Decorative pattern hot plate for two-layer bag making machine

A bag making machine and pattern technology, which is applied in container manufacturing machinery, paper/cardboard containers, box making operations, etc. It can solve the problems of easy holes, low sealing strength, and short sealing time, and the heat dissipation area is not easy to elongate , Reduce the sealing area and accelerate the effect of sealing cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

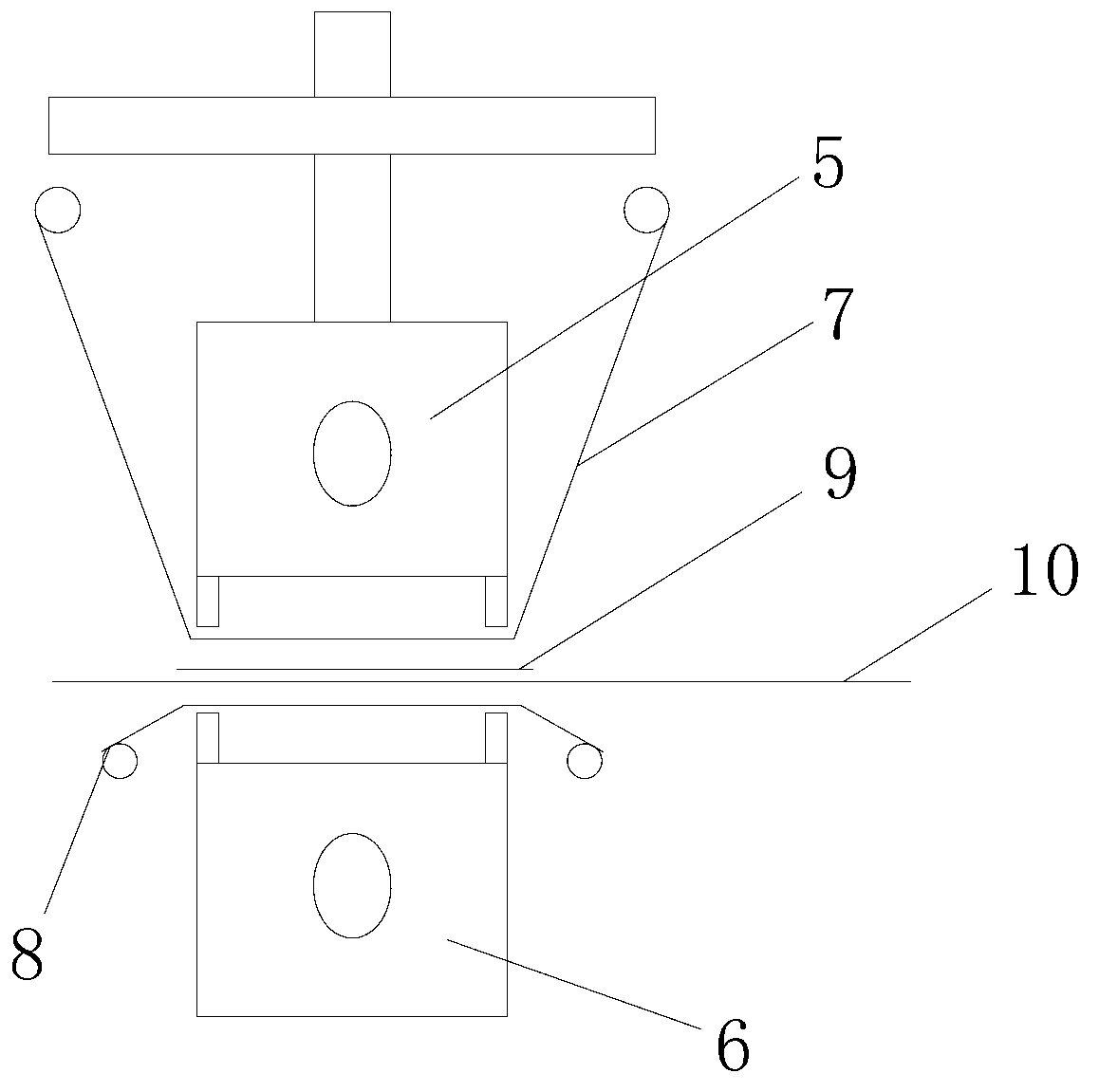

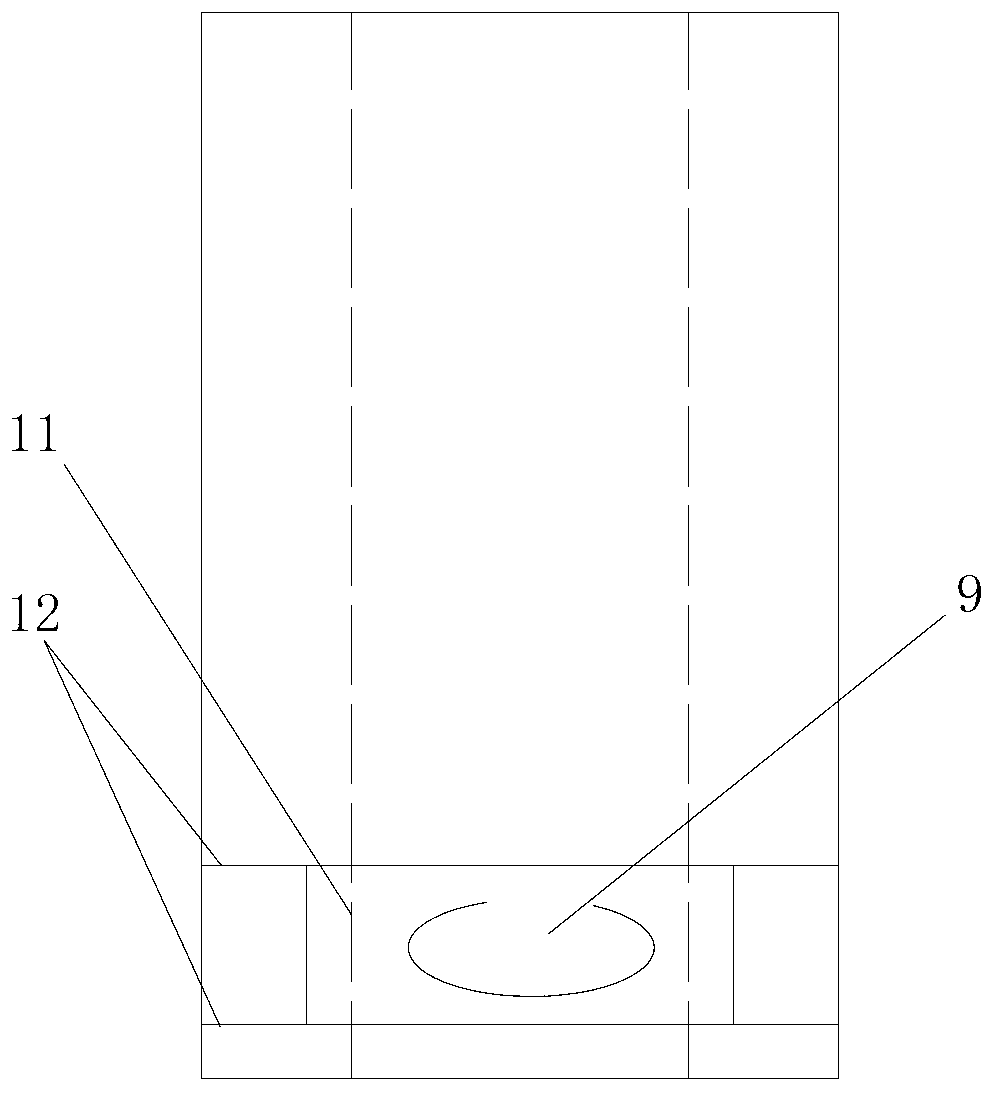

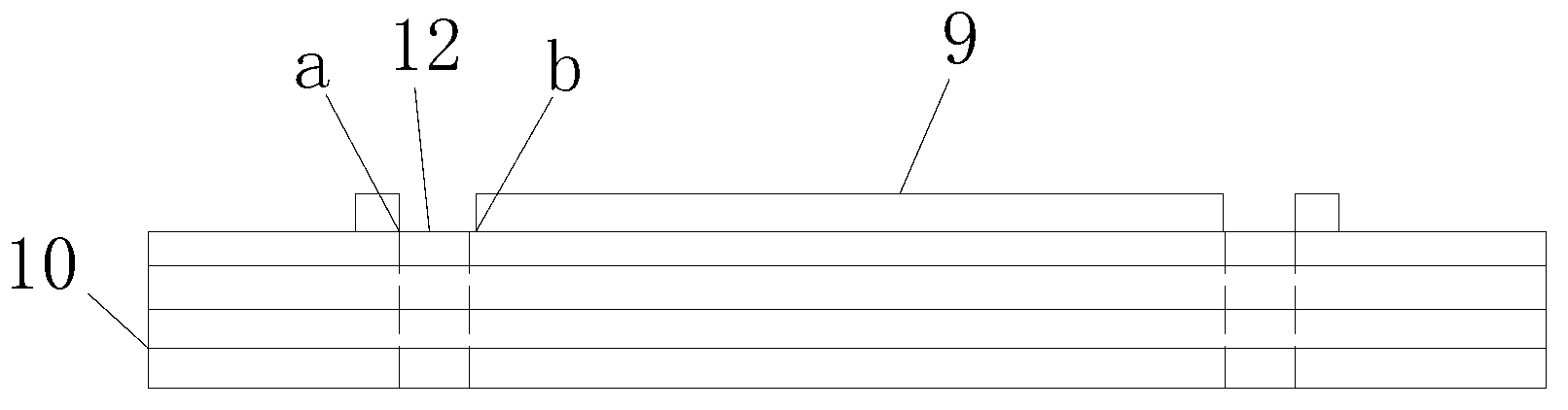

[0018] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0019] as attached Figure 4 to attach Image 6 As shown, the present invention includes: a heat plate body 1 and a contact plate 2, two contact plates 2 are provided, the heat plate body 1 and the contact plate 2 are fixedly connected as one, and the contact surface at the bottom of the contact plate 2 is cut with a plurality of square Pattern 3, the square pattern 3 is staggered along the length direction of the contact plate 2, and the center of the square pattern 3 is provided with a round hole 4. The square pattern 3 is a square pattern, and the length and width of the square pattern 3 are equal to the width of the contact plate 2. Similarly, the distance between the square patterns 3 is 3 / 4 of the width of the contact plate 2, and the depth of the circular hole 4 in the center of the square pattern 3 is 3 / 4 of the width of the contact plate 2.

[0020] a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com