Exhaust gas analyzer and probe unit

A technology of exhaust gas analysis and detection unit, which is applied in the direction of analyzing materials, measuring devices, and material analysis through electromagnetic means. It can solve problems such as screw head damage, complicated operations, and screw falling off, so as to improve heat insulation and measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, an embodiment of an exhaust gas analyzer according to the present invention will be described with reference to the drawings.

[0030] The exhaust gas analysis device 100 according to the present embodiment is installed, for example, in an exhaust pipe of a marine engine and is used to analyze a specific component (for example, NO) contained in the exhaust gas flowing therein. x , SO x , C0 2 , CO, etc.) direct plug-in device.

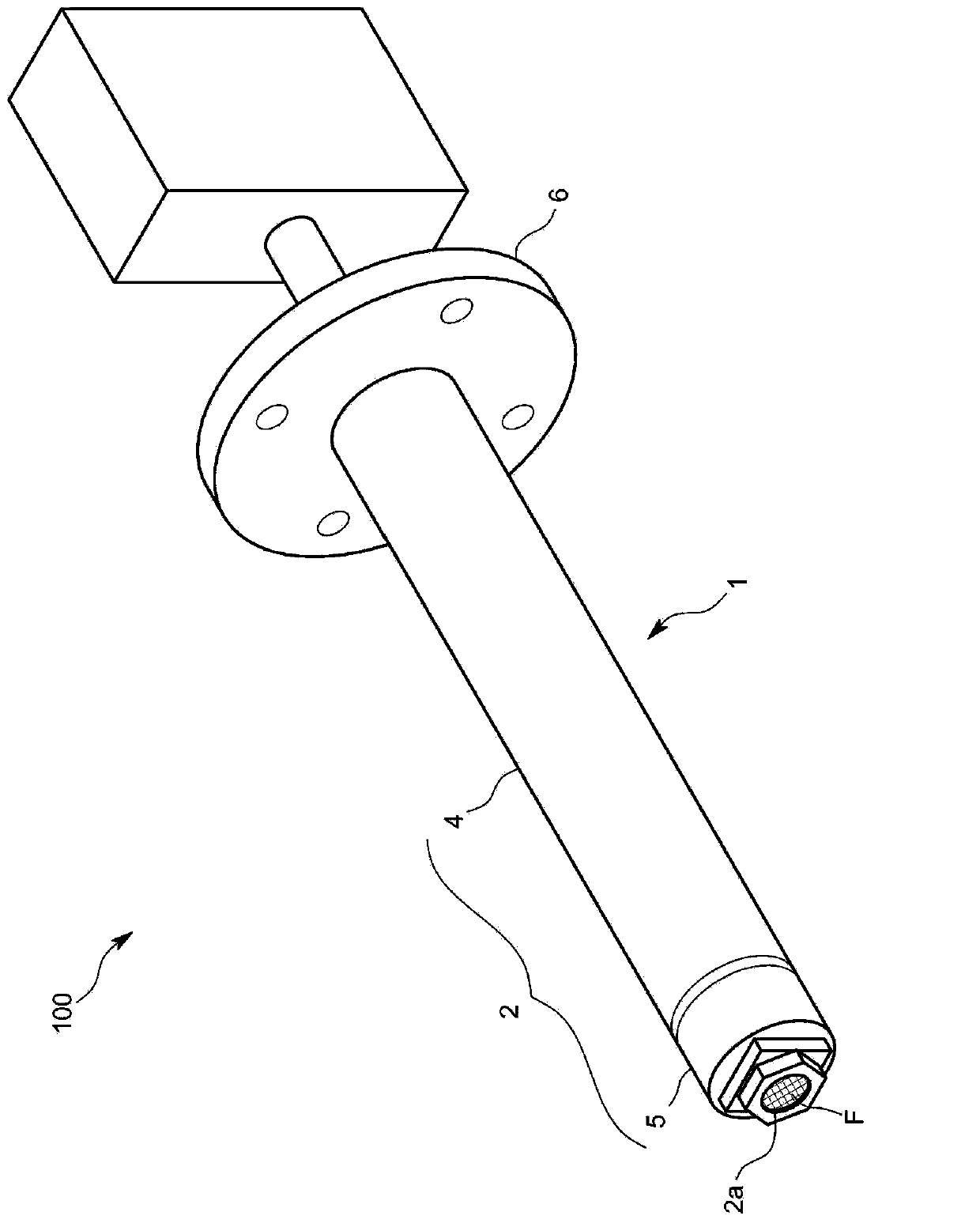

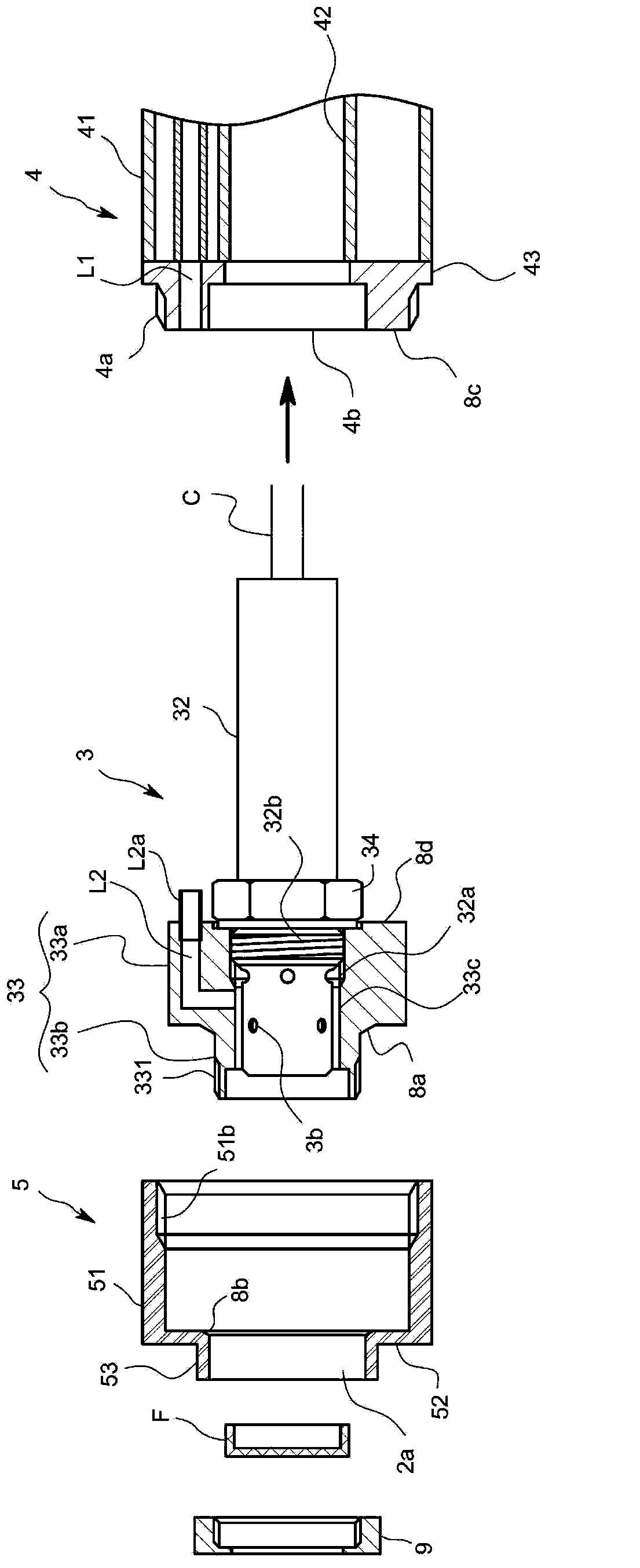

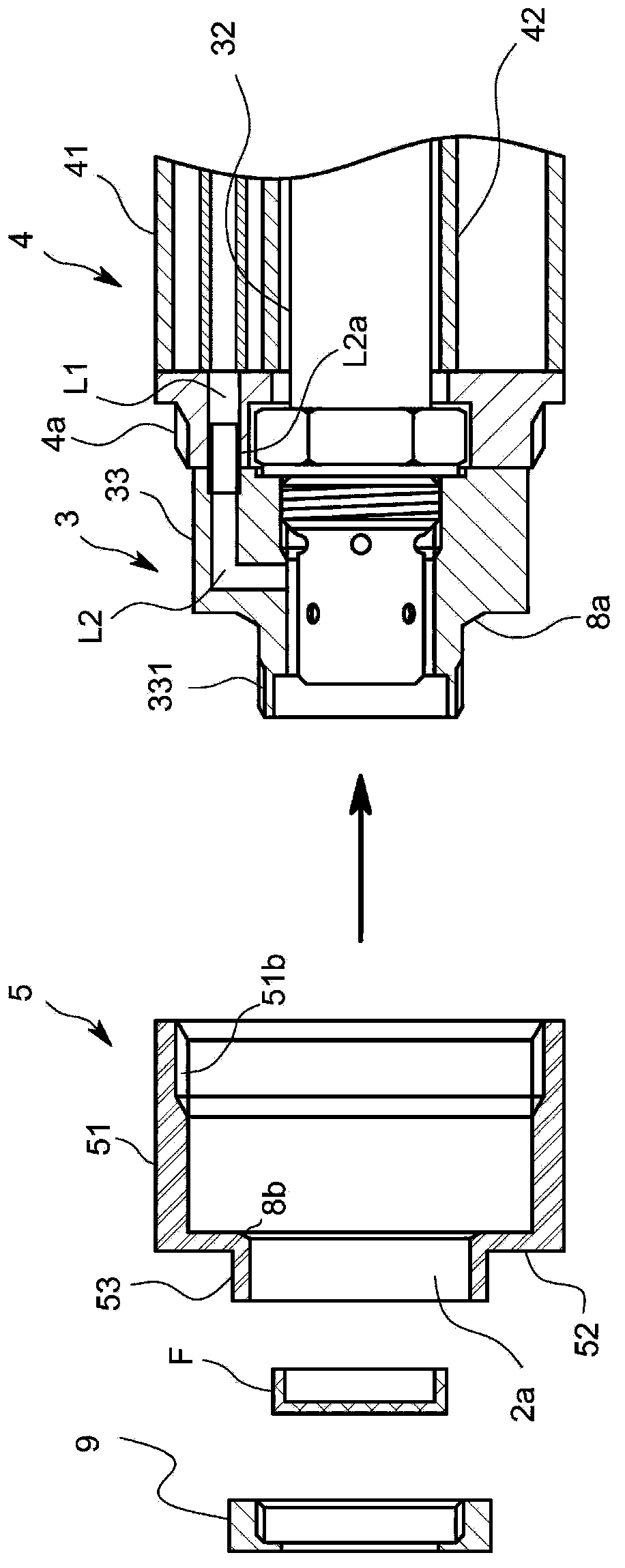

[0031] Specifically, as figure 1 As shown, the device has: a detection unit 1 having a sensor main body 32 for detecting the specific component inside; an analysis unit ( not shown); a flange-shaped mounting portion 6 for fixing to the exhaust pipe. In a state where the exhaust gas analysis device 100 is attached to the exhaust pipe, it is configured such that the front end portion of the detection unit 1 protrudes into the exhaust pipe.

[0032] Since this embodiment is characterized by the detection unit 1 , the detection uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com