Tube blank bilateral reverse central spindle thrusting reducing die and process

A technology of mandrel and tube billet, which is applied in the technology of double-sided reverse mandrel pushing and reducing the diameter of the tube billet and in the field of molds, which can solve the problems of large diameter reduction force, large increment of tube billet wall thickness, and tube billet instability. Achieve the effects of small diameter reduction force increase and small wall thickness increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

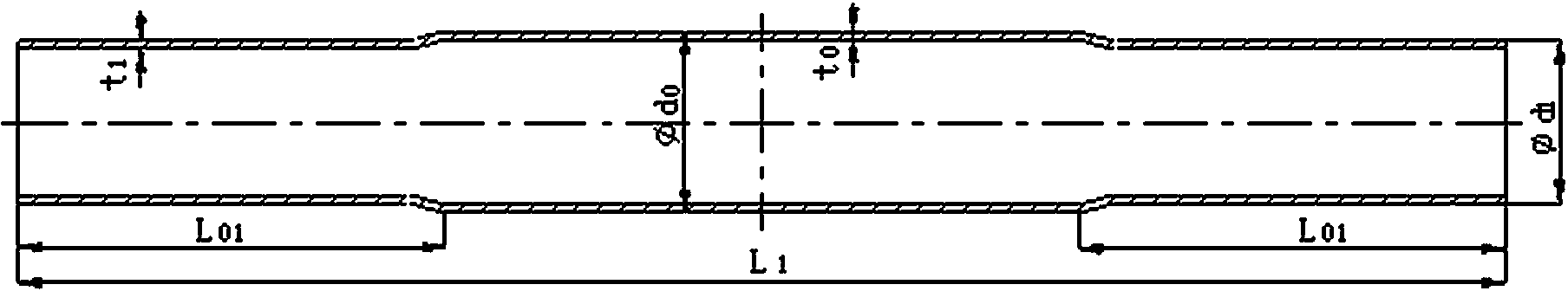

[0031] figure 1 It is a schematic diagram of the reduced-diameter tube blank of the embodiment of the present invention, and the selected seamless steel round tube has an outer diameter of d 0 =180mm, wall thickness t 0 = 8mm, the length is 1395mm. After both sides of the tube blank are reduced in diameter, the outer diameter d 1 =162mm, wall thickness t 1 = 8.3mm, length L 1 =1435mm, and the length of the diameter-reducing areas on both sides is 420mm respectively.

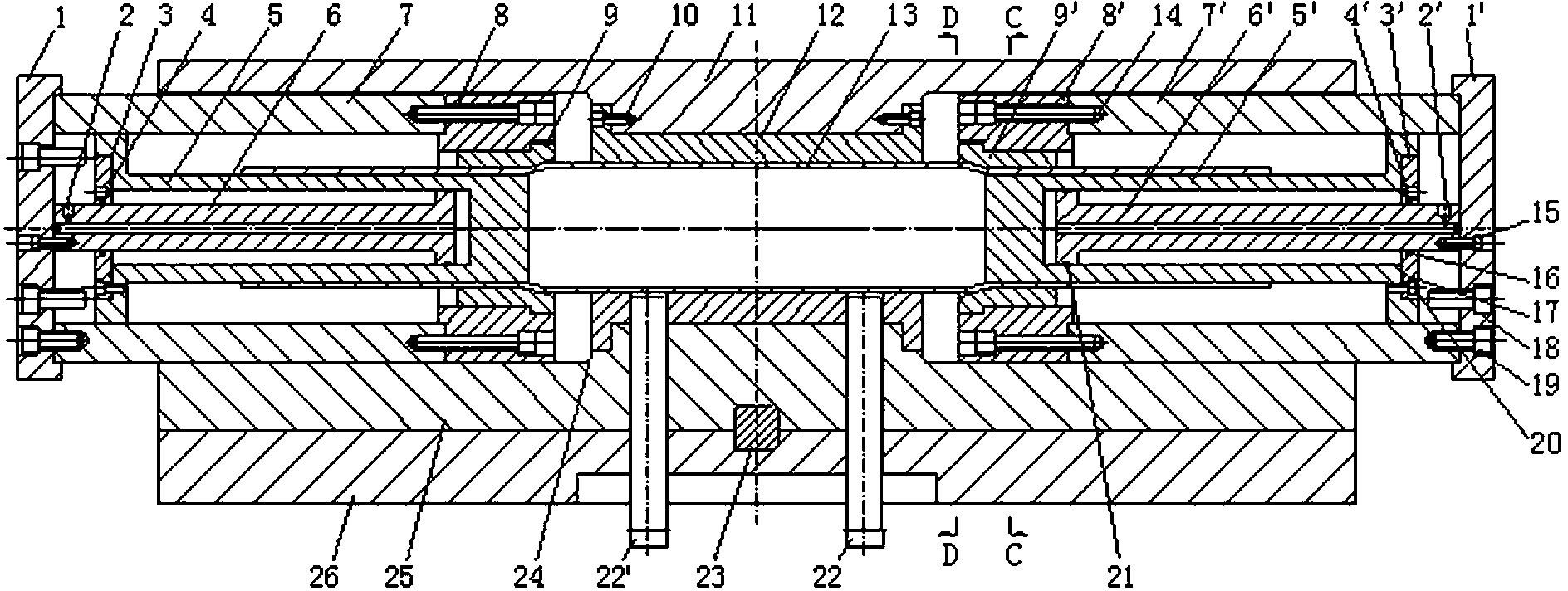

[0032] The process of pushing and reducing the diameter of the tube blank on both sides of the reverse mandrel in the embodiment of the present invention includes the following steps:

[0033] 1) Clamping tube blank:

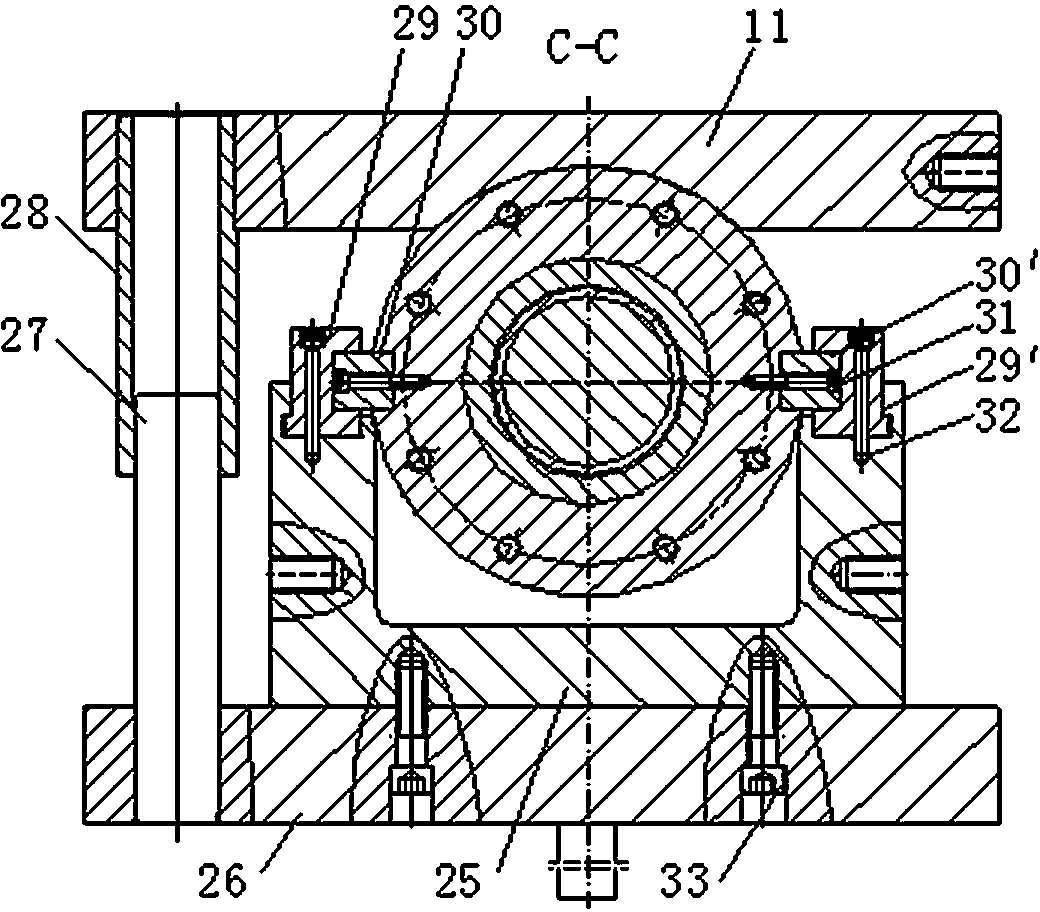

[0034] Put the tube blank 13 coated with saponification liquid on both sides on the lower fixed die 25 of the reducing die, the left and right sliders of the three-way hydraulic press drive the left and right reducing die components to feed axially, and the upper slider of the hydraulic press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com