Nanometer complex phase photochromic material and preparation method

A nanocomposite, photochromic technology, applied in the field of polyurethane nanocomposite phase photochromic materials and preparation, can solve the problems of difficult to achieve full color change of red, orange, yellow, green, blue and purple, single changing color, poor color changing effect, etc. The effect of rich variation, high response sensitivity, and increased number of electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Nanocomposite photosensitive color-changing mixed solution and film

[0037] (1) Preparation of pre-polymerization solution: 100 grams of polyethylene glycol (PEC) and 50 grams of dimethylolpropionic acid (DMPA) were added to 100 ml of butanone solution, and at room temperature, 150 grams of isocyanate monomer (TDI ) and 0.2 grams of dibutyltin dilaurate (T-12), heated to 65 ° C, stirred for 30 minutes, after 100 minutes of reaction, added 82 grams of β-hydroxypropyl acrylate (HPA) and 0.2 grams of T-12, after 120 minutes of reaction , lower the temperature to 50°C, add the reaction solution into 1000ml of aqueous solution containing 40g of triethylamine, stir for 90min, then add core-shell structure nanomaterials, respectively 3g of ZnO, 1g of ZnS, 3g of WO 3 , to obtain the prepolymerization solution.

[0038] (2) Prepare the mixed solution of the photosensitive color-changing system: add 1 gram of auxiliary color-changing material Fe with core-shell struct...

Embodiment 2

[0041] Example 2 Nanocomposite photosensitive color-changing mixed solution and film

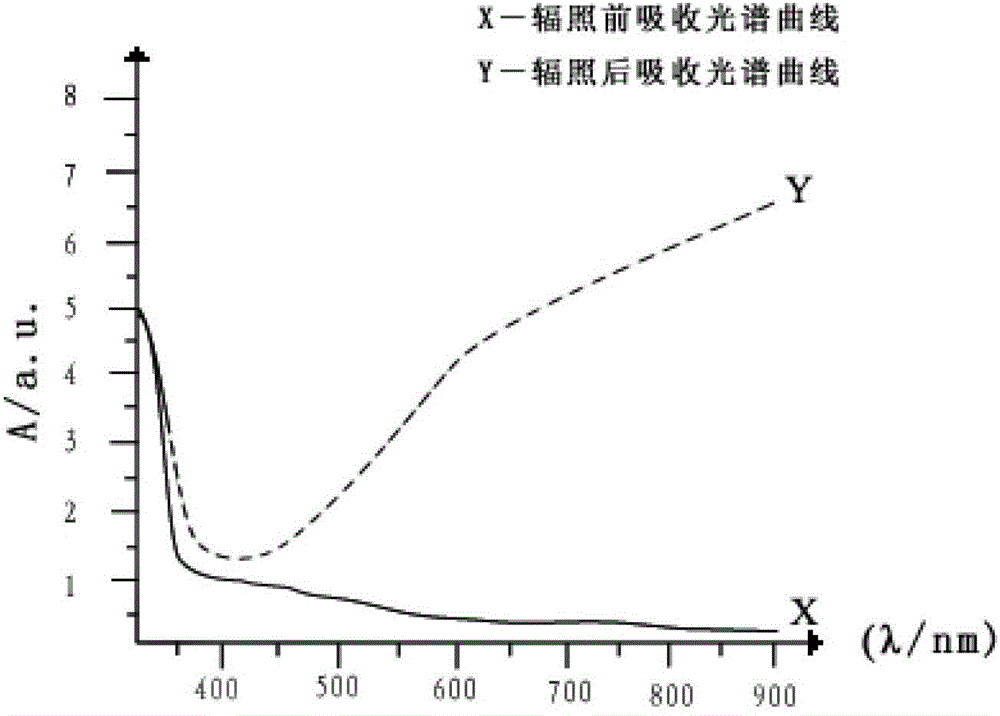

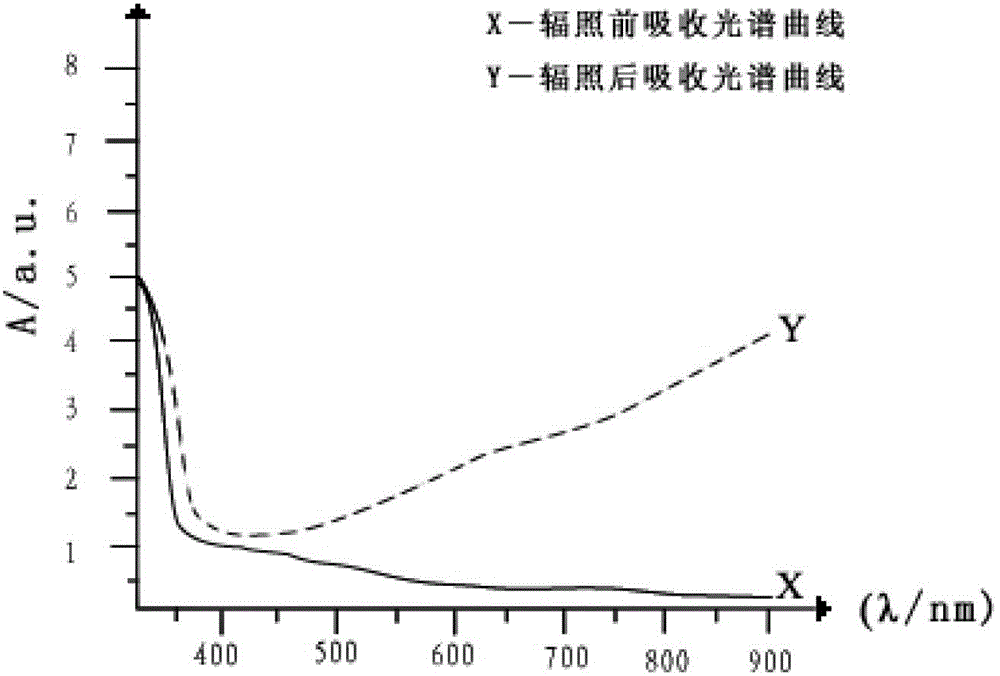

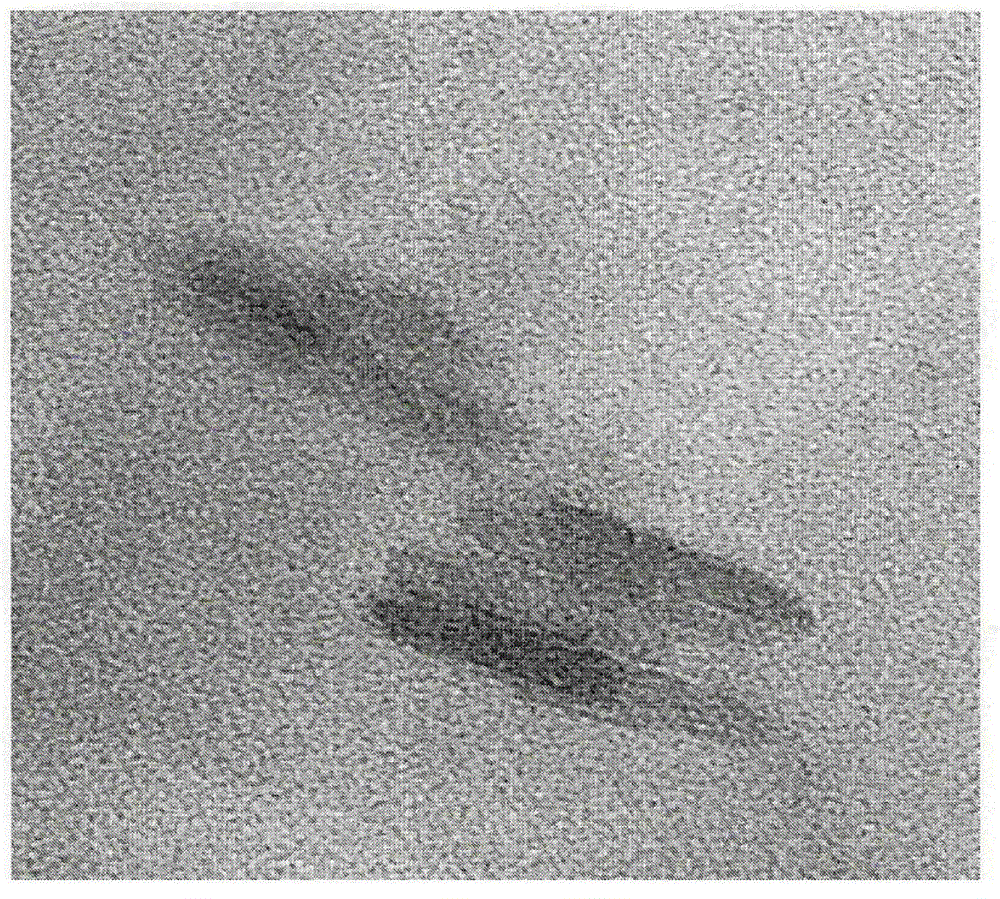

[0042] According to the same method described in Example 1, the nanocomposite photochromic mixed solution is prepared, the difference is that ZnO, ZnS, WO 3 The addition amount is 6 grams, 2.5 grams, 4 grams respectively, and the auxiliary color-changing material is 2.5 grams of cobalt oxide (purple) nanomaterials, and then the mixed solution is prepared a film according to the same method as in Example 1. figure 1 It is the absorption spectrum graph of the nanocomposite photosensitive color-changing mixed solution prepared in Example 2. image 3 It is the transmission electron microscope scanning picture of photosensitive color-changing film.

Embodiment 3

[0043] Example 3 Nanocomposite photosensitive color-changing mixed solution and film

[0044] According to the same method described in Example 1, the nanocomposite photochromic mixed solution is prepared, the difference is that ZnO, ZnS, WO 3 The addition amount is 6 grams, 3.5 grams, 7 grams respectively, and the auxiliary discoloration material is 2 grams of cobalt oxide (purple), 1 gram of iron oxide (tan), then this mixed solution is prepared film according to the same method of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com