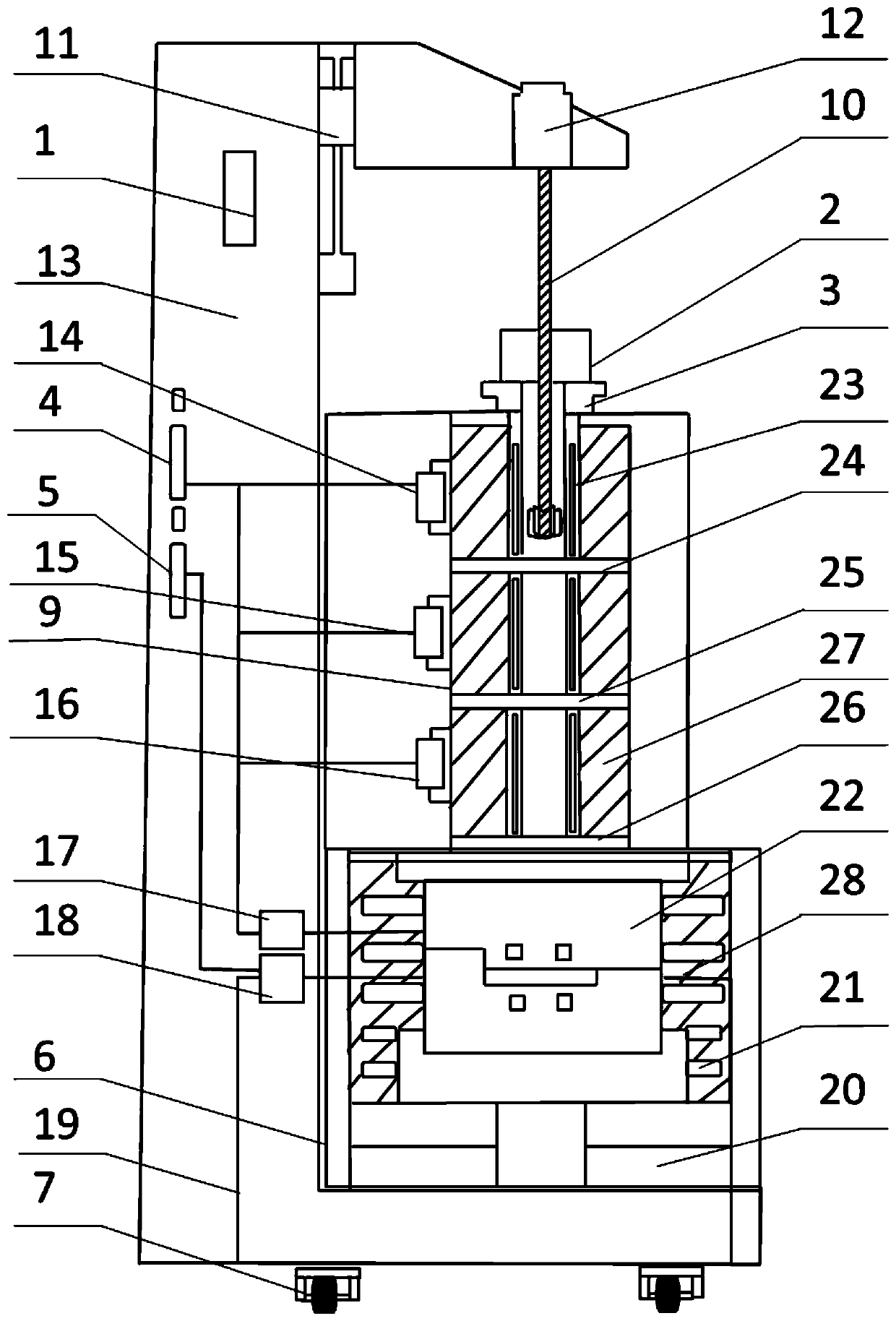

Method used

Image

Examples

Embodiment 1

[0052] First, use the stirring paddle lifting device console 1 to lift the stirring paddle 10 out of the tube furnace cavity 27, raise the temperature of the first temperature zone of the tube furnace cavity 27 to 700°C, and raise the temperature of the second temperature zone to 600°C, The temperature of the third temperature zone is raised to 650°C, and the temperature of the box-type furnace cavity 28 is raised to 650°C. The protective gas is introduced into the box-type furnace cavity 28 through the protective gas inlet hole 8. At this time, the three baffles are pushed into the furnace.

[0053] Put 400g of the aluminum block into the first temperature zone of the tube furnace cavity 27 and keep it warm for 60 minutes. The liquid enters the second temperature zone. After the temperature of the molten aluminum is stabilized, add 0.4% calcium particle tackifier into the second temperature zone of the tube furnace cavity 27, stir for 4 minutes at a speed of 400r / min, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com