Infrared microscope system and method for achieving image fusion thereof

A technology of infrared microscopy and infrared images, which is applied in image enhancement, image data processing, radiation pyrometry, etc., can solve the problems of image detail capture without rich visible light, low imaging resolution, and limitations, so as to meet the requirements of clear imaging and Detailed analysis of the effect of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

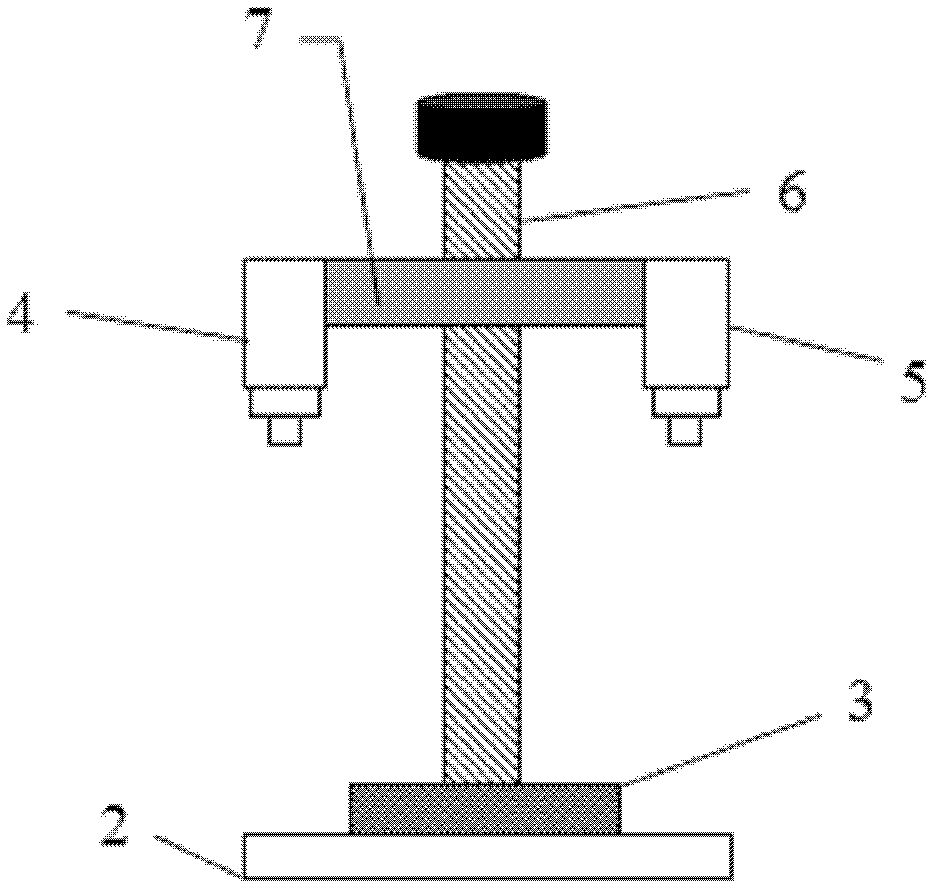

[0022] An infrared microscopic system, comprising a support, a stage 2, a target object 3, a visible microscopic camera 4 and an infrared microscopic camera 5, the target object is placed on the stage; the visible microscopic camera and the infrared microscopic camera are respectively placed on the support and above the stage, the optical axes of the visible microscopic camera and the infrared microscopic camera are parallel to each other and perpendicular to the upper side of the stage, the The visible microscopic camera and the infrared microscopic camera can move up and down and position relative to the stage along the support at the same time, and the visible microscopic camera and the infrared microscopic camera can respectively move left and right along the horizontal plane where they are located and make the Its lens is facing the target object on the stage.

[0023] Preferably, the above-mentioned visible microscopic camera and infrared microscopic camera can be moved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com