Auxiliary jet air supply system with exhaust valve

An auxiliary nozzle and air supply system technology, applied in textile, textile, papermaking, looms, etc., can solve the problem of not meeting the control requirements of auxiliary nozzles, and achieve the goal of improving high-speed adaptability, reducing air resistance, and enhancing airflow control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

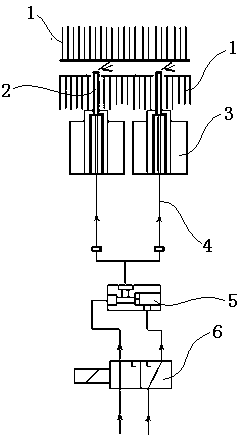

[0026] see figure 1 As shown, an auxiliary nozzle air supply system with an exhaust valve includes several auxiliary nozzles 2 arranged on a special-shaped reed 1, the rear end of the auxiliary nozzle 2 is arranged on an auxiliary nozzle seat 3, and the auxiliary nozzle 2 Connect with an exhaust valve 5 through the air pipe 4, and the exhaust valve 5 is connected with a two-position three-way electromagnetic valve 6, and the two-position three-way electromagnetic valve 6 is controlled by an electromagnetic valve time control system .

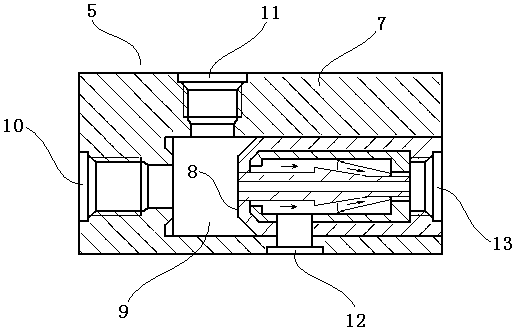

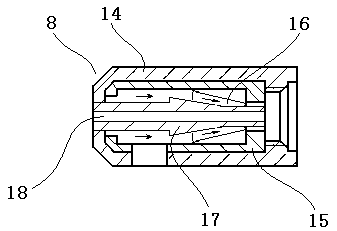

[0027] Further, see figure 2 As shown, the exhaust valve 5 is composed of a valve body 7 and an exhauster 8, and the valve body 7 is provided with an auxiliary jet air inlet hole 10, an auxiliary jet air outlet hole 11, and an exhaust air inlet hole 12. and an open cavity 9; the auxiliary jet air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com