Plug for sand control

A technology of plugging and sand control, which is applied in wellbore/well components, sealing/packing, earthwork drilling and production, etc. It can solve the problem of inability to connect the packer, pollute the lower oil layer of the packer, and temporary plugging that cannot be used for sand control, etc. problems, to achieve the effect of facilitating subsequent recycling operations, improving on-site operation efficiency, and avoiding sand jams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

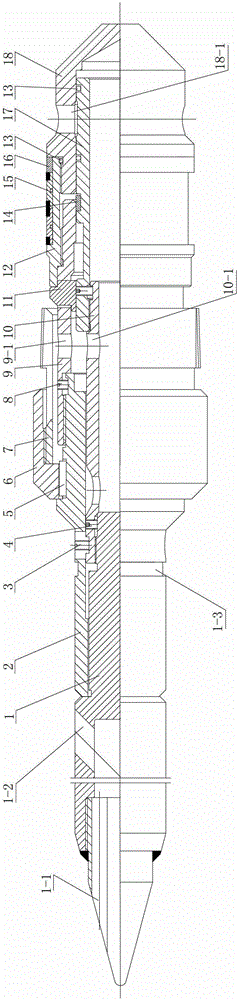

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0023] see figure 1 , a plug for sand control, including a fishing rod 1, an upper mandrel 10 threadedly connected to the fishing rod, a lower mandrel 17 connected to the upper mandrel, and a connection set on the outside of the fishing rod and fixed to the upper mandrel by a shear pin 3 barrel 2. The other end of the upper mandrel is fixedly connected to the lower mandrel by a fastener. In this embodiment, the other end of the upper mandrel is fixedly connected to the lower mandrel by a fixing pin 4 . The outside of the connecting cylinder is sequentially fitted with a centralizing sleeve 6 and a sliding sleeve 9 from left to right, and the internal thread of the centralizing sleeve is connected to the elastic claw 7; the sliding sleeve is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com