Plate heat exchanger and sheet bar thereof

A plate heat exchanger and plate technology, which is applied in the field of heat exchange, can solve the problems of limited space in the length direction, difficult to meet the aspect ratio, affecting the target heat exchange efficiency, etc., to achieve large fluid flow rate and heat transfer coefficient, and simplify connection The effect of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

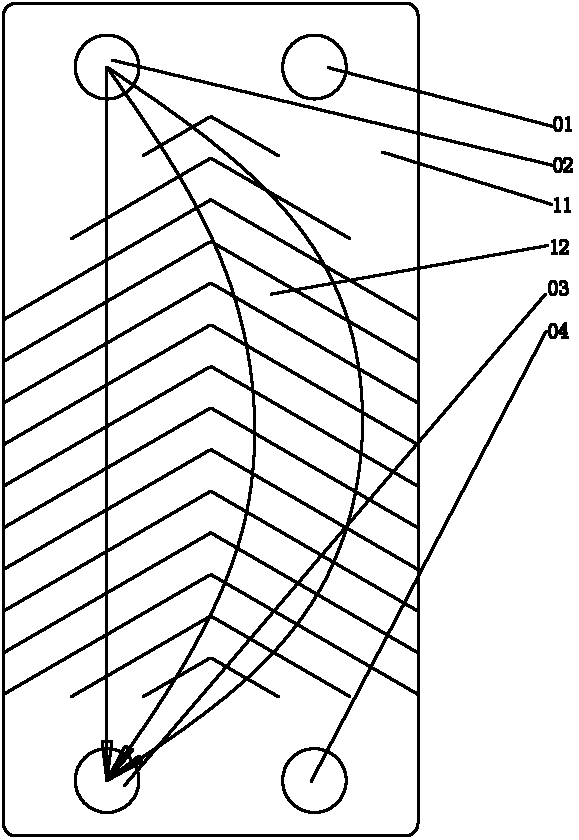

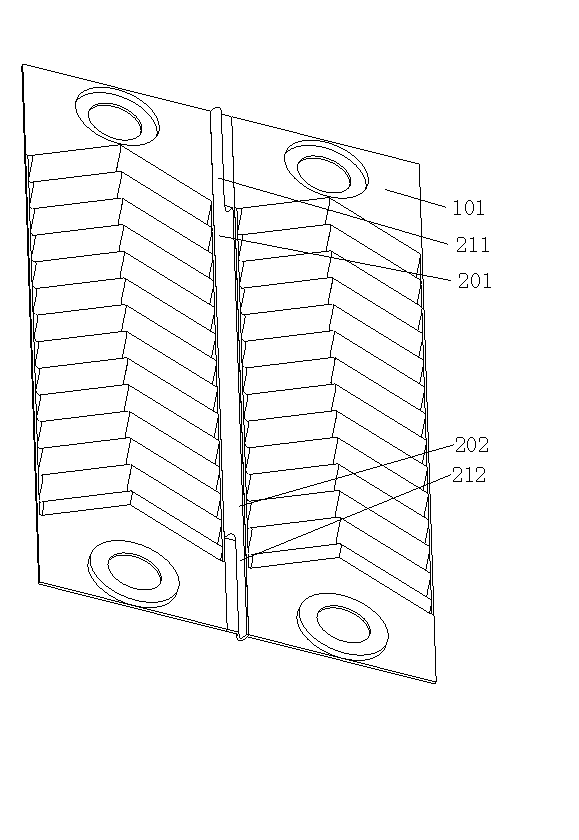

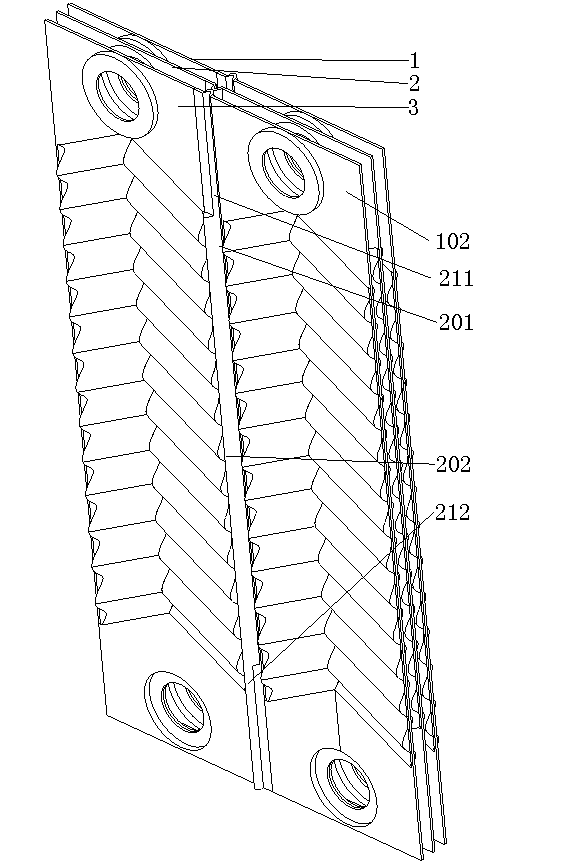

[0033] Such as figure 2 The plate of the plate heat exchanger shown, the plate includes two plate planes located on the front and back sides of the plate: the first plate plane 101 (such as figure 2 shown) and the second board plane 102 (as image 3 shown). The plate includes an isolation segment that separates the plate into at least 2 regions. The isolation segment includes a first isolation segment 211, a second isolation segment 212, and a third isolation segment. The third isolation segment includes two sections of the same length adjacent to each other. The grooves that are set and recessed in opposite directions relative to the plates: the first groove 201 and the second groove 202, the first isolation section 211 and the second isolation section 212 are located at both ends of the third isolation section; the first The isolation section 211 is an extension of the first groove 201 on the plate, and the second isolation section 212 is an extension of the second groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com