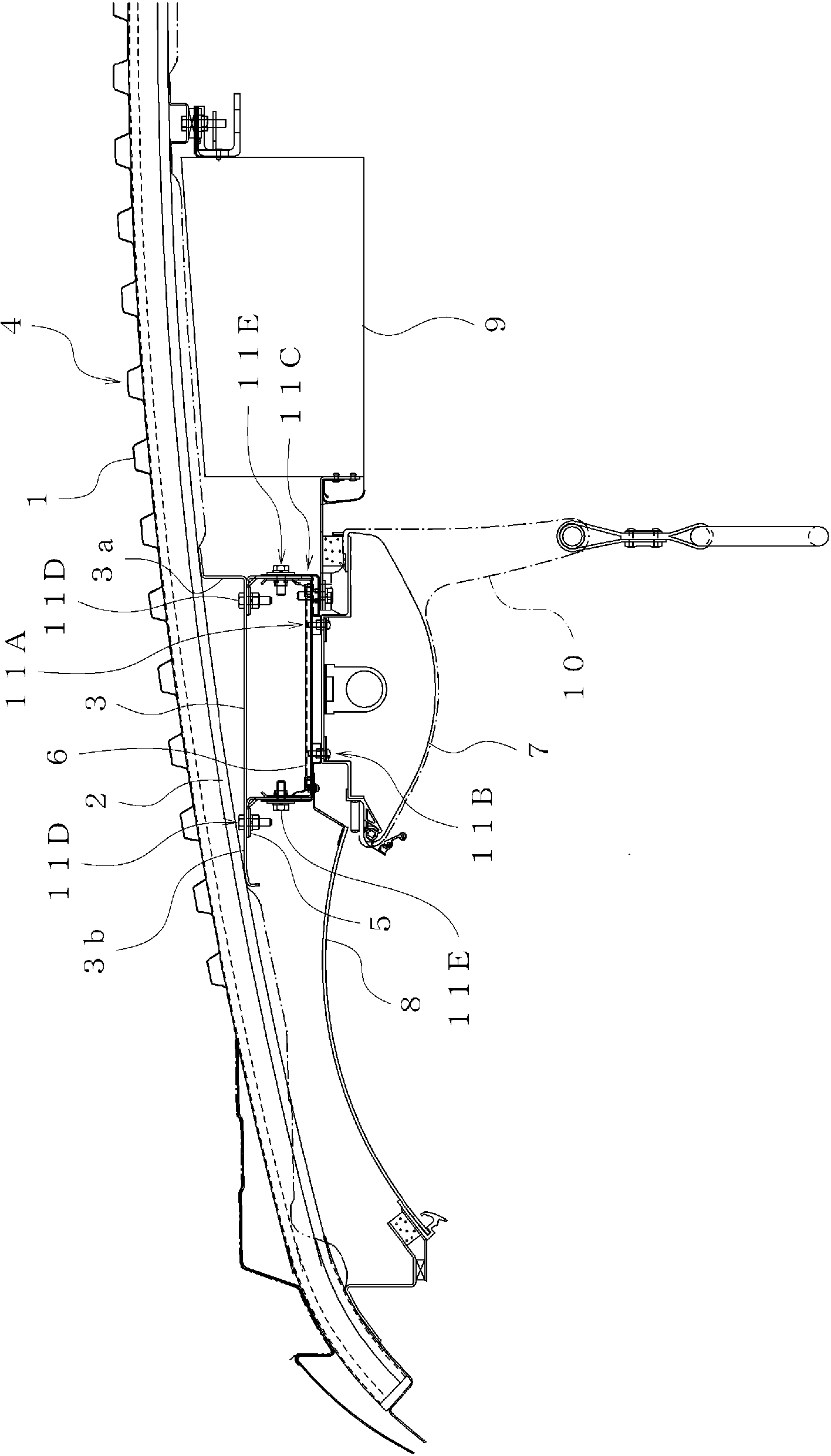

Interior article mounting structure for railway vehicle

一种内部设备、铁道车辆的技术,应用在车辆内部照明装置、铁路车辆照明装置、车辆部件等方向,能够解决调节作业费时间等问题,达到安装作业容易进行的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

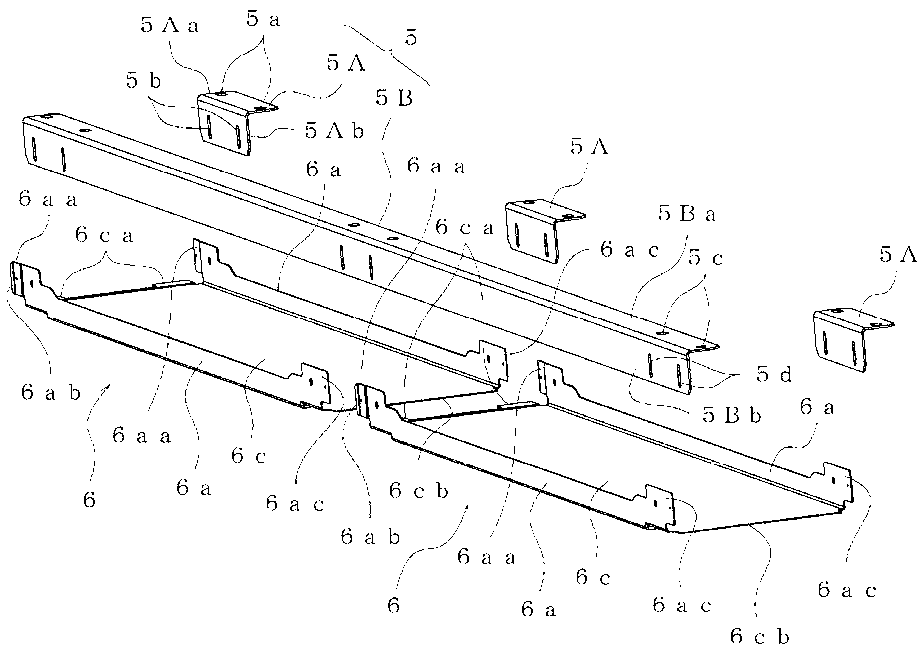

[0083] In the above embodiment, the long holes 5b and 5d for adjusting the position in the vertical direction of the vehicle are formed in the first mounting member 5 (brackets 5A, 5B), but they may be formed in the second mounting member.

Deformed example 2

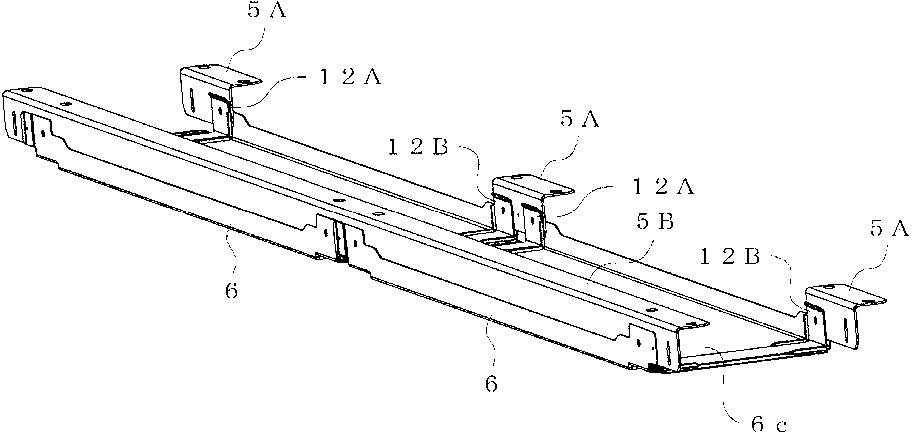

[0085] In the above embodiment, a gap S2 is formed between the flexed extension portion 12Bba of the inner member 12B and the extension portion 6cb of the second attachment member 6 into which the flexion insertion portion 6ca of the adjacent second attachment member 6 is inserted. To form such a gap, only the flexural extension 12Bba or the extension 6cb overlaps the flexion insertion portion 6ca. In addition, when the vehicle interior equipment supported by the second mounting member 6 is light, the inner members 12A and 12B (inner members) may be omitted.

Deformed example 3

[0087] In the above embodiment, the mounting direction of the first mounting member 5 (brackets 5A, 5B) is such that the longitudinal direction of the first mounting member 5 is aligned with the vehicle longitudinal direction, but it may be aligned with the vehicle width direction. For example, such as Figure 8 ~ Figure 9B As shown, the first mounting member 5 (brackets 5A, 5B) is adjusted in position with mechanical fasteners 11F and is mounted on a hanging groove 21a formed on the roof structure 21 and extending in the longitudinal direction of the vehicle so that The length direction of the mounting member is the vehicle width direction. Furthermore, elongated holes 5b and 5d are provided in the first bracket 5A and the second bracket 5B (first mounting member 5), and the first mounting member 5 and the second mounting member 6 are fastened with mechanical fasteners 11G. At this time, since the long holes 5b and 5d are used, the position can be adjusted in the vertical dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com