Rear bearing of motor as well as centrifugal compressor and refrigeration equipment comprising same

A technology of centrifugal compressors and rear bearings, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as oil temperature failure, lubricating oil viscosity drop, oil film dynamic pressure drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

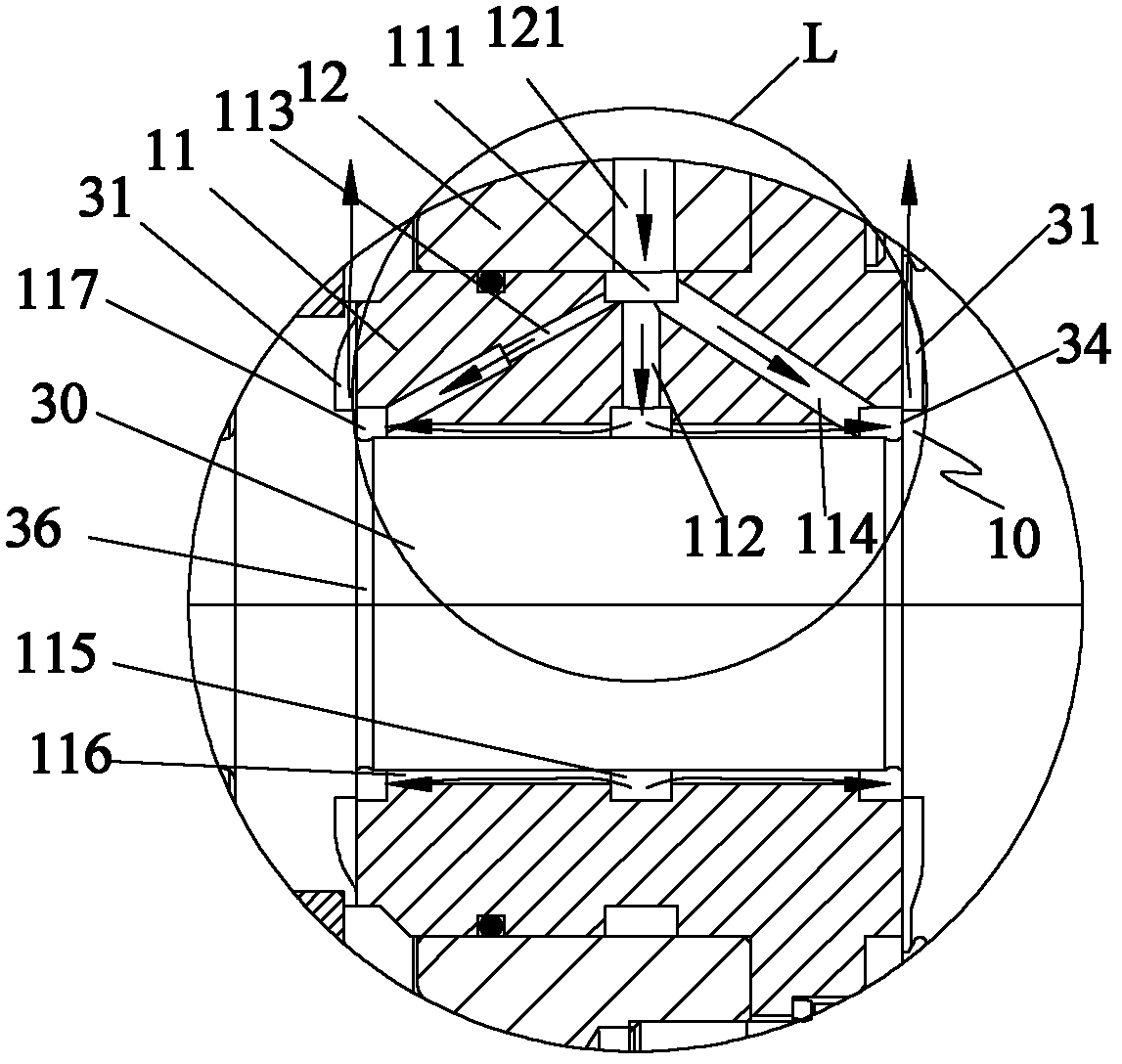

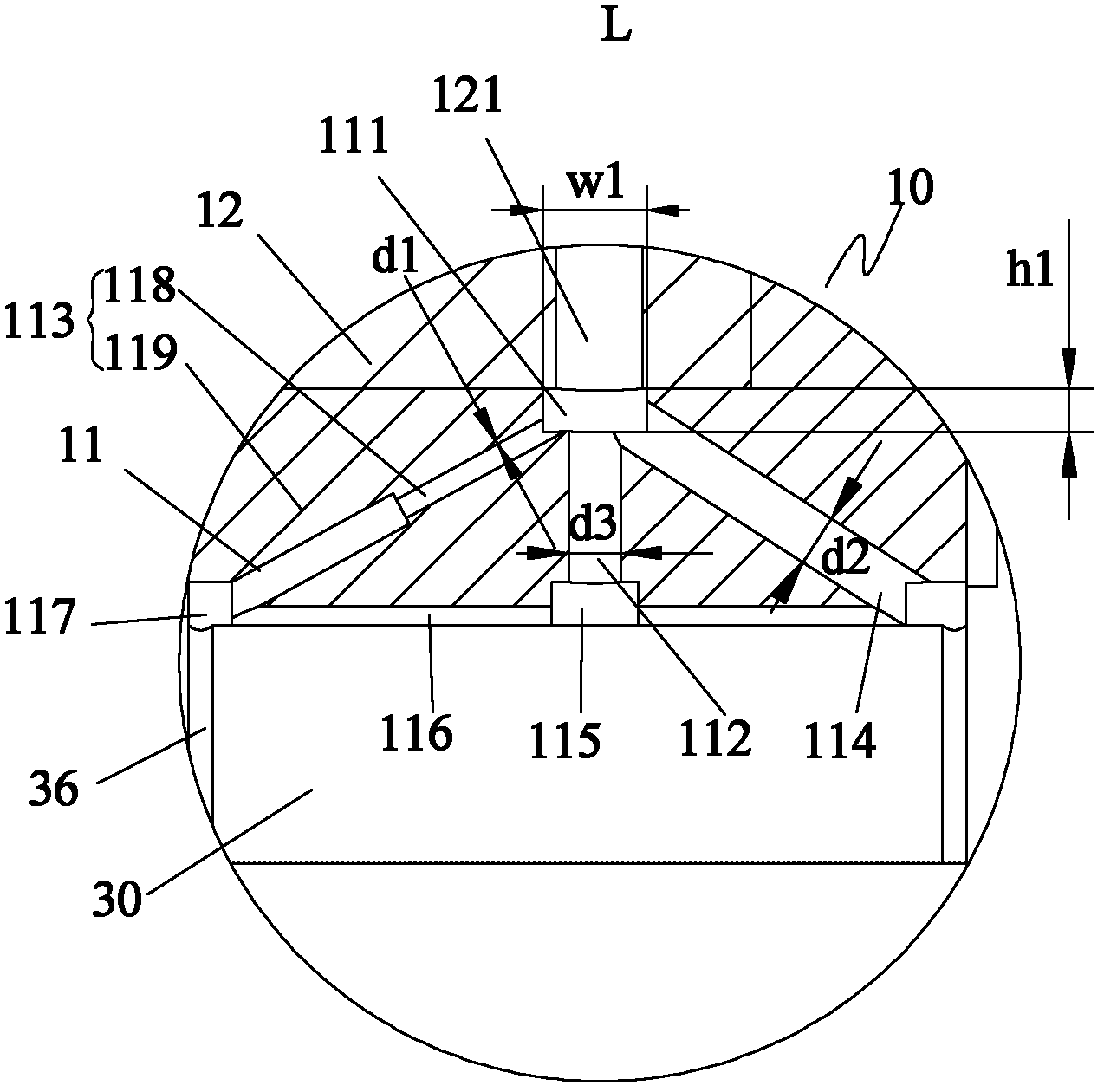

[0031] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

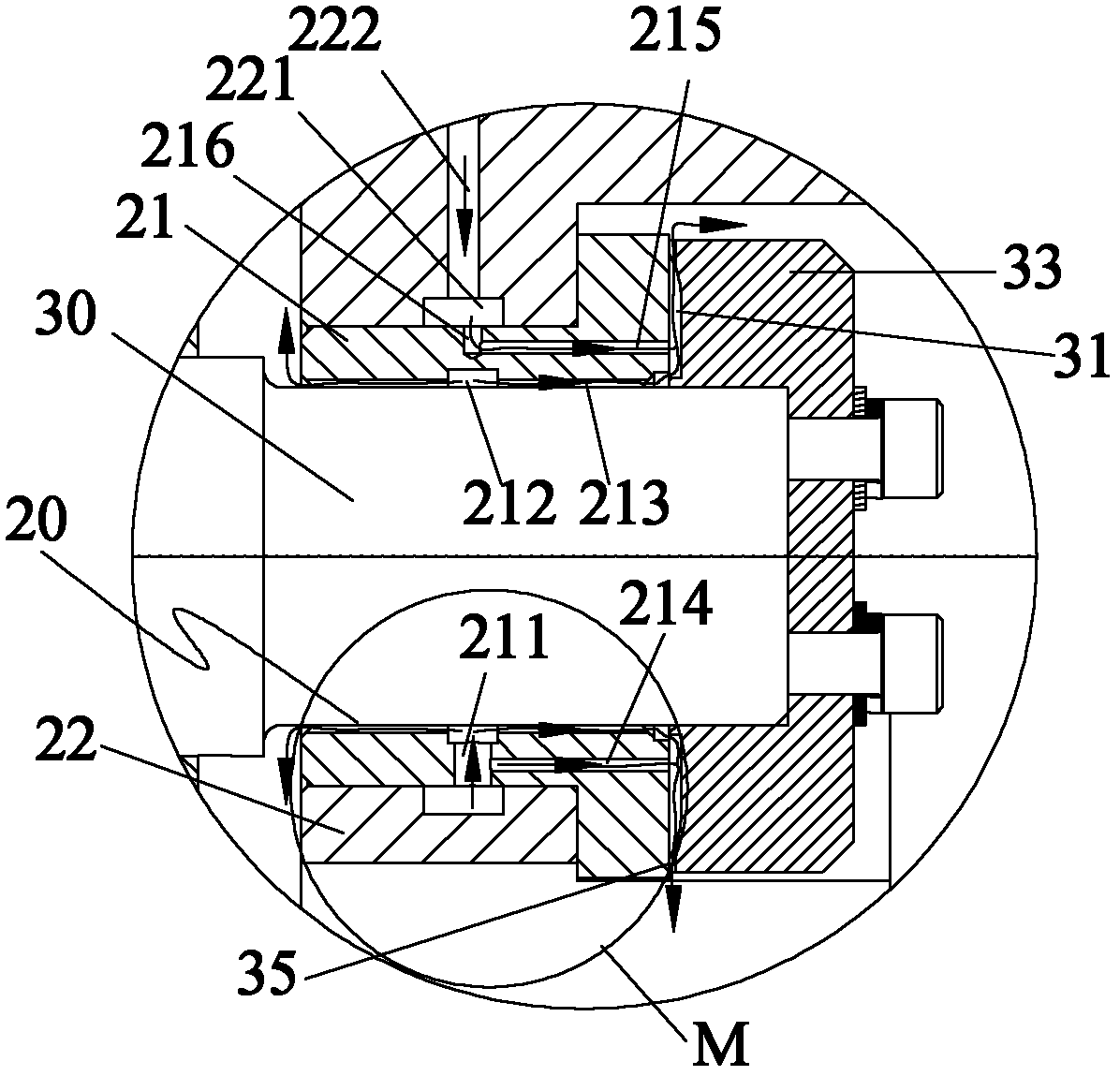

[0032] Such as image 3 , Figure 4 , Figure 7 and Figure 8 As shown, according to the embodiment of the present invention, the rear bearing 20 includes a rear bearing pad 21 and a rear bearing pad positioning member 22 . The rear bearing bush locator 22 is fixedly arranged, and forms a positioning and supporting effect on the rear bearing bush 21 . The rear bearing bush 21 is sheathed on the rotor 30 , and a thrust plate 33 is fixedly arranged outside the first end of the rear bearing bush 21 . The thrust disc 33 is fixedly connected to the rotor 30 by bolts, and forms an axial force on the rear bearing bush 21 .

[0033] The rear bearing bush positioning member 22 includes a rear bearing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com