Permanent-magnet synchronous motor start-up smooth switching method

A permanent magnet synchronous motor, smooth switching technology, applied in the direction of the starting device, etc., can solve the problems of speed jitter, position and current distortion, application range limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

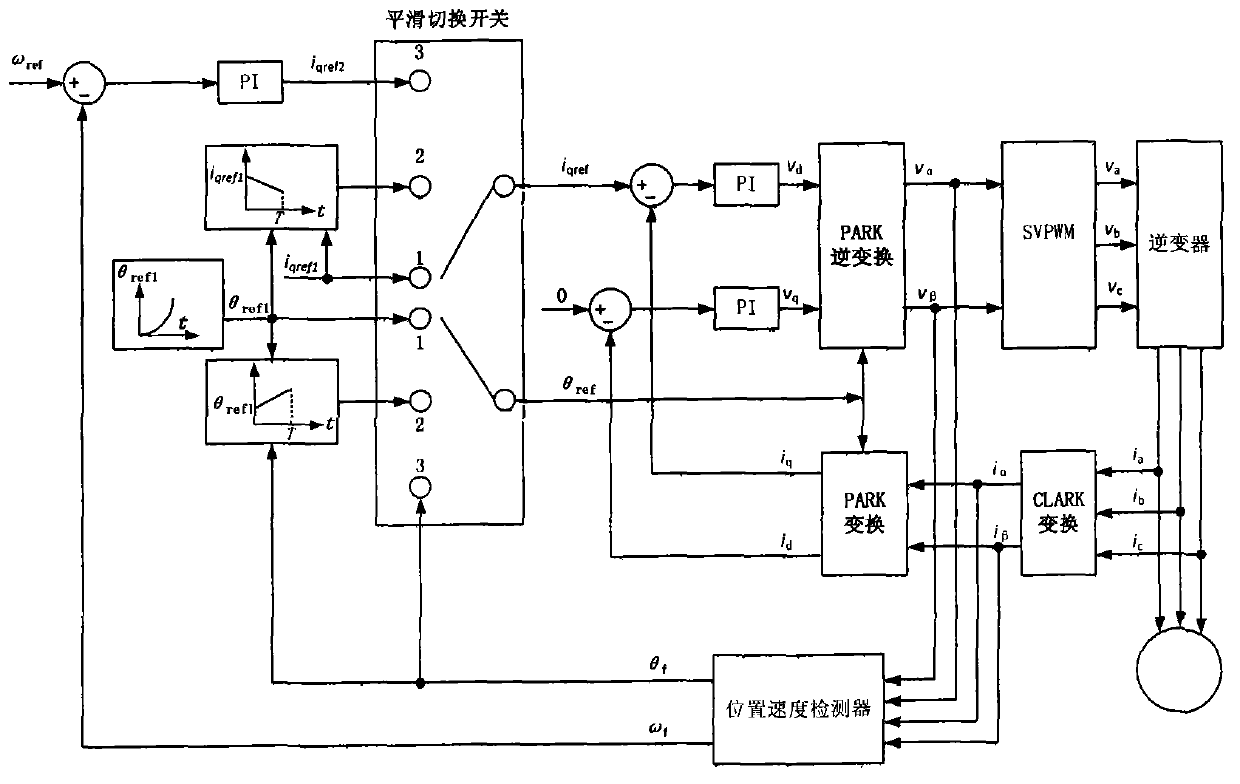

[0013] A permanent magnet synchronous motor starting smooth switching method in this embodiment, the permanent magnet synchronous motor rated power 120W, rated speed 1200rpm, speed range 400-1200rpm, including the following steps:

[0014] (1) Preset torque given current i qref1 Constantly equal to 0.9A, acceleration coefficient k=5000, switching transition time T=2s, so that the rotor has a given position angle θ ref1 Press ∫2πkt 2 dt changes, put the smooth switching switch to position 1, so that the torque current i of PARK transformation and inverse transformation qref equal to i qref1 , so that the PARK transformed and inverse transformed rotor position angle θ ref equal to theta ref1 , to force the permanent magnet synchronous motor to start and accelerate the rotation;

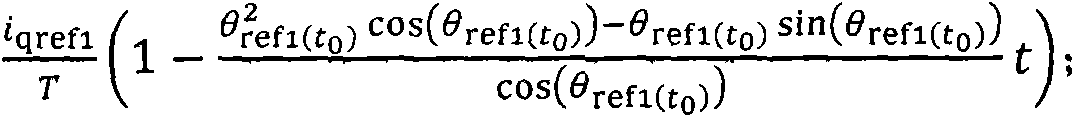

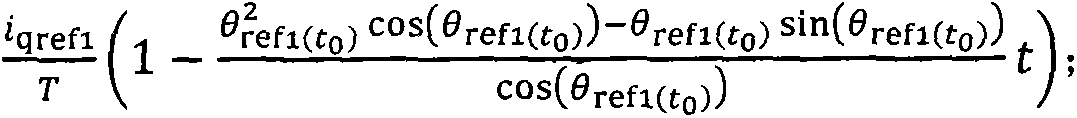

[0015] (2) When the position velocity estimator detects the permanent magnet synchronous motor velocity ω f When it reaches 360rpm, turn the smooth switch to position 2, so that the position angle...

Embodiment 2

[0018] A permanent magnet synchronous motor starting smooth switching method of the present embodiment, the permanent magnet synchronous motor rated power 60W, rated speed 900rpm, speed range 400-900rpm, including the following steps:

[0019] (1) Preset torque given current i qref1 Constantly equal to 0.5A, acceleration coefficient k=3000, switching transition time T=3s, so that the rotor has a given position angle θ ref1 Press ∫2πkt 2 dt changes, put the smooth switching switch to position 1, so that the torque current i of PARK transformation and inverse transformation qref equal to i qref1 , so that the PARK transformed and inverse transformed rotor position angle θ ref equal to theta ref1 , to force the permanent magnet synchronous motor to start and accelerate the rotation;

[0020] (2) When the position velocity estimator detects the permanent magnet synchronous motor velocity ω f When it reaches 300rpm, turn the smooth switch to position 2, so that the position a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com