A method for selecting and matching ladles in a steelmaking plant

A technology for steelmaking plants and ladles, applied in the manufacture of converters, casting molten material containers, manufacturing tools, etc., can solve the lack of overall regulation and predictability of ladle selection technology, and can not effectively realize energy saving and consumption reduction in the ladle turnover process Control and other issues, to achieve the effect of shortening the waiting time for empty packages, speeding up the rhythm of turnover and shortening the baking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

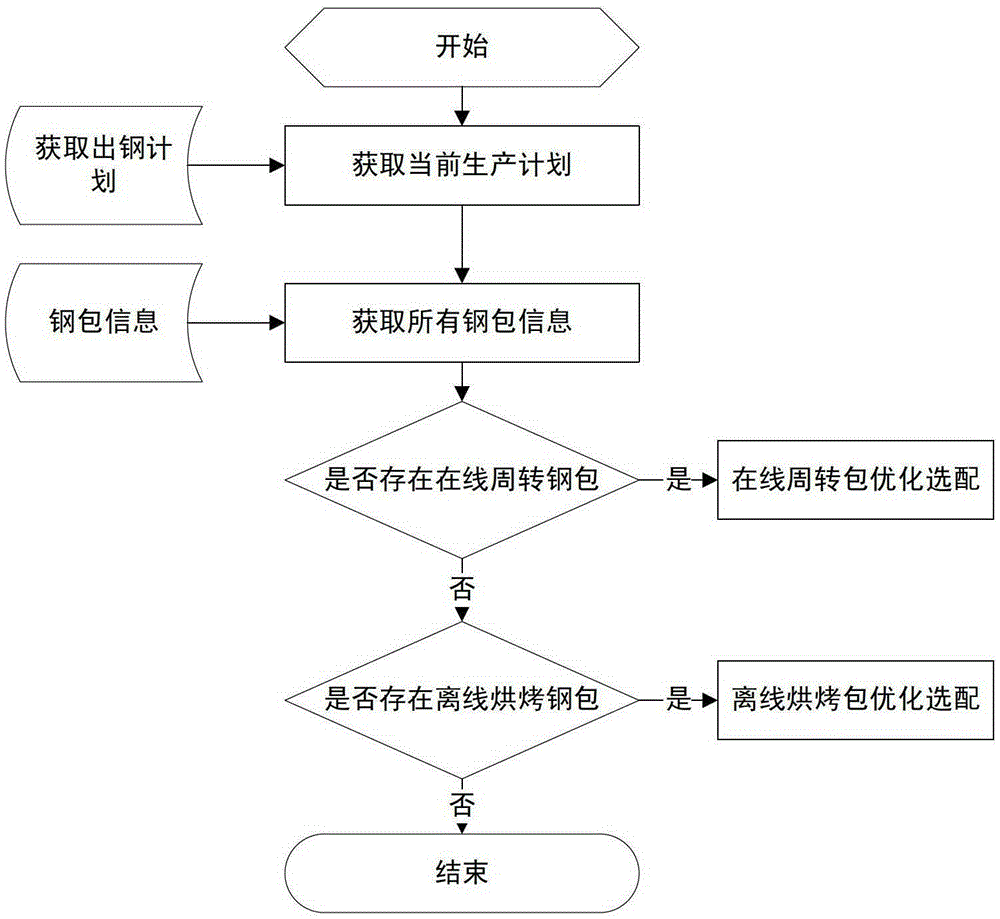

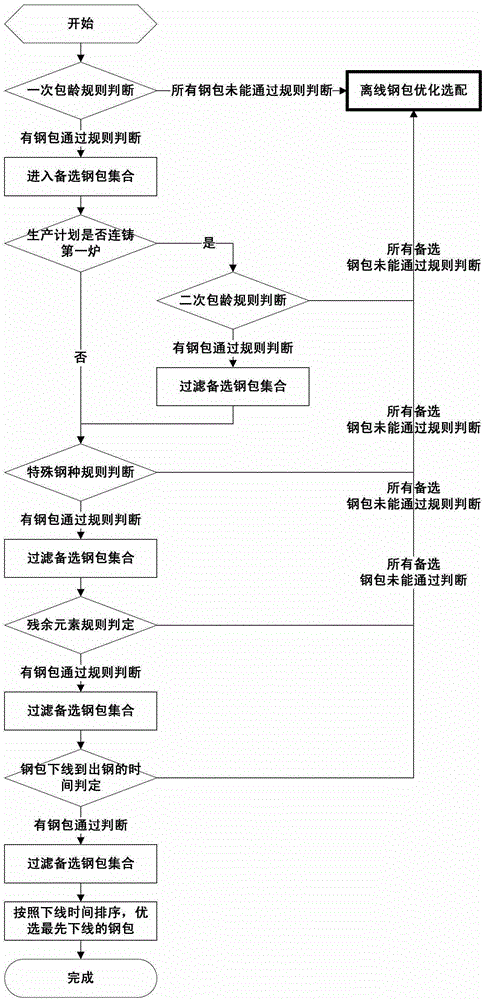

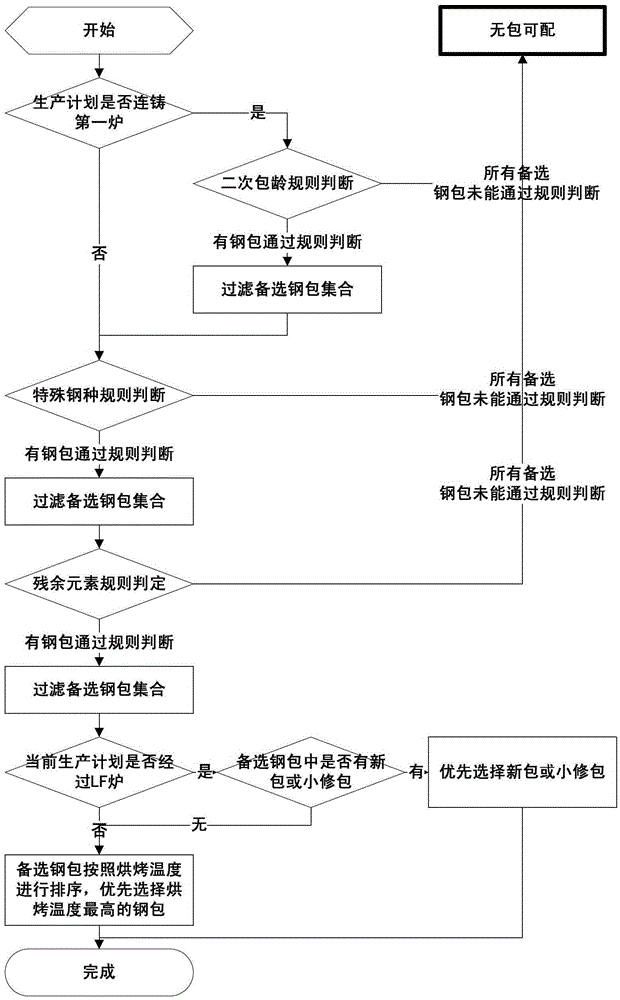

Method used

Image

Examples

Embodiment Construction

[0032] The method for selecting and matching ladles in steel mills provided by the present invention requires the following devices: at least three computers, one computer for recording ladle information and running the ladle matching system software, the ladle matching system software includes this The invention provides a method for selecting and matching ladles in steel mills; a storage computer for collecting and storing data; another MES computer running the enterprise's three-level MES system, and the three computers together form a small local area network.

[0033] The storage computer obtains the ladle information and the production plan information provided by the three-level MES system at regular intervals according to the data acquisition program, and stores the obtained information in the storage computer, and the ladle information is entered manually after the ladle information is updated. to the running computer, and then collected from the running computer by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com