Advancement support device for spreading machine

A support device and paver technology, applied in the direction of steering mechanism, transportation and packaging, non-deflectable wheel steering, etc., can solve the problems of small strength, increased weight of the whole machine, insufficient, etc., to improve paving efficiency and construction quality , Guarantee the effect of levelness and continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

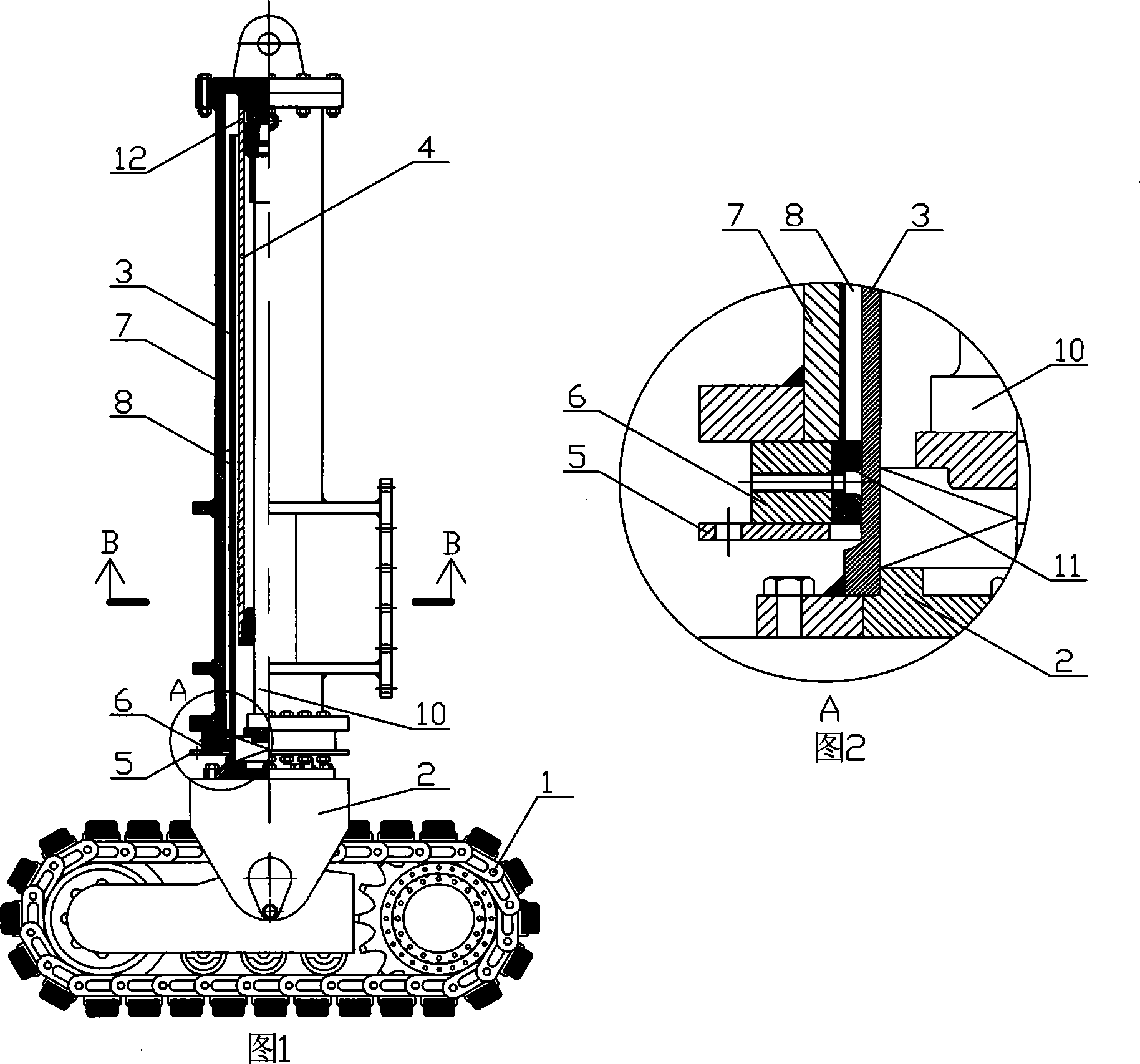

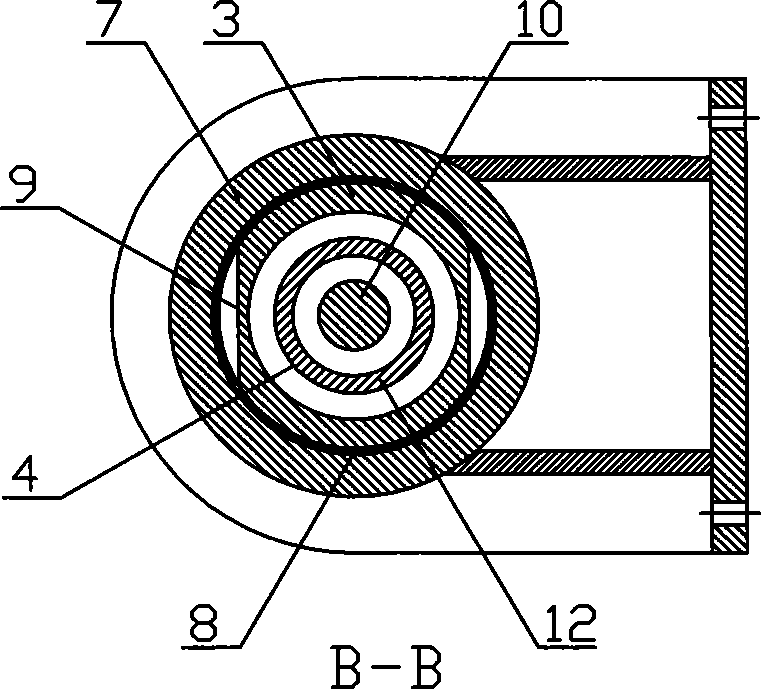

[0016] Embodiment 1: as Figure 1 to Figure 3 As shown, the paver travel support device includes driving crawler belt 1, fixed frame 2, lifting inner sleeve 3, thrust cylinder 4, slider retaining ring 5, inner sleeve lifting positioning ring 6, outer fixing sleeve 7 and reciprocating motion bearing 8. Among them, a fixed frame 2 is fixed above the drive track 1; a lifting inner sleeve 3 is vertically fixed on the fixed frame 2, and the bottom end of the lifting inner sleeve 3 is fixed on the fixed frame 2; The outer wall is provided with a relative chute 9; a thrust oil cylinder 4 is vertically provided in the inner cavity of the lifting inner sleeve 3, and the top of the push rod 10 of the thrust oil cylinder 4 is placed at the bottom of the inner cavity of the lifting inner sleeve 3; On the outer wall, the set slider retaining ring 5 is fixed; on the outer wall of the lifting inner sleeve 3 above the slider retaining ring 5, the inner sleeve lifting positioning ring 6 is sli...

Embodiment 2

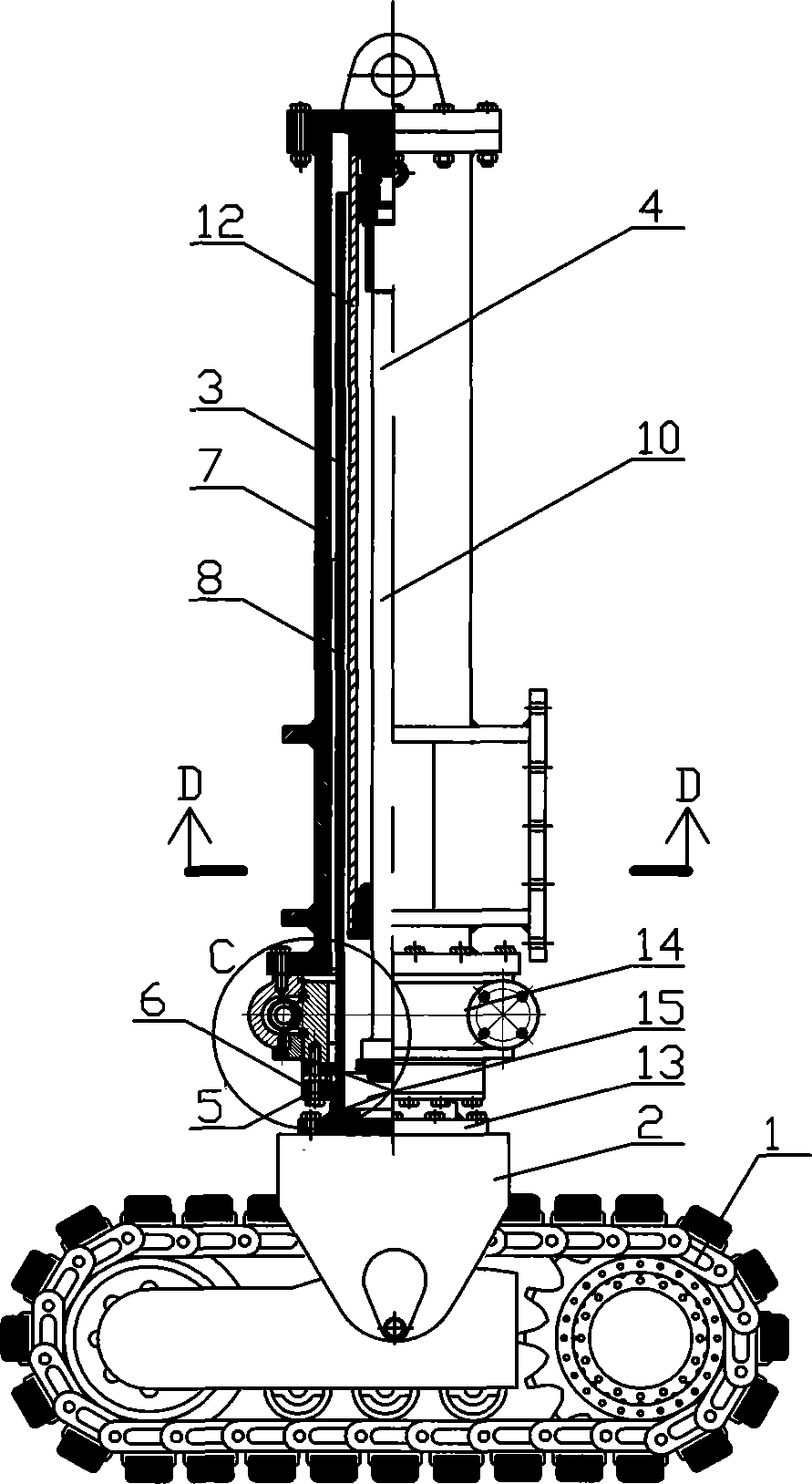

[0017] Embodiment 2: as Figure 4 to Figure 7 As shown, the paver travel steering support device includes a driving track 1, a fixed frame 2, a bearing seat 13, a lifting inner sleeve 3, a thrust cylinder 4, a slider retaining ring 5, an inner sleeve lifting positioning ring 6, and a rotary drive device 14. The outer fixed sleeve 7 and the reciprocating motion bearing 8, wherein, a fixed frame 2 is fixed above the drive track 1; a bearing seat 13 is fixed above the fixed frame 2; a bearing 15 is fixed on the bearing seat 13, and the The sliding sleeve on the side wall of the bearing 15 has a lifting inner sleeve 3, and the bottom of the lifting inner sleeve 3 is movable on the top of the bearing seat 13; the outer wall of the lifting inner sleeve 3 is provided with a relative chute 9; A thrust oil cylinder 4 is vertically arranged, and the top of the push rod 10 of the thrust oil cylinder 4 presses on the upper part of the bearing 15; The sliding sleeve on the outer wall of 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com