Screening device for railway ballasts

A screening device and ballast technology, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of low screening efficiency and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

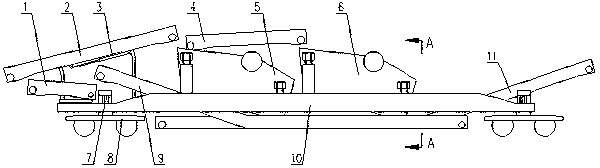

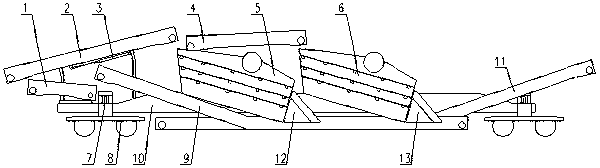

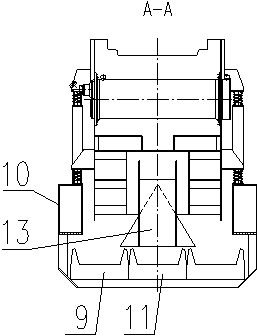

[0022] figure 1 , figure 2 Among them, the present invention includes a frame 10 with a side beam with a low middle convex structure at both ends, and the left and right ends of the frame 10 fall on two bogies 8, and the frame 10 and the bogies 8 are provided with a leveling cylinder 7.

[0023] The ballast conveying device A2 and the ballast conveying device B4 are located at the top, the first vibrating screen 5 and the second vibrating screen 6 and the first ballast hopper 12 arranged at the outlet of the first vibrating screen 5 and the second vibrating screen 6 are discharged The second ballast bucket 13 arranged at the mouth is located in the middle, the clean ballast conveying device 9 and the waste ballast conveying device 11 are located at the bottom, the swing conveying device 1 is at the left end of the frame 10, and below the mixed ballast conveying device A2. Above-mentioned parts all take root and are fixed on the frame 10. The discharge port of the ballast co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com