Suspension assembly transport device

A technology for conveying devices and aggregates, which is applied in the field of devices for transporting suspension aggregates. It can solve the problems of variable weight and complex structure of the suspension aggregate handling device, and achieve the effects of simple disassembly, simple structure, and improved support strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

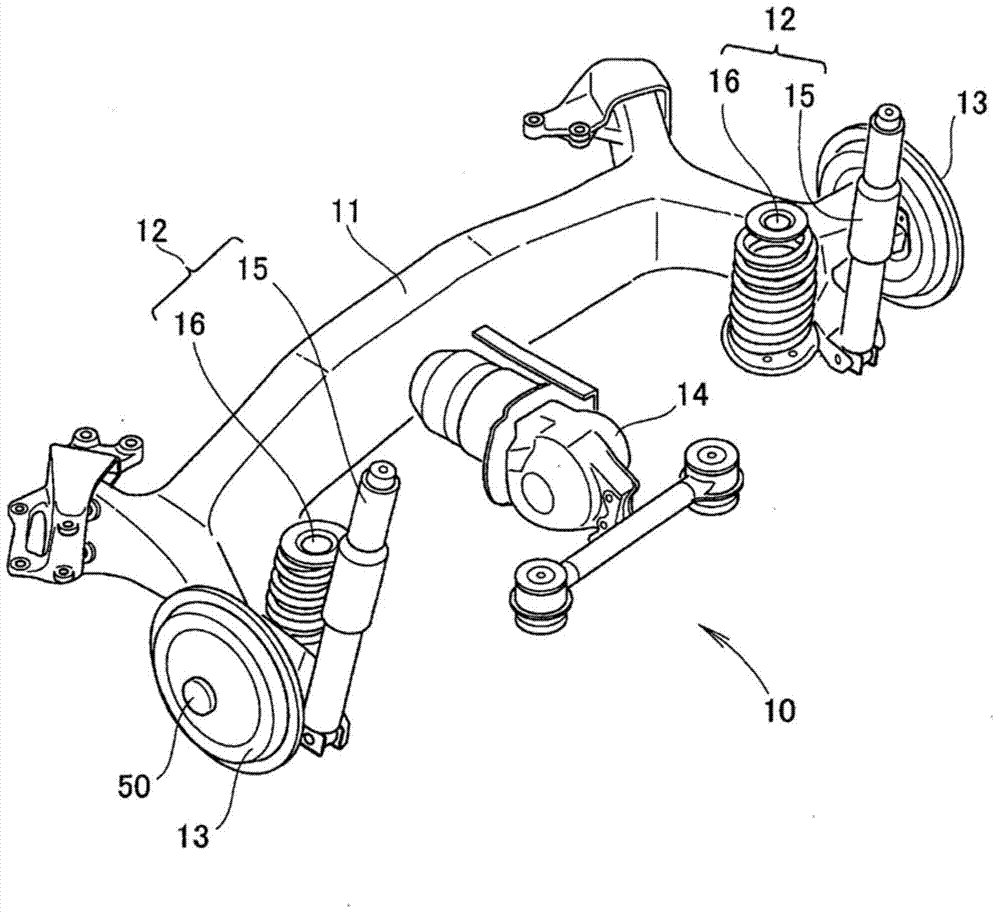

[0044] Such as figure 1 As shown, the suspension assembly 10 has: a shaft beam 11 extending along the width direction of the vehicle; left and right suspensions 12, 12 mounted on both ends of the shaft beam 11 and extending upward; left and right hubs 13, 13 , which is rotatably installed on both ends of the axle beam 11 , and the wheels are installed through a subsequent process; and a differential gear box 14 , which is arranged in the center of the axle beam 11 . Furthermore, the suspension 12 includes a shock absorber 15 and a spring 16 .

[0045] The suspension assembly 10 is preassembled at a location different from the vehicle assembly line. Since only the suspension assembly 10 needs to be attached to the vehicle body on the vehicle assembly line, the assembly work on the vehicle assembly line is simplified.

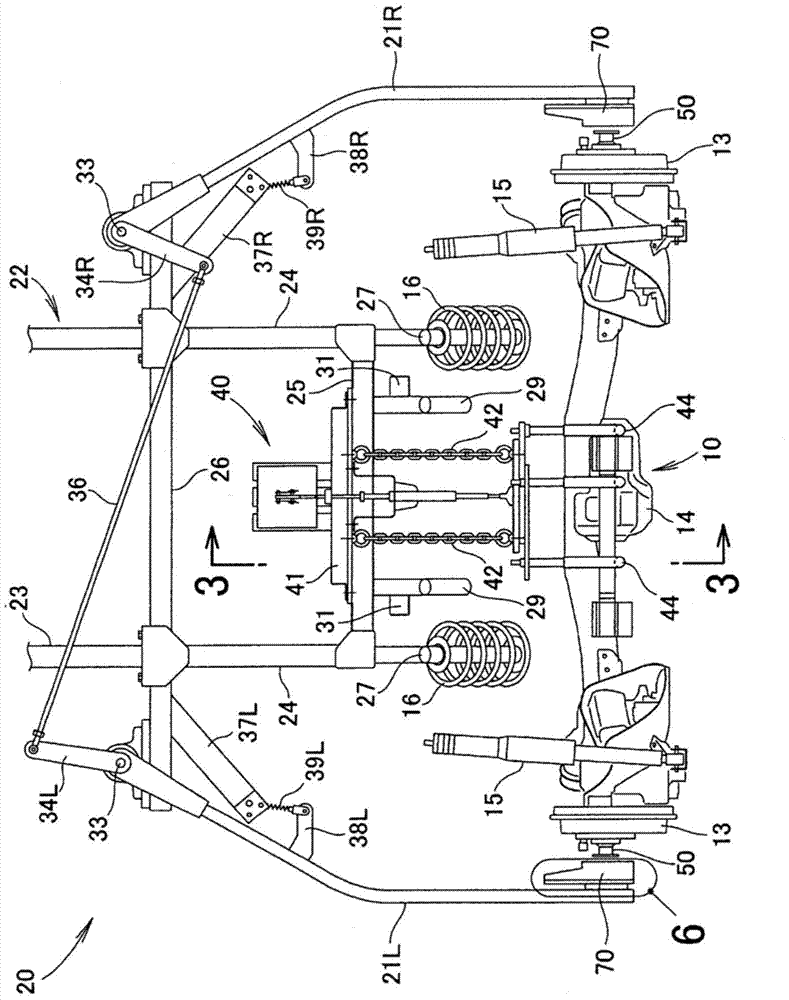

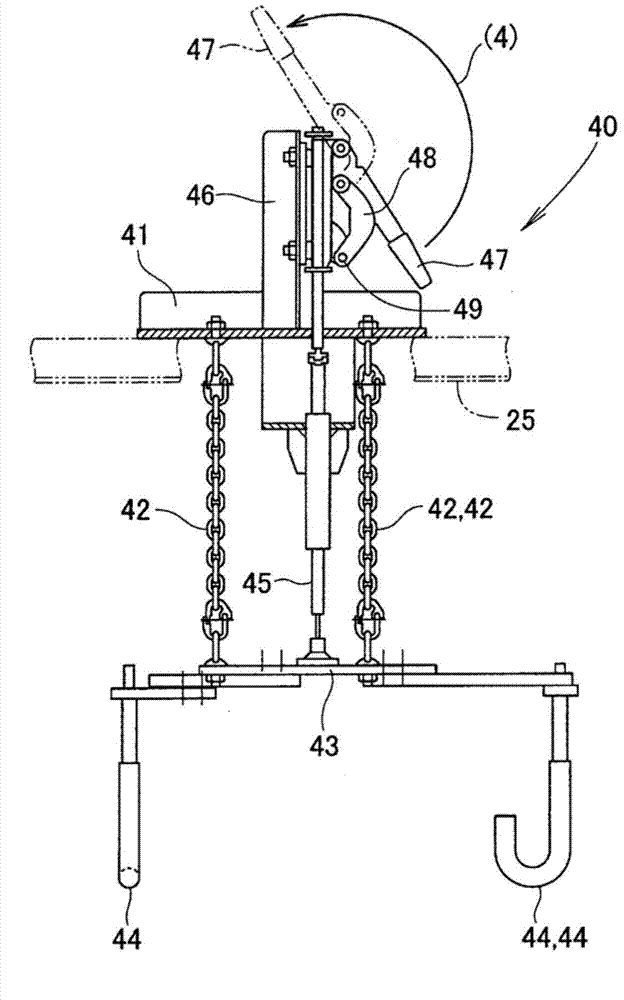

[0046] The suspension assembly 10 is transported to the vehicle assembly line. A preferable example of the suspension assembly conveyance device 20 used for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com