LED (Light Emitting Diode) strip backlight lamp

A backlight, LED aluminum substrate technology, applied in the direction of point light source, light source, electric light source, etc., can solve the problems of harmful heavy metal mercury, high calorific value, large energy consumption, etc., achieve enhanced luminous effect, prolong service life, High color rendering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

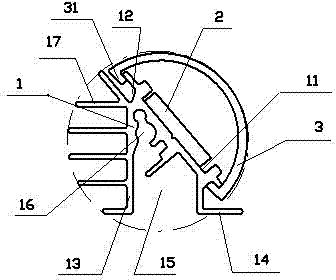

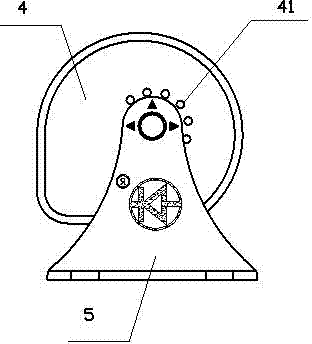

[0014] The specific implementation will be described in detail below in conjunction with the accompanying drawings: Figure 1 ~ Figure 2 One embodiment of the invention is shown. In the figure, an LED strip backlight is composed of: a lamp body 1 , an LED aluminum substrate 2 , a lampshade 3 , an end cover 4 , and a support 5 . in:

[0015] The lamp body 1 is a stretched aluminum profile, and the aluminum profile is provided with an inclined fixed panel 11. The fixed panel is provided with a concave plane corresponding to the shape of the LED aluminum substrate 2, and the two ends of the fixed panel are provided with slots 12. Both ends of the fixed panel are symmetrically provided with an outer unequal L-shaped leg 13 and an inner unequal L-shaped leg 14, and the fixed panel 11 is connected with the outer unequal L-shaped leg 13 and the inner unequal L-shaped leg. The cavity 15 surrounded by the legs 14 is a right-angled trapezoid with right-angled side openings. The angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com