Overlapping device of upper geotechnical cloth of composite geo-membrane

A technology of composite geomembrane and lapping device, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of narrow suture belt, material waste, unbearable, etc., to reduce tensile stress, make full use of materials, and withstand Effect of Seam Area Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

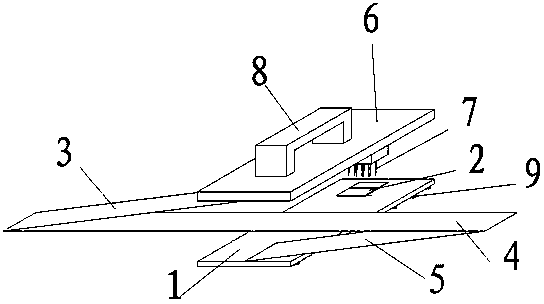

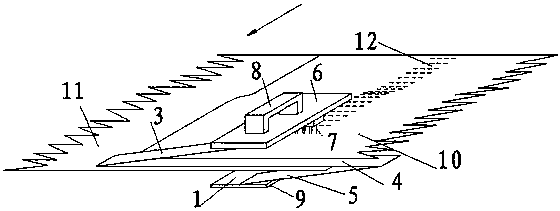

[0014] Such as figure 1 As shown, the present invention includes a base plate 1 and a top plate 6. The top plate 6 is located above the base plate 1. One end of the upper steel strip 3 is connected to the top plate 6, and the other end is connected to one end of the middle steel strip 4. The other end of the middle steel strip 4 is connected to the bottom. One end of the steel belt 5 is connected, and the other end of the lower steel belt 5 is connected to the bottom plate 1 . The upper steel strip 3, the middle steel strip 4 and the lower steel strip 5 form a Z-shape, and the joints make the Z-shaped steel strips elastic. . A needle-exiting device 7 is installed on the bottom of the top plate 6 , and a needle-bearing plate 2 adapted to the position of the needle-exiting device 7 is provided on the bottom plate 1 . The needle-exiting device 7 can adopt a structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com