Method and device for measuring direct current magnetic bias error characteristics of current transformer

A technology of current transformers and error characteristics, applied in the field of high-voltage electrical measurement and inspection, to achieve traceability solutions, easy adjustment, and independent measurement systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

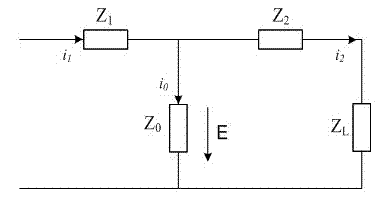

[0040] Embodiment 1, current comparison type error characteristic measurement and verification method and device:

[0041] Select standard power frequency AC current source, standard DC current source, standard current transformer CT according to the setting requirements N , as well as conventional transformer tester HEC-H, see attached Figure 4 , the standard current transformer CT N The output signal serves as a standard signal, CT N with the current transformer under test CT X The secondary output is connected into a differential circuit, and the standard current transformer CT N Only connected to the power frequency current source, the measured current transformer CT X At the same time through the power frequency current source and DC power supply, CT X with CT N The homonym end-butt, CT N with CT X The current difference between enters the transformer calibrator HEC difference measuring terminal K, CT N The other end is connected to the T of the transformer cali...

Embodiment 2

[0045] Embodiment 2, method and device for measuring and verifying voltage comparison error characteristics:

[0046] Select standard power frequency AC current source, standard DC current source, standard current transformer CT according to the setting requirements N , shunt R N1 , shunt R N1 and R o , Conventional dual-channel data acquisition card (the 5922 acquisition card of NI Company is used in this embodiment), and the analog quantity measurement part of the electronic transformer calibrator. See attached Figure 5 , the standard signal in the industrial frequency power supply passes through the standard current transformer CT N and subsequent connection of the shunt R N1 Convert standard current signal to standard voltage signal U a , the standard DC signal passes through the shunt R D Obtained, the power frequency signal and the DC signal are converted in the same proportion, and the standard current transformer together with the shunt R connected behind N2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com