Welding method of metal pipe fitting

A technology of metal pipe fittings and welding methods, which is applied in the direction of non-detachable pipe connections, pipes/pipe joints/pipe fittings, passing elements, etc., can solve the problems of increasing the wall thickness of the lining pipe, reducing the inner diameter of the welded pipe fittings, and misalignment, etc. Achieve the effect of uniform welding seam, improve straightness and prevent the phenomenon of hanging tumor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

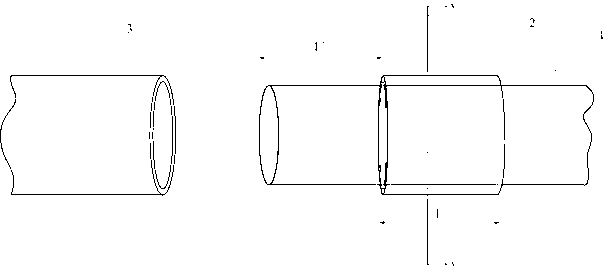

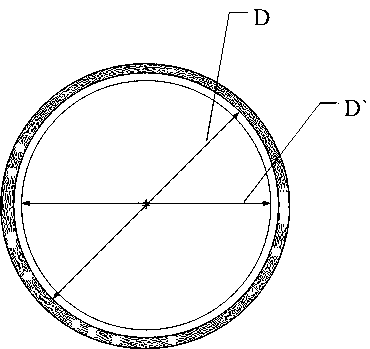

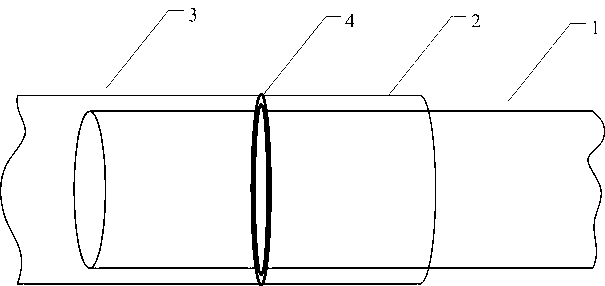

[0029] Figure 1-Figure 4 It is a schematic diagram of the first structure of the welding method for metal pipe fittings in the present invention, showing the first specific implementation mode of the present invention.

[0030] This embodiment is a welding method for stainless steel pipes, comprising the following steps:

[0031] ① Set the pipe fitting 2 to be welded outside a base pipe 1, and make the inserting end of the base pipe 1 protrude from the pipe fitting to be welded;

[0032] ②Insert the protruding part of the base pipe into another pipe to be welded 3, so that the welded ends of the pipe to be welded and the pipe to be welded are butted together to form the seam to be welded 4;

[0033] ③ Welding is performed at 4 places of the seam to be welded, so that the welded pipe fitting is connected to the welding end of the pipe fitting to be welded;

[0034] ④Pull out the base pipe 1 from the welded pipe fittings.

[0035] In this embodiment, the base pipe 1 is a met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com