L-shaped outer spherical surface aligning bearing seat with safety protection cover

A safety protection, self-aligning bearing technology, applied in the direction of shaft and bearing, bearing components, bearing assembly, etc., can solve the problems of inconvenient inspection and maintenance, and achieve the effect of easy observation and maintenance, alleviation of inconvenience, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

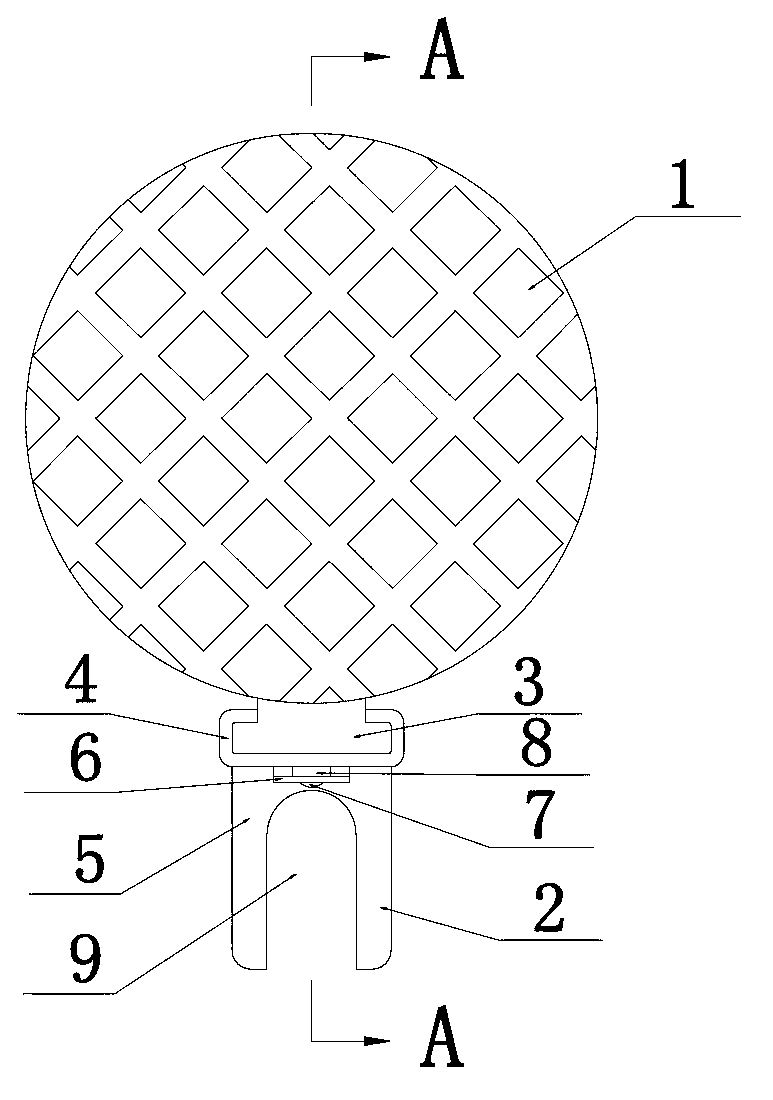

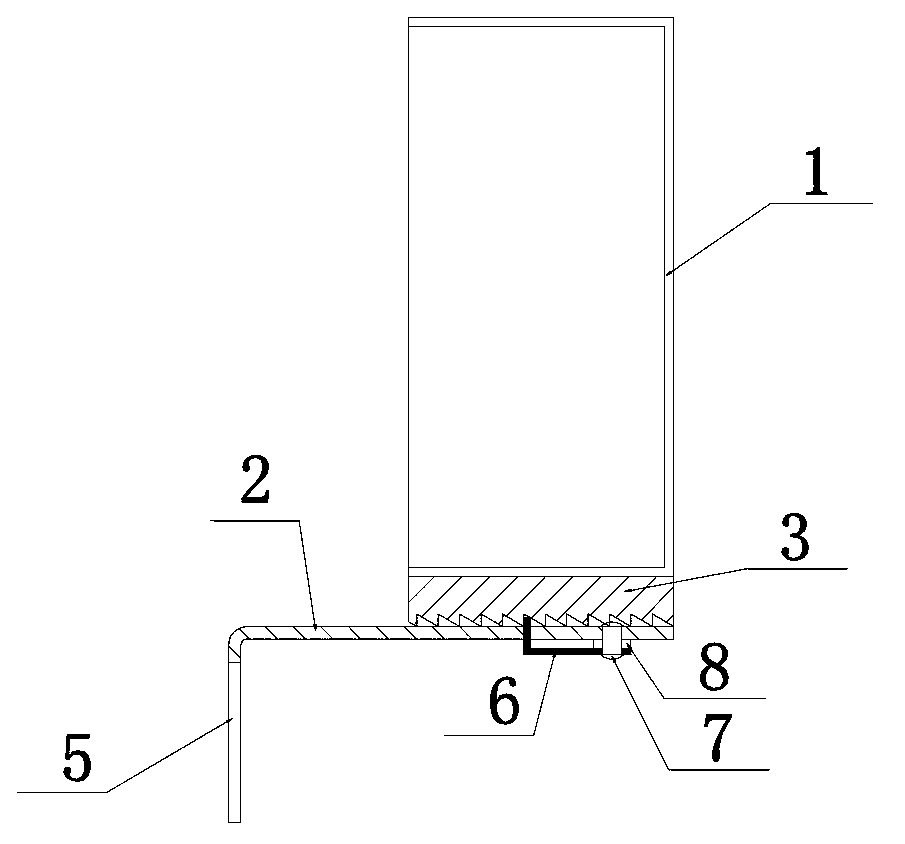

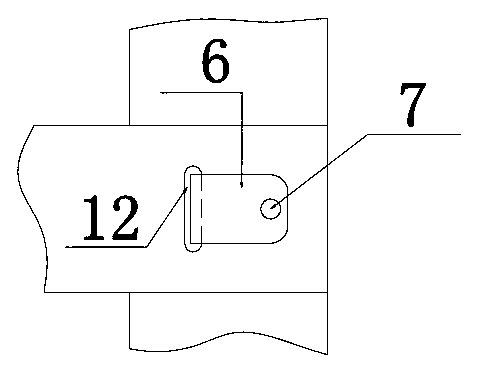

[0022] like figure 1 As well as figure 2 A safe protective cover of the L or F lying spherical strotonal bearing seat, which is shown in the Safety protective cover, includes a cup -shaped mesh cover and a fixed bracket 2.like Figure 4 It shows, a cup -shaped mesh 1 outer wall is welded with a saw -shaped spine tooth 3, the saw -shaped spinal teeth 3 diagonal angle along the cup of the cup -shaped mesh cover 1, the back of the saw -shaped spinal teeth 3 has a symmetrical step, a saw shape, a saw -shaped shape.Two straight grooves 11 with the outer wall welding of the outer wall of the cup -shaped mesh to form two straight grooves 11.like Figure 5 The fixed bracket 2 is composed of the fixed department 5 and the connection part 4 set up in a right angle.The arms of the C -shaped slot 10 of the C -shaped slot 10 are buckled within the direct slot 11, respectively.like figure 2 As well as image 3 It is shown that the bottom 4 is set with spring steel sheet 6, and one end of the sprin...

Embodiment 2

[0024] like Figure 6 As well as Figure 7 A L -type outer spherical corpus bearing seat, which is shown in the L -type outer spherical rhyme, includes the body 13 and the safety protective cover.The fixed threaded holes 14, the safety protective cover uses the full protective cover shown in Example 1, and the long slot 9 of the fixing department 5 is set in the fixed thread 14 of the lower fixing threads through the bearing seat fixing screw 16.When used, the cup -shaped mesh cover 1 inserted into the C -shaped slot 10 of the fixed bracket 2 through two straight grooves 11 of the saw -shaped spiny teeth 3, and the spiny paw formed by the spring steel sheet 6 passed the saw -shaped spinal teeth 3 phase phase.The mesh automatically locks the cup -shaped mesh cover 1, so that it cannot fall off.Use a word screwdriver to insert the spring steel sheet 6 and the 3mm gap between the fixed bracket 2 to lift the spiny paws, which can be easily pulled out of the cup -shaped mesh cover 1 alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com