Dual probe-based angular displacement transducer on-line self-calibration method

An angular displacement sensor and self-calibration technology, which is applied in the direction of instruments, measuring devices, etc., can solve problems such as discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

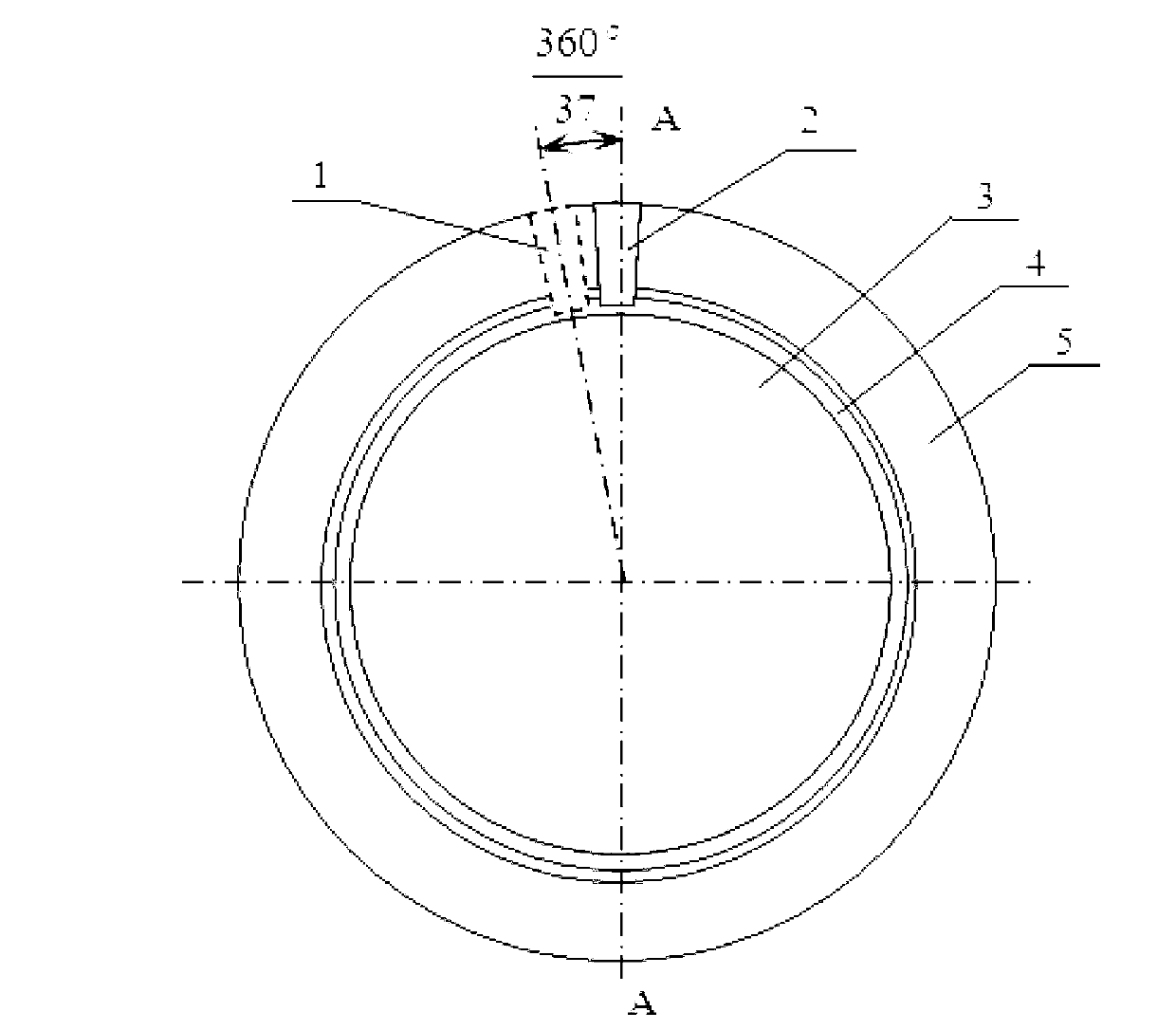

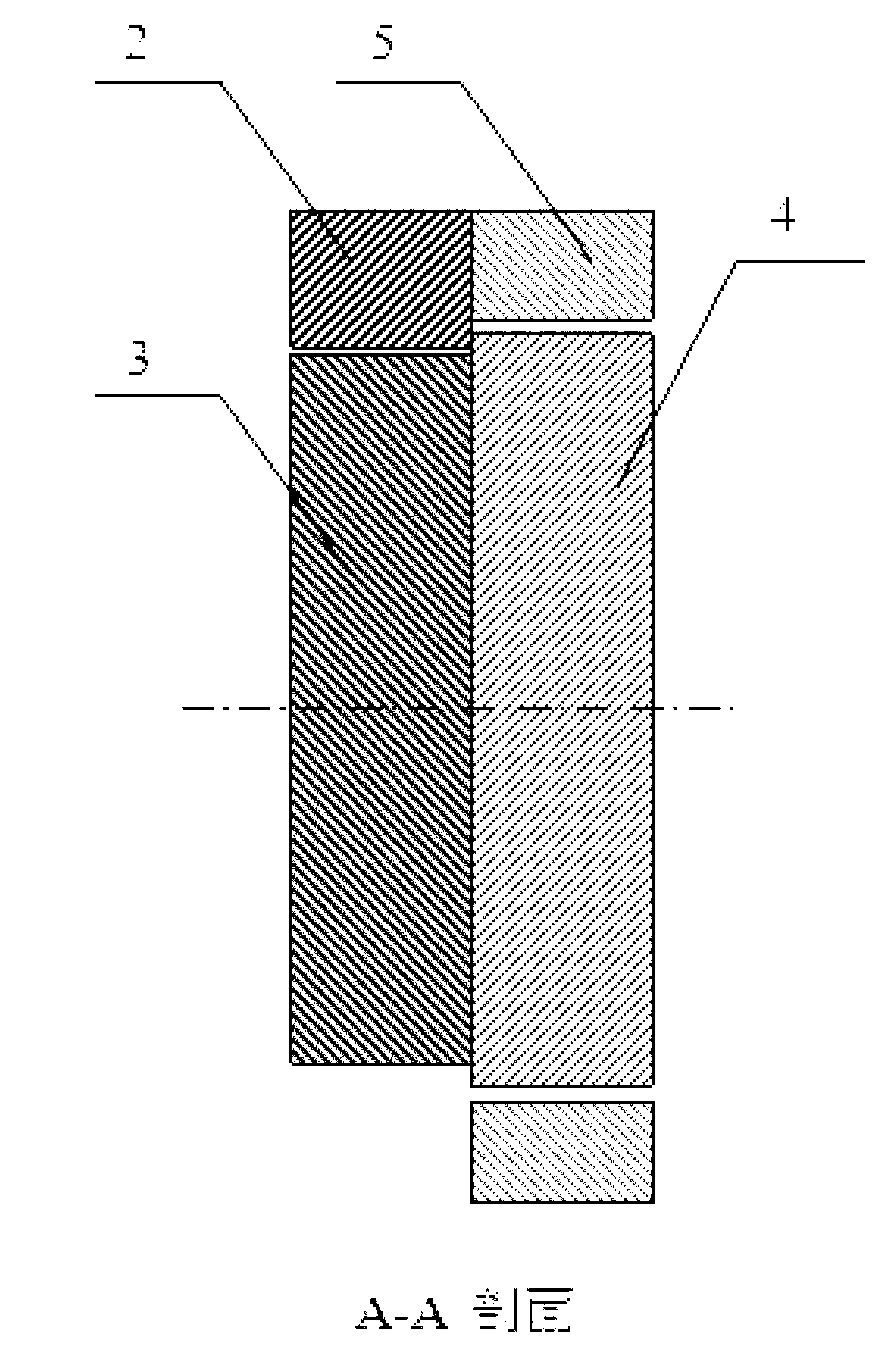

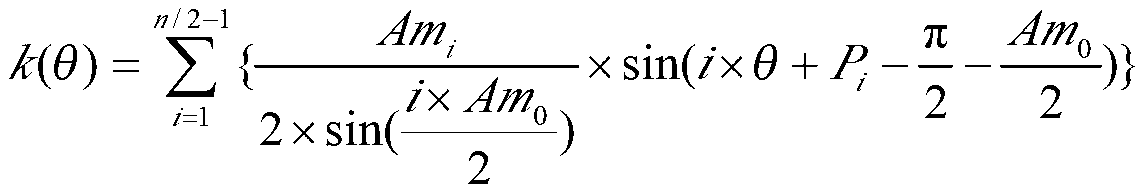

[0034] see figure 1 with figure 2 , an error online self-calibration method of an angular displacement sensor system is: in the magnetic grid sensor composed of the reading head A1, the reading head B2, the magnetic disk 3, the rotor 4 and the stator 5, the reading head A1 and the reading head B2 are arranged in the On the same circumference of the stator 5, with a distance of 33670°, the magnetic disk 3 is fixed to the rotor and fixedly connected to the rotating part of the measured object. As the measured object rotates, the two reading heads can simultaneously read the magnetic disk to realize the angle measurement of the measured object. Displacement measurement, when the measured object rotates a circle, the reading head A shows a value of 0, , respectively record the indications of reading head A and reading head B to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com