Mixed model flexible feeding system and method

A supply system and flexible technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., to achieve the effect of reducing the collection and distribution workers, saving the collection and distribution area, and improving the collection and distribution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

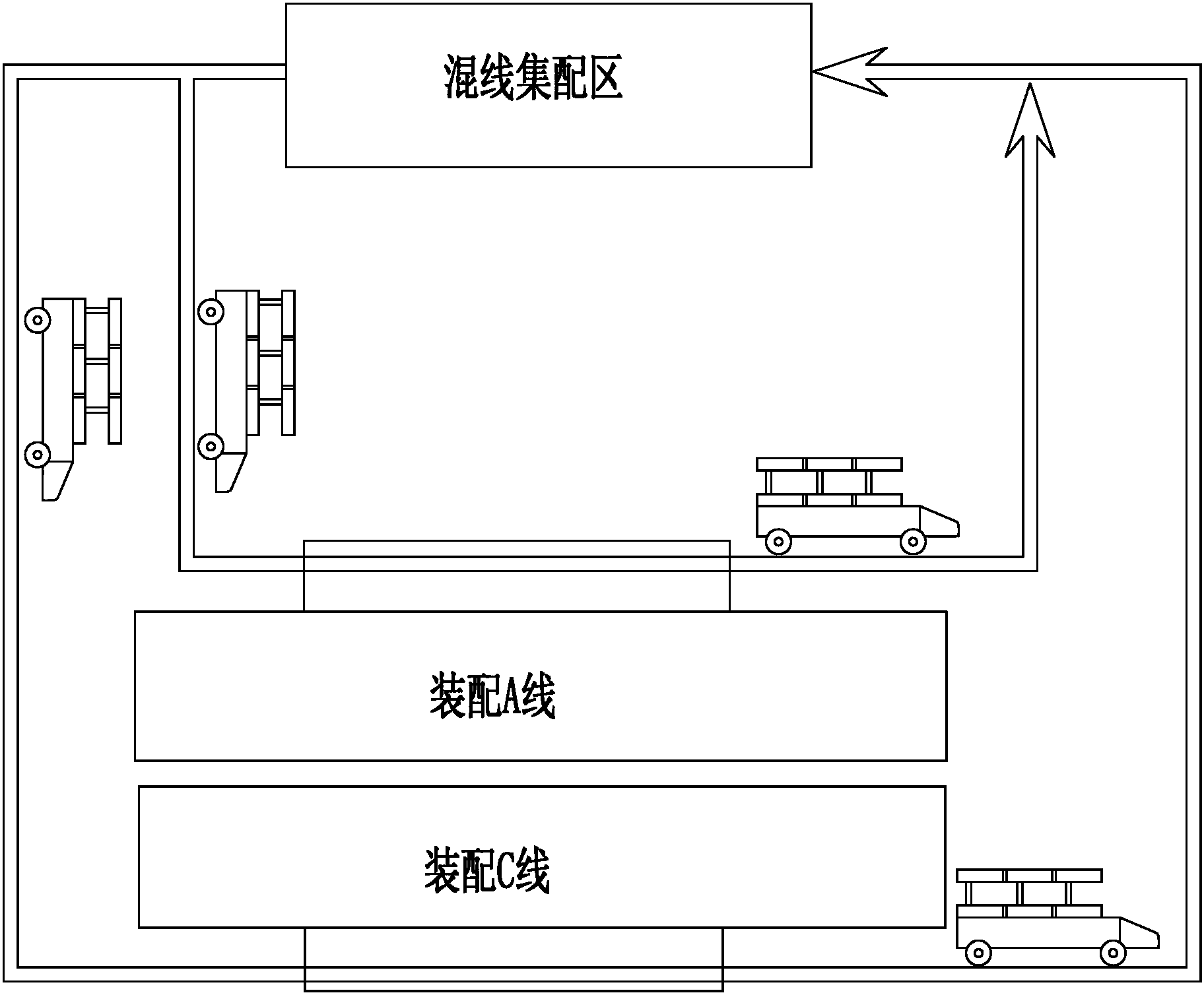

[0057] like figure 1 As shown, the mixed-line flexible supply system of this embodiment is used to realize the automatic supply of parts for two flexible automobile engine assembly production lines (assembly A line and assembly line C, hereinafter referred to as line A and line C) with one distribution area , of which A-line production models are A1, A2, A3, A4 four types of engines, C-line production models are C1, C2, C3, C4 four types of engines. The system includes a system server, a controller, a collection and distribution area, A-line material boxes and A-line automatic guided vehicles corresponding to A-line, C-line material boxes and C-line automatic guided vehicles corresponding to C-line. Among them, the difference between the A-line material box and the C-line material box is that the top of the A-line material box is provided with a light-shielding plate for photosensitive identification, while the C-line material box is not provided with a light-shielding plate. ...

Embodiment 2

[0069] The differences between this embodiment and Embodiment 1 are: (1) There are three production lines A, B, and C in the production workshop; (2) The material boxes in the collection and distribution area are transported by conveyor belts.

Embodiment 3

[0071] The difference between this embodiment and Embodiment 1 is that there are two differences between the A-line material box and the C-line material box. The C-line material box has neither a shading plate nor a bump; at the beginning and end of the material picking section, two types of material box identification devices are installed to perform double identification of the material box, and the conclusions of the double identification are consistent. Only then can you determine the production line to which the material box belongs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com