Novel dual-mass flywheel torsion damper

A dual-mass flywheel and torsional shock absorber technology, applied in flywheels, counterweights, etc., can solve problems such as the difficulty in meeting the lightweight requirements of automobiles, the difficulty in wiring electronically controlled variable inertia systems, and the large amount of magnetorheological fluid used to achieve easy Layout and implementation, reduced sealing technology requirements and processing, high controllability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

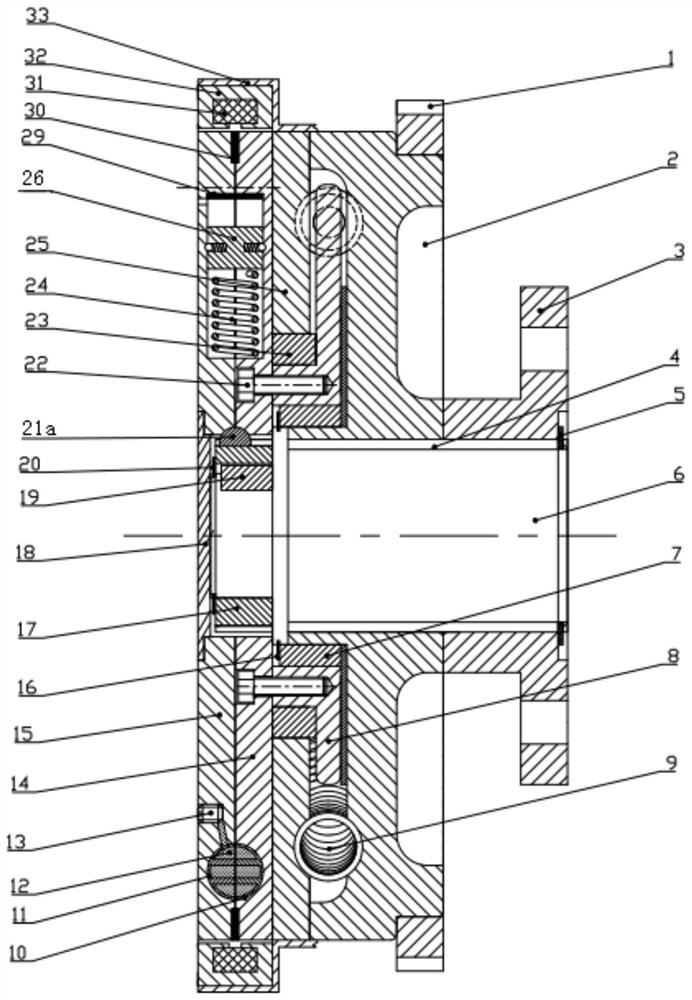

[0090] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

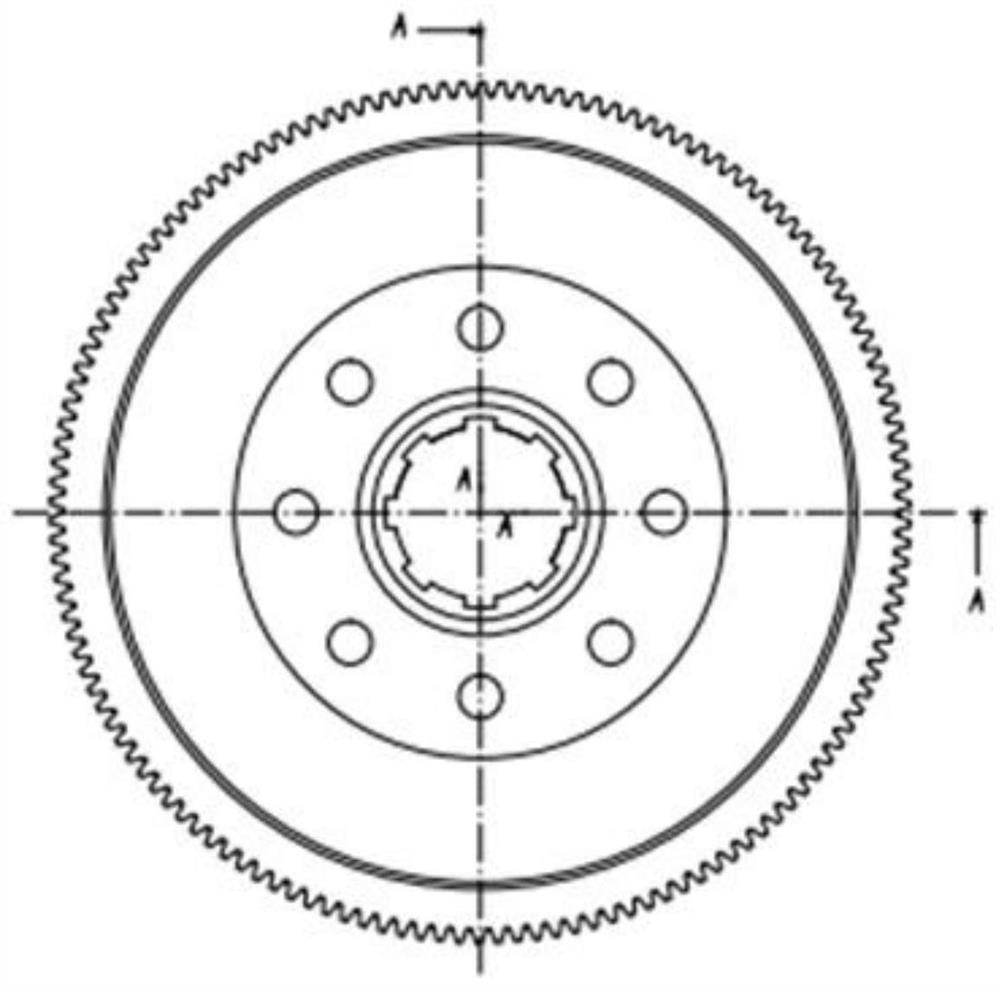

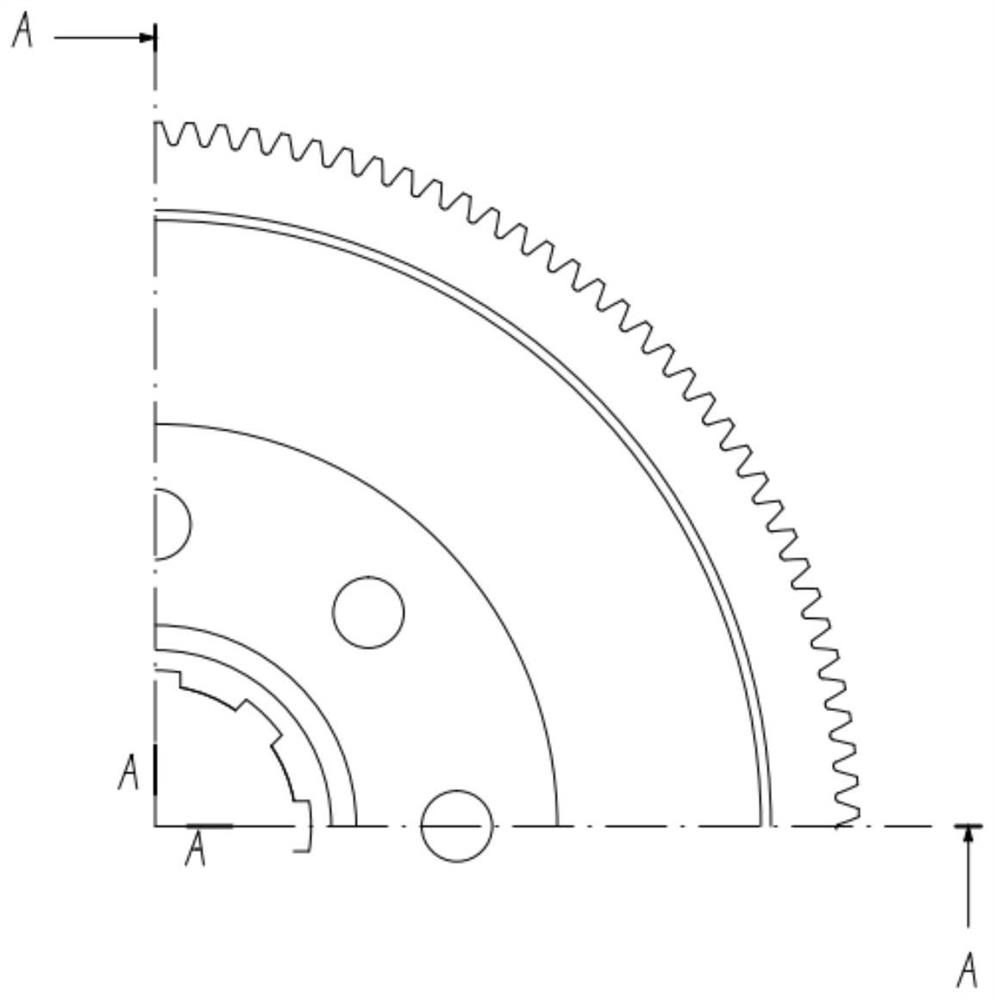

[0091] Such as Figure 1-19 As shown, the present invention provides a novel dual-mass flywheel torsional damper, which mainly includes: starting ring gear 1; driving flywheel 2; driving flywheel arc groove 2a; connecting flange 3; spline 4; Spring 5; transmission shaft 6; sliding bearing 7; force transmission plate 8; variable pitch arc spring 9; first half liquid flow channel body 10; second half liquid flow channel body 11; magnetorheological fluid 12; oil plug 13 ; Inner driven flywheel 14; Outer driven flywheel 15; Shoulder spring 16; Transmission gear 17; Connecting bolt 22; sliding bearing 23; straight spring 24; sealing plate 25; sealing plate arc groove 25a; additional mass block 26; steel ball spring 27; steel ball 28; Yoke 32; fixed bracket 33; first piston 34a; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com