High performance plastic steel thin wood composite door and window

A high-performance, thin wood technology, applied to the direction of the wing frame, etc., can solve the problems of shortened service life, damage to the overall aesthetics, easy aging, etc., and achieve the effect of improving air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A preferred embodiment of a high-performance plastic-steel thin-wood composite door and window of the present invention will be described in detail below in conjunction with the accompanying drawings:

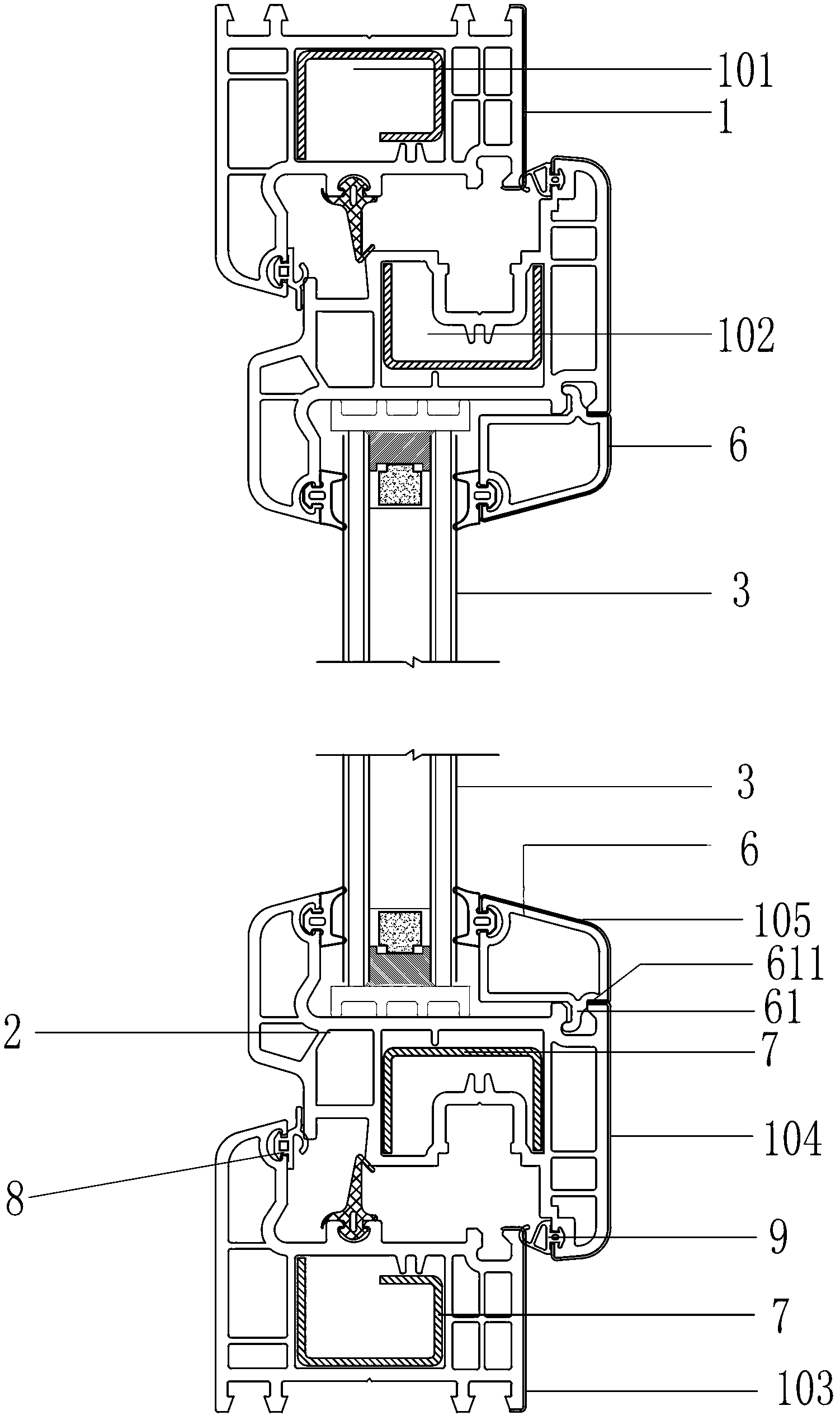

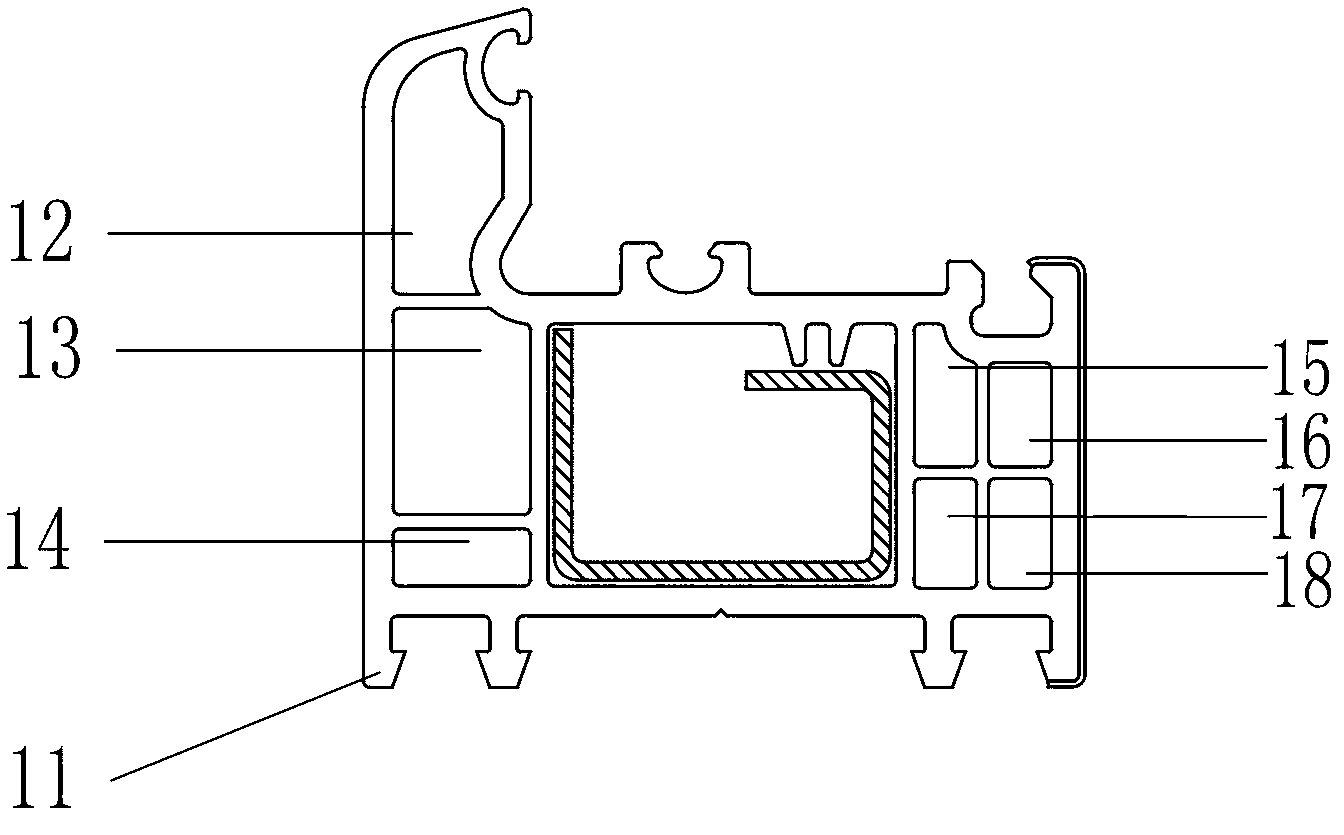

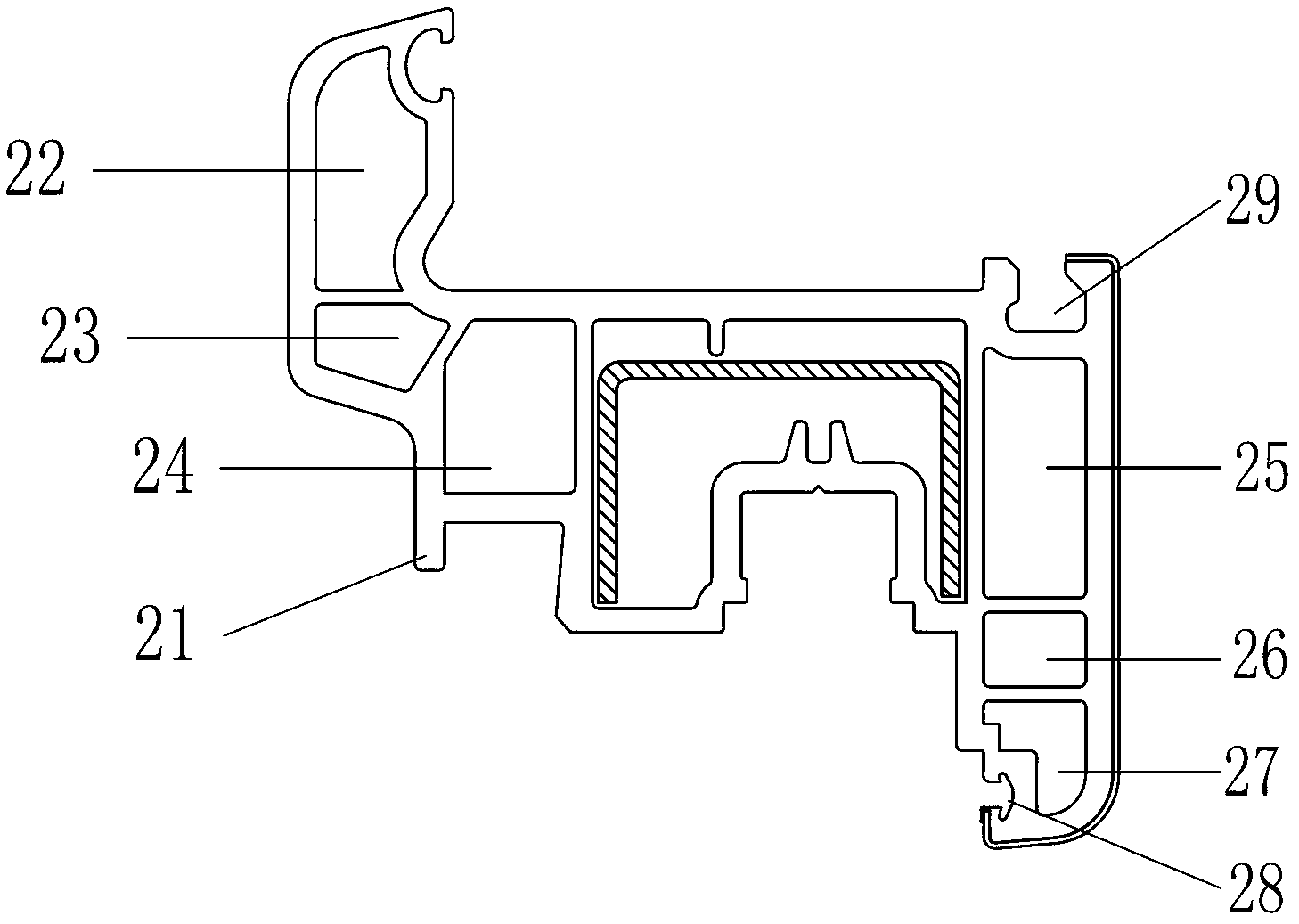

[0021] Such as figure 1 , figure 2 , image 3 A high-performance plastic-steel thin-wood composite door and window shown includes a frame material 1, a fan material 2, a frame material edge 4, a fan material edge 5, a pressing line 6, and a glass 3, and the frame material 1 and the fan material 2 are respectively made of PVC profiles; The frame material 1 has a first transverse arm and a vertical arm. The positive section of the frame material 1 is in an "L" shape from the indoor side to the outdoor side. One side of the wall is provided with a first convex strip 11, the outer surface of the vertical arm is composed of connected vertical surfaces and inclined surfaces, and the inner surface of the vertical arm is provided with a frame fan outer rubber strip 8 to coope...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap