Damping component of automobile suspension assembly

A kind of assembly and automobile technology, applied in the direction of shock absorber, liquid shock absorber, shock absorber, etc., can solve the problem that the shock absorber cannot adapt to the impact of the road surface and affects the riding comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following examples are used to specifically describe the present invention, which are only used to further illustrate the present invention, and should not be understood as limiting the protection scope of the present invention.

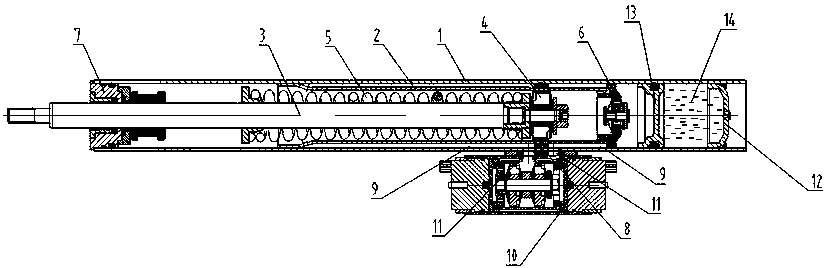

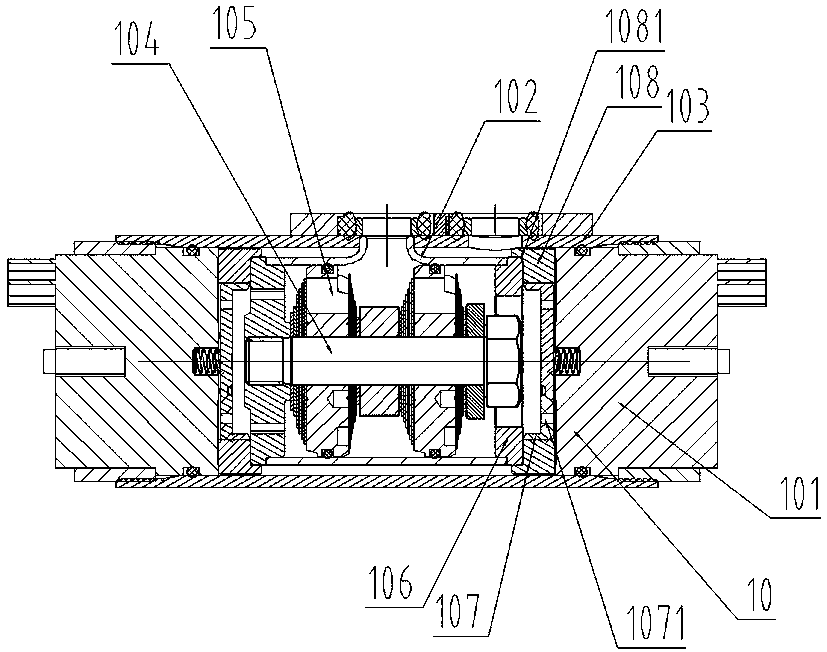

[0012] As shown in the figure, the present invention discloses a damping and vibration reduction component of an automobile suspension assembly, including an oil cylinder 1, a working cylinder 2, a piston rod 3, a piston 4 and a buffer spring 5. The working cylinder 2 is arranged in the inner hole of the oil cylinder 1. Among them, one end of the working cylinder 2 is hermetically connected with the inner wall of the oil cylinder 1, and the other end of the working cylinder 2 is hermetically connected with the inner wall of the oil cylinder 1 through an extension valve 6. The piston 4 is arranged in the working cylinder 2, and the piston 4 is installed on the piston rod. At one end of 3, the buffer spring 5 is installed on the piston rod 3. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com