Method for regulating vacuum degree of stock discharge box

An adjustment method and headbox technology, applied in textiles and papermaking, paper machine, paper machine wet end, etc., can solve the problem that the vacuum degree of the headbox is difficult to adjust accurately, and the adjustment method is simple, easy and reliable High performance and high precision, intuitive adjustment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

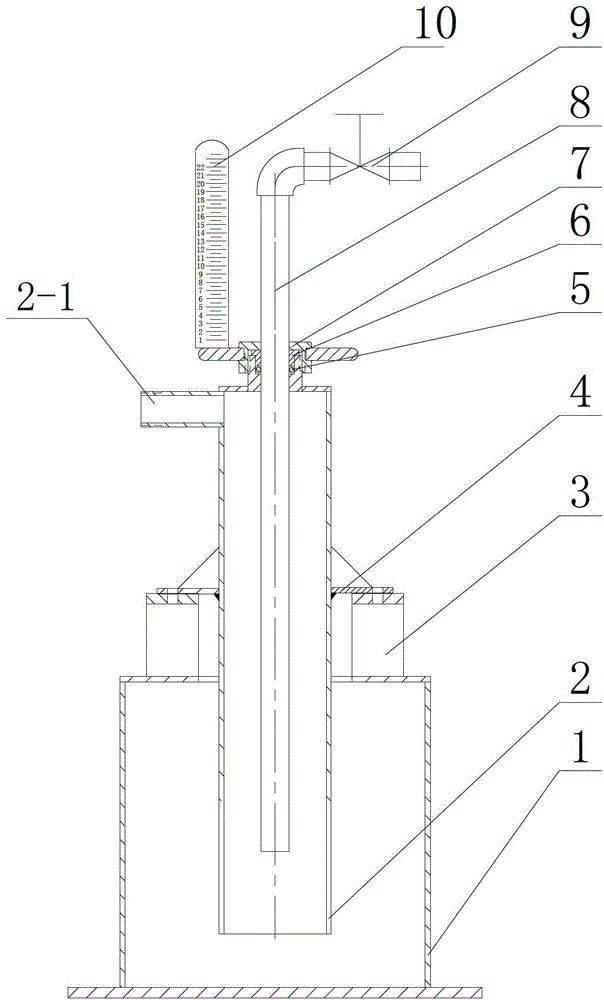

[0024] Such as figure 1 As shown, the headbox vacuum adjustment device of the present invention includes a water storage barrel 1, a pressure regulating cylinder 2, and a pressure regulating tube 8; the lower end of the pressure regulating cylinder 2 extends into the water storage barrel 1 through a support assembly; the pressure regulating The lower end of the pipe 8 extends into the pressure regulating cylinder 2 from the upper end of the pressure regulating cylinder 2, and a movable sealing assembly is provided at the connection between the pressure regulating pipe 8 and the pressure regulating cylinder 2; the side wall of the upper end of the pressure regulating cylinder 2 is provided There is an outlet pipe 2-1.

[0025] The movable sealing assembly includes a sealing ring 5, a sealing sleeve 6, and a sealing cover 7; the sealing cover 7 is unscrewed, and the pressure regulating tube 8 can be adjusted up and down in the pressure regulating cylinder 2, and the sealing ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com